Welcome to our blog, where welding enthusiasts and DIYers come to learn and share their passion for all things metalworking! Today, we’re diving into a topic that is essential for any welder’s safety and success: how to ground a welder. Whether you’re a beginner eager to get started or a seasoned pro looking to refresh your knowledge, this guide will provide you with all the information about how to ground a welder.

So, grab your protective gear and get ready to learn the ins and outs of grounding, as we shed light on this critical aspect of welding that often goes overlooked. Don’t let sparks fly aimlessly – let’s get grounded and elevate our welding game together!

Why May You Want to Ground a Welder?

1 . To Ensure Safety

Grounding a welder is an essential safety precaution that should never be overlooked. When welding, there is always a risk of electric shock due to the high voltage used in the process. Without proper grounding, this risk increases significantly as the welding machine may become charged with electricity, posing a threat to anyone who comes in contact with it. By grounding the welder, you create a safe path for electricity to follow in case of any malfunction or electrical surge. This ensures that you and those around you are protected from potential hazards.

2 . To Protect Sensitive Electronic Equipment

Welding produces electromagnetic interference (EMI) that can damage sensitive electronic equipment nearby. By grounding the welder, excess EMI is directed towards the grounding cable instead of sensitive devices, preventing any potential damage. This is especially crucial for welding in industrial environments where there may be a lot of electronic equipment present.

3 . To Improve Weld Quality

Properly grounding a welder can also help improve the quality of your welds. When welding, it is essential to have a stable and consistent electrical current for optimal results. Without proper grounding, the welding machine may experience fluctuations in voltage, resulting in an inconsistent weld. By grounding the welder, you ensure a steady flow of electricity, leading to better and more precise welds.

How to Ground a Welder in 5 Easy Steps

Step 1: Understand the Importance of Grounding a Welder

Before we dive into the steps of grounding a welder, it’s important to understand why this step is crucial. The purpose of grounding a welder is to provide a safe path for electrical currents to flow in case of any malfunctions or accidents. This prevents electric shock and potential fire hazards, making it an essential safety measure when working with welding equipment.

Step 2: Check Your Welder’s Manual

The first thing you should do before grounding your welder is to read the instruction manual provided by the manufacturer. Every welder has different specifications and requirements, so it’s important to follow the instructions provided in the manual for proper grounding. If you no longer have the manual, most manufacturers have it available for download on their website.

Step 3: Prepare Your Equipment

To ground your welder, you will need a few tools and materials. These include:

- A grounding clamp

- A length of copper wire

- A metal stake or rod

Before starting the grounding process, ensure that all of these items are clean and in good condition to ensure a secure connection.

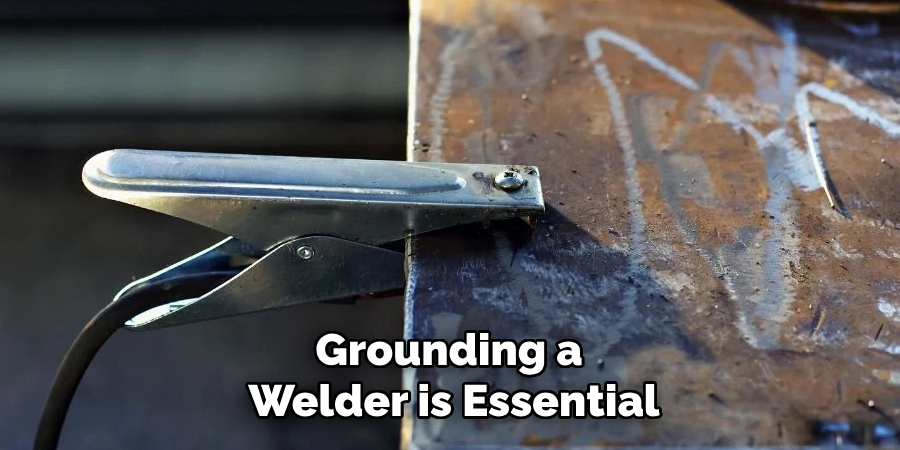

Step 4: Connect the Ground Clamp

The ground clamp is an essential component of grounding a welder. It connects the welding machine to the metal stake or rod, providing a path for electrical currents. To connect the ground clamp, first, locate the designated grounding point on your welder. This is usually indicated by a symbol of three vertical lines. Attach one end of the copper wire to the clamp and tighten it securely. Then, attach the other end of the wire to the grounding point on your welder.

Step 5: Securely Ground Your Welder

Now that your ground clamp is connected to your welder, it’s time to secure it to a metal stake or rod that has been driven into the ground. This will provide a safe path for electrical currents to flow in case of any malfunctions. Make sure the stake or rod is at least 8 feet long and is driven deep enough into the ground to ensure a secure connection. Once you have secured your welder, perform a quick test by turning on the machine and checking for any sparks or shocks. If everything looks good, you have successfully grounded your welder!

Additional Tips for Safe Welding

1 . Inspect Your Welding Equipment Regularly

As with any machinery, it’s important to regularly inspect your welding equipment for any signs of damage or wear. This includes the ground clamp and the copper wire used for grounding. If you notice any issues, replace them immediately before using the equipment.

2 . Keep Your Work Area Clean and Dry

To prevent accidents and electric shocks, it’s important to keep your work area clean and dry. This includes removing any flammable materials and ensuring there are no puddles or wet spots on the ground where you will be working.

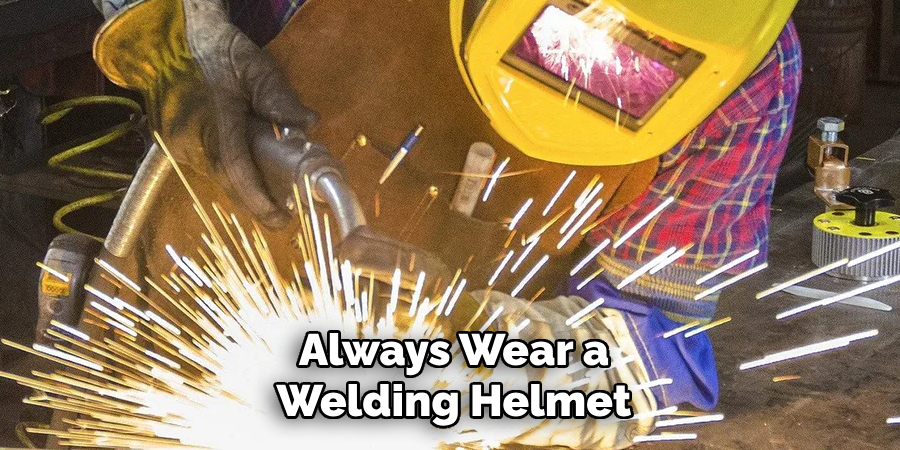

3 . Wear Protective Gear

Welding can produce sparks, fumes, and heat that can cause harm if proper protective gear is not worn. Always wear a welding helmet, gloves, and appropriate clothing to protect yourself while working.

4 . Use a Ground Fault Circuit Interrupter (GFCI)

For added safety, consider plugging your welding equipment into a GFCI outlet. This will shut off the power in case of an electrical fault, reducing the risk of electric shock. Also, make sure to regularly test your GFCI outlets to ensure they are functioning properly.

Frequently Asked Questions

What Precautions Should I Take When Grounding a Welder

When operating welding equipment, it is crucial to ensure proper grounding for the safety of yourself and others. Here are some essential precautions to keep in mind when grounding a welder:

- Always wear protective gear such as gloves, goggles, and aprons.

- Make sure that your work area is clear of any flammable materials.

Welding creates sparks and heat, which can easily cause fires.

- Ensure that your welding equipment is properly maintained and in good working condition. Faulty equipment can cause serious accidents.

- When grounding a welder, make sure it is connected to a designated ground point or a proper grounding system.

- Never touch live electrical parts while the welder is powered on.

- Do not weld on wet surfaces or in damp conditions. Water is a conductor of electricity and can cause electric shock.

- Be aware of your surroundings and avoid standing in water or touching any metal objects that may conduct electricity.

- Always follow the manufacturer’s instructions for proper grounding methods.

Why Is Grounding a Welder Important?

Grounding a welder is essential because it helps to prevent electric shock, fires, and other accidents. Welding equipment typically operates at high voltages, and without proper grounding, there is a risk of electrical shock. Grounding also helps to dissipate any static electricity that may build up during the welding process. Moreover, grounding prevents electrical overloads that can damage your equipment or cause it to malfunction. It also provides a safe path for electricity to flow, reducing the risk of electric shock or fire.

How Do I Ground a Welder?

There are several ways to ground a welder, depending on the type of welding equipment you are using. Here are some common methods:

- Connect the work clamp directly onto your workpiece. This method works well for stick welding and MIG welding.

- Use a grounding clamp to connect the work cable directly to a designated ground point. This method is commonly used for TIG welding.

- If you are using a generator to power your welder, it is essential to ensure that the generator is properly grounded.

It is crucial to follow the manufacturer’s instructions for proper grounding techniques and regularly check your equipment for any faults or damages. Overall, proper grounding is crucial for the safety and efficiency of your welding operations.

Conclusion

Grounding a welder is an essential safety measure that should not be overlooked. By following these simple steps and taking additional precautions, you can ensure a safe and accident-free welding experience.

Now you know how to ground a welder, go ahead and confidently take on your next welding project! Remember to always prioritize safety and consult the manual for any specific instructions. Happy welding! So that’s all about grounding a welder in 5 easy steps and some additional tips for safe welding. We hope this guide was helpful and informative. Stay safe and happy welding!

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.