Welded metal doors are a robust and reliable solution for a variety of structural and security needs. These doors are crafted using durable metal panels that are joined with welded seams, ensuring exceptional strength and resilience. Their construction often includes insulation, fire resistance, and weatherproofing, making them suitable for both industrial and commercial applications.

Welded metal doors, such as warehouses, factories, or secure residential buildings, are commonly used when security is a priority. They are also favored for their ability to withstand fire and extreme conditions, making them essential for high-risk or heavy-duty environments.

The purpose of this article is to guide you in properly understanding how to use welded metal doors and maintain them to ensure longevity and optimal performance. By following the outlined steps, users can maximize the functionality of these doors while addressing any installation or maintenance concerns with ease.

Features and Advantages of Welded Metal Doors

Key Features

Welded metal doors are constructed using high-quality metal panels joined by seamless welding, providing exceptional durability and structural integrity. This robust design ensures the doors can withstand heavy use and harsh environments without compromising strength.

Many welded metal doors are equipped with insulation options, offering energy efficiency and noise reduction. Additional features, such as fireproofing and weather resistance, make these doors suitable for various applications, including fire-rated settings and locations exposed to extreme weather conditions.

Benefits of Welded Metal Doors

The security offered by welded metal doors is unmatched, as their sturdy construction deters break-ins and unauthorized access. These doors are designed for longevity, resisting corrosion, wear, and tear over time, even in demanding environments.

Additionally, welded metal doors can be customized to meet specific needs, such as incorporating windows for visibility, selecting unique finishes for aesthetics, or applying specialized coatings for added protection. Their versatility makes them an ideal choice for both commercial and industrial purposes.

How to Use Welded Metal Door: Installing a Welded Metal Door

Preparation for Installation

To ensure a successful installation of a welded metal door, precise door frame measurements are crucial. Accurately measure the height, width, and depth of the frame to confirm the door will fit snugly without gaps that compromise security or energy efficiency.

Additionally, inspect the wall structure where the door will be installed to verify it can support the door’s heavyweight. Reinforcing the frame or wall may be necessary for optimal stability. Proper preparation simplifies the installation process and ensures the door functions smoothly and securely in the long term.

Installation Process

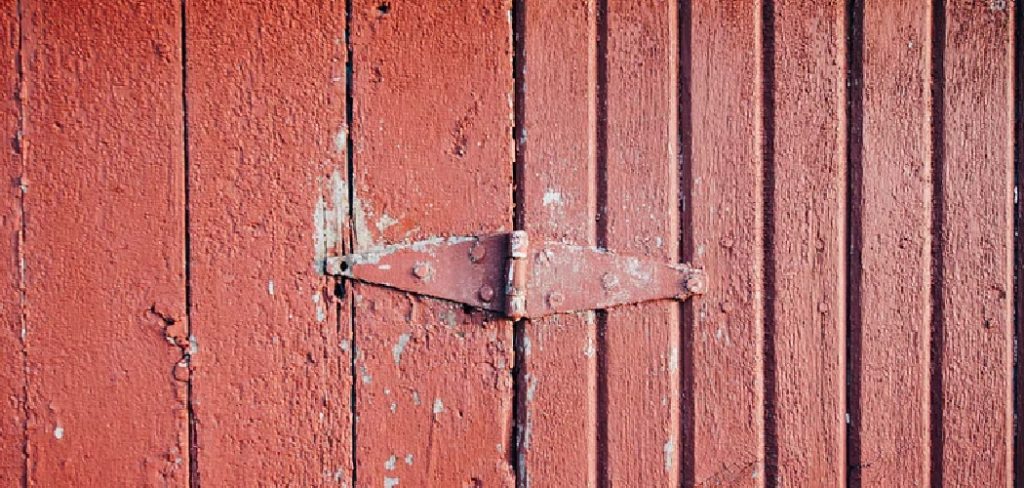

Begin the installation by carefully attaching the hinges to both the door and the frame, ensuring proper alignment for smooth operation. Secure the frame by anchoring it firmly to the surrounding wall structure and verify that it is level. Once the frame is in place, mount the door onto the hinges and make further adjustments to align it correctly.

Professional installation is strongly recommended for welded metal doors, as their heavy-duty design requires expertise to ensure both safety and functionality. Improper installation can lead to operational issues or reduced security, making professional assistance a valuable investment.

How to Use Welded Metal Door: Operating a Welded Metal Door

Opening and Closing the Door

Operating a welded metal door requires careful attention to ensure smooth and safe operation, given the door’s heavy-duty construction. One key aspect of proper operation is maintaining smooth hinge movement. Well-lubricated hinges reduce wear and tear, making opening and closing the door easier without exerting excessive force.

Regular lubrication and inspection of the hinges for any signs of damage or rust are essential to prevent operational issues. Additionally, avoid slamming the door, as excessive force can damage the frame or misalign the hinges over time.

Heavy metal doors should be opened and closed with steady, controlled motions to preserve their structural integrity and functionality. Proper operation not only enhances the door’s longevity but also ensures users’ safety, especially in high-traffic or industrial environments where the doors are frequently used.

Using Locks and Security Features

Welded metal doors are typically equipped with advanced locking mechanisms to provide enhanced security. Common types of locks include deadbolts for robust manual security, electronic locks for convenient access control, and panic bars for emergency exit compliance.

To engage a lock securely, ensure the door is fully closed and aligned with the frame, as misalignment can compromise locking effectiveness. Deadbolts should be turned fully into the locked position, while electronic locks require proper programming and user authentication for safe operation.

For panic bars, test the mechanism regularly to ensure smooth operation during emergencies. When disengaging locks, use the appropriate key, code, or access method without forcing the mechanism, as this can cause damage. By following these steps and maintaining the locking system regularly, users can ensure optimal performance and security, further reinforcing the reliability of welded metal doors.

Maintenance Tips for Welded Metal Doors

Regular Cleaning and Lubrication

Routine cleaning is essential to maximize the lifespan and performance of welded metal doors. To remove dirt, grime, and debris, begin by wiping metal surfaces with a soft cloth or sponge soaked in a mild detergent solution. Avoid using abrasive chemicals or tools that could scratch or damage the finish.

A non-abrasive metal cleaner can be applied sparingly for stubborn stains or spots. After cleaning, thoroughly dry the surface to prevent moisture buildup, which can lead to rust. Applying a protective wax or sealant periodically can provide additional resistance against corrosion.

Hinge and lock maintenance are equally critical for ensuring smooth operation. Lubricate the hinges regularly using a high-quality silicone or graphite lubricant to reduce friction and prevent squeaking.

Apply a small amount of lubricant to locks and mechanisms as well, ensuring they operate effortlessly without jamming. By keeping surfaces clean and components well-lubricated, users can prevent premature wear and promote the door’s functionality over time.

Inspecting for Damage

Frequent inspections are necessary to identify early signs of wear or damage on welded metal doors. Begin by examining the door’s surface for indications of rust, dents, or cracks that could compromise its structural integrity.

Pay close attention to any painted or coated areas, checking for peeling or flaking that might expose the underlying metal to corrosion. Inspect hinges and locks for loose screws, misalignment, or visible damage that could hinder proper operation.

Addressing issues promptly is vital to maintaining the door’s reliability and safety. Small cracks or rust spots should be treated immediately with touch-up paint or rust-resistant primers to prevent further degradation.

Tighten any loose hardware and replace damaged components to avoid more significant problems. By conducting regular inspections and implementing timely repairs, users can ensure their welded metal doors remain secure, functional, and durable under various conditions.

Troubleshooting Common Issues

Addressing Door Alignment Problems

Misaligned metal doors can cause difficulty opening and closing or compromise security. Common causes of misalignment include gradual wear and tear, improper installation, or structural shifts in the surrounding wall or frame. Hinge-related issues, such as loose screws or worn-out components, are also frequent contributors.

To fix alignment problems, first, inspect the hinges for looseness or damage. Tighten any loose screws and replace worn hinges if needed. If the frame is misaligned, use shims or adjust the anchoring bolts to level it properly.

Professional assistance may be necessary for significant issues to avoid further structural damage. Regular maintenance and inspections can help prevent alignment problems, ensuring the door operates efficiently over time.

Resolving Lock Malfunctions

Lock malfunctions, such as jamming or failure to engage properly, often stem from debris buildup, worn mechanisms, or alignment issues with the door and frame. To address a jammed lock, clean and lubricate the locking mechanism using a suitable lubricant, like graphite. If this does not resolve the problem, inspect the lock for visible damage or worn parts.

For broken components, replacing the lock mechanism may be the best solution. Ensure proper installation and test the new lock thoroughly to confirm smooth operation. Seek professional help for electronic locks or complex repairs to guarantee optimal security and performance. Regularly maintaining locks can prevent malfunctions and extend their lifespan.

Enhancing the Use of Welded Metal Doors

Adding Features for Specific Needs

Additional features can be installed to adapt welded metal doors for specific applications to improve their functionality or durability. Kickplates are useful in preventing damage to the lower portion of doors in high-traffic areas, while weatherstripping provides an effective barrier against drafts, moisture, and insects, enhancing energy efficiency.

Soundproofing materials such as acoustic seals can be incorporated into the door assembly for environments requiring noise reduction. Additionally, using high-quality paint or specialized finishes enhances both aesthetics and protection. For example, anti-corrosion coatings or powder finishes provide extra resilience against harsh weather or chemicals, extending the door’s lifespan and appearance.

Ensuring Safe Usage

Safety is paramount when operating welded metal doors, especially in industrial or heavy-duty settings. Users should always ensure the door is properly balanced and avoid placing excessive force on its components. Workplaces must offer training on handling specialized doors, such as fire-rated or panic exit models, to guarantee safe and compliant operation.

Regular maintenance is key to preventing mechanical issues that could pose hazards, and all safety mechanisms—like emergency release systems—should be tested frequently. Businesses and individuals can ensure welded metal doors function safely and efficiently by fostering proper usage practices and providing adequate training.

Conclusion

Welded metal doors provide unmatched security, durability, and versatility, making them essential for various residential, commercial, and industrial applications.

Their robust construction ensures longevity, while tailored features like weatherstripping, soundproofing, and specialized finishes enhance their functionality and appeal. Proper installation, operation, and regular maintenance—ensuring alignment, cleanliness, and well-lubricated components—are key to maximizing their performance.

Understanding how to use welded metal door systems effectively ensures they remain reliable and safe over time. By adopting best practices and addressing issues promptly, users can optimize these doors to meet specific needs, maintaining their value as a dependable solution for generations.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.