Are you tired of your G5 Mega Meat not giving you the perfect meat cuts? It’s time to replace those dull blades and return to tender, juicy cuts.

How to replace blades on G5 Mega Meat is an essential maintenance task to ensure optimal performance and longevity of the machine. Over time, blades can become dull and inefficient, affecting the quality and speed of your grinding. By periodically changing the blades, you can guarantee smooth operation and consistent results, whether you’re processing large quantities of meat or just preparing a family meal.

In this guide, we’ll walk you through the step-by-step process of safely and effectively replacing the blades on your G5 Mega Meat grinder, allowing you to maintain peak functionality easily.

What Will You Need?

Before getting started, ensure you have the tools and materials to replace your G5 Mega Meat blades. Here’s a list of what you’ll need:

- Replacement blades designed explicitly for your G5 Mega Meat model

- Protective gloves (to avoid any accidental cuts)

- Cleaning brush or cloth

- Screwdriver (typically flathead or Phillips head, depending on your specific model)

- Safety glasses/goggles (recommended for extra precaution)

Please also refer to your G5 Mega Meat instruction manual for specific guidelines and instructions for your model. Now, let’s get started with the blade replacement process!

10 Easy Steps on How to Replace Blades on G5 Mega Meat

Step 1: Prepare Your Workspace

Ensuring your workspace is organized and safe before you begin the blade replacement process. Find a clean, flat surface with ample lighting to work comfortably. This will help you avoid any mishaps during the process. Lay down a cloth or non-slip mat to prevent small parts from rolling away and to shield delicate surfaces from scratches. Make sure all necessary tools and replacement components are within easy reach.

Wear protective gloves, and ensure that you unplug the G5 Mega Meat grinder from any power source to eliminate the risk of accidental operation. Finally, double-check that all grinder components are calm and stable, as handling a hot or unstable device could lead to accidents. Taking these preparatory measures will ensure a smooth and efficient blade replacement process.

Step 2: Disassemble the Grinder

With your workspace prepared, it’s time to disassemble the grinder to access the blades. Begin by carefully removing the hopper or lid, which is typically held in place by screws or a locking mechanism. Use the appropriate screwdriver to loosen and remove these screws, placing them safely aside for reassembly later. Gently lift the hopper away from the machine, ensuring you handle it carefully to avoid damage to any components. Once the hopper is removed, locate and detach the grinding plate and blade assembly.

It is often a straightforward process of unscrewing or sliding out parts, depending on the model. Once the blade replacement is complete, keep all removed components organized to facilitate easy and accurate reassembly.

Step 3: Remove the Old Blades

With the grinder disassembled you are now ready to remove the old, dull blades. Carefully examine how the blade is mounted within the assembly. Most blades will either slide out or must be unscrewed from their mount. If screws are securing the blade, use the appropriate screwdriver to remove them, taking care not to strip the heads. Once the blade is free, gently lift it out of its slot. Be cautious, as even dull blades can still cause injury. Set the old blade aside and clean the surrounding area using a brush or cloth to remove any leftover food particles or debris. This will ensure the new blade sits properly and functions optimally.

Step 4: Inspect the Blade Holder

Before installing the new blades, inspect the blade holder and mount for any signs of wear or damage. Look for cracks, bends, or any irregularities that might affect the stability and efficiency of the new blades. If any issues are detected, it may be necessary to replace the entire blade holder or consult your G5 Mega Meat manual for further guidance on replacement parts. Cleaning the blade holder is also essential, so ensure it’s free of any residue, using a brush or cloth to remove grime and moisture.

A clean and well-maintained blade holder provides a secure environment for attaching the new blades, maximizing their effectiveness, and ensuring safe operation of the grinder.

Step 5: Install the New Blades

Once you have inspected and cleaned the blade holder, it’s time to install the new blades. Begin by positioning the new blade inside the holder, ensuring it is aligned correctly with any guiding slots or markers. If screws secure the blade, carefully insert and tighten them to hold the blade firmly in place. Avoid over-tightening to prevent damaging the blade or its holder. Double-check that the blade is stable and does not wobble, as this could impact the performance and safety of the grinder.

With the new blades securely installed, proceed with reassembling the grinder, making sure all components are correctly aligned and fastened. This will help restore your G5 Mega Meat to optimal operating condition, ready to deliver superior meat cuts.

Step 6: Reassemble the Grinder

After installing the new blades, it’s time to reassemble your G5 Mega Meat grinder. Start by carefully placing the grinding plate and blade assembly back into their slots, ensuring they fit snugly and securely. Next, position the hopper or lid back onto the grinder, aligning it with the mounting points. Use the appropriate screwdriver to replace the screws or engage the locking mechanism, making sure not to overtighten, which could strip the screws or damage the housing. Double-check that all parts have been securely reattached and that no remaining loose components exist.

Plug the grinder back into a power source and conduct a brief test run, ensuring everything operates smoothly without unusual sounds or resistance. Your G5 Mega Meat grinder is ready for use and equipped with new blades for optimal performance.

Step 7: Test the Grinder’s Performance

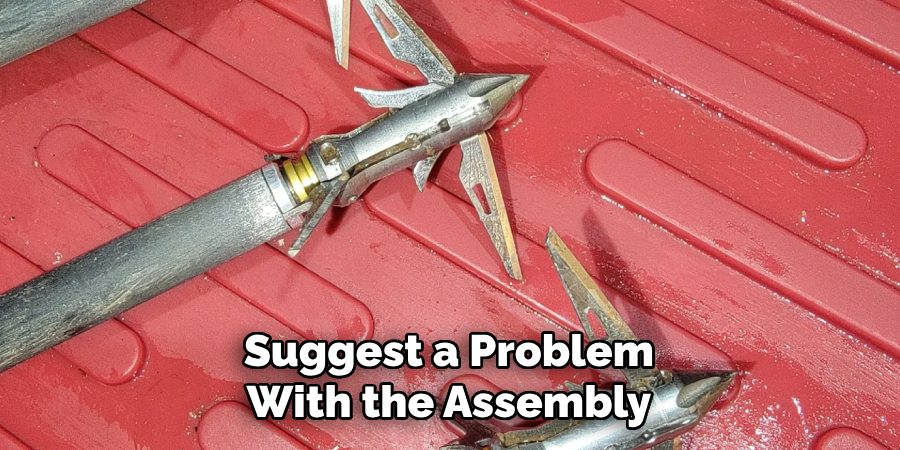

With your G5 Mega Meat grinder fully reassembled, it’s essential to test its performance to ensure the new blades function correctly. Begin by preparing a small amount of meat or another suitable substance for grinding. Feed it through the grinder slowly, observing how the machine handles the process. Pay attention to the texture and consistency of the output, which should be smooth and uniform, indicating the blades are cutting efficiently. Listen for any unusual noises that might suggest a problem with the assembly or the new blades.

If everything operates smoothly without issues, your grinder is ready to resume regular use. However, if any concerns arise, revisit the assembly steps to check for proper alignment and installation. Regularly test and maintain your grinder to keep it performing at its best.

Step 8: Maintain Your Grinder Regularly

After ensuring that your G5 Mega Meat grinder operates seamlessly after installing new blades, commit to a routine maintenance schedule to prolong the machine’s lifespan. Inspect all removable components, including the blades and grinding plate, for signs of wear or damage. Clean your grinder thoroughly after each use, paying particular attention to areas where meat residue or moisture might accumulate. This not only prevents hygiene issues but also ensures the grinder functions optimally. Depending on usage frequency, sharpen or replace the blades as required to maintain their efficiency.

Keeping the motor area free of dust and checking for any loose connections also contributes to the overall reliability of the grinder.

Step 9: Store Your Grinder Properly

Proper G5 Mega Meat grinder storage is essential to protect its components and ensure its longevity. After thoroughly cleaning and drying all parts, reassemble the grinder wholly or partially if space allows. Store it in a dry, cool place to prevent rust or corrosion on the metal parts. If your grinder has detachable components, consider storing them in a labeled container to keep them organized and reduce the risk of misplacement. Using a dust cover or placing it in a cupboard can further protect the grinder from dust and kitchen debris.

Step 10: Troubleshooting Common Issues

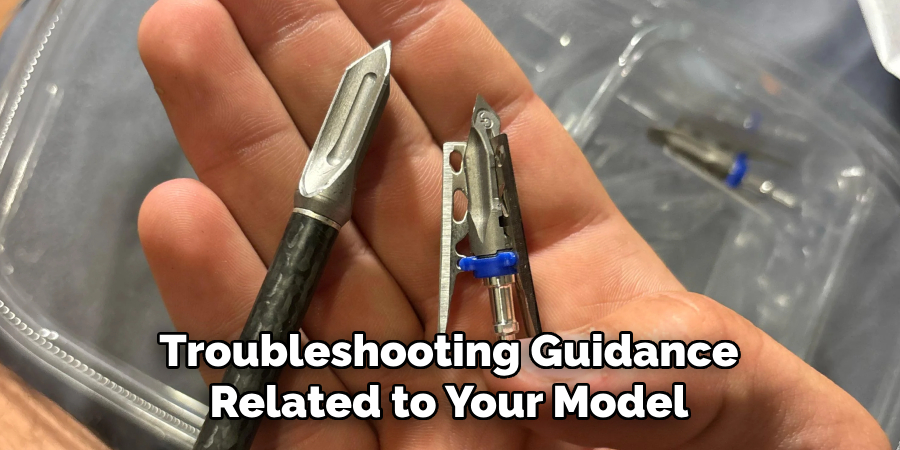

Even with careful maintenance, your G5 Mega Meat grinder may encounter issues requiring troubleshooting. Common problems include jamming, unusual noises, or inconsistent grinding. If the grinder jams, disconnect it from the power and check for obstructions in the feed tube or plate. Disassemble and clean these areas thoroughly before attempting to grind again. If you notice unusual noises, ensure all components are tightly secured, and no parts are worn or damaged. Inconsistent grinding can result from dull blades, so sharpen or replace them as needed. Refer to your manual for specific troubleshooting guidance related to your model.

Following these steps, you can install new blades and maintain your G5 Mega Meat grinder for efficient and safe operation.

Conclusion

How to replace blades on G5 Mega Meat is a crucial maintenance task that ensures the device continues to operate efficiently and safely.

You can confidently install new blades by meticulously following the outlined steps, from preparing your workspace to proper reassembly and testing. Doing so not only extends the life of your grinder but also improves its performance, providing consistent and superior meat cuts. Regular upkeep and mindful storage will further safeguard your investment, minimizing the need for frequent repairs and enhancing the grinder’s usability over time.

Remember, a well-maintained grinder provides a seamless and more enjoyable cooking experience.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.