The pinion angle is a crucial component of the driveline system that plays a significant role in ensuring smooth power transfer and minimizing vibrations. It refers to the angle between the driveshaft and the differential pinion gear. Maintaining the correct pinion angle is essential for optimal driveline operation and overall vehicle performance.

Correct pinion angle alignment allows for proper driveshaft rotation, minimizing wear on components such as U-joints and preventing premature driveline failure. By ensuring that the driveline is operating at the recommended angle, vibrations during acceleration can be reduced, resulting in a smoother and more comfortable driving experience.

There are various reasons why measuring the pinion angle is important. Suspension modifications, driveline repairs, or even changes in load can affect the pinion angle, leading to driveline vibrations and potential damage. Regularly checking and adjusting the pinion angle can help identify and rectify any misalignments, maintaining the integrity of the driveline system.

To find the pinion angle, one can use specialized tools or consult a professional for accurate measurements. Taking the time to measure and adjust the pinion angle will ensure efficient power transfer, reduced driveline wear, and a more enjoyable driving experience. So keep reading to learn more about how to find pinion angle.

Tools and Materials Needed

To accurately measure and adjust the pinion angle, you will need the following tools and materials:

Tools

- Angle finder or digital inclinometer: These tools are essential for obtaining precise angle measurements.

- Floor jack and jack stands: These will allow you to safely lift and support the vehicle during the measurement process.

- Measuring tape: This tool is useful for verifying driveline distances and making accurate calculations.

Materials

- Reference guide or vehicle manual: Consult these resources to determine your vehicle’s ideal pinion angle specifications.

- Pen and paper: Use these to record your measurements and make calculations as needed.

These tools and materials will ensure that you can accurately measure the pinion angle and make any necessary adjustments for optimal driveline performance and longevity.

Preparing the Vehicle for Measurement

Before measuring and adjusting the pinion angle, it is crucial to prepare the vehicle to ensure accurate and reliable results. Follow these steps to properly set up the driveline for measurement:

Safety First:

- Park the vehicle on a level surface to ensure accurate measurements.

- Engage the parking brake to prevent the vehicle from rolling.

- Use wheel chocks to provide additional stability and prevent any unintended movement.

Lifting the Vehicle (if needed):

- If necessary, lift the vehicle using a floor jack and secure it with jack stands. Ensure that the suspension is at its natural ride height to obtain precise measurements.

Setting Up the Driveline:

- Confirm that the vehicle’s suspension is loaded as it would be under normal driving conditions. This helps simulate real-world scenarios and provides accurate measurements.

- Remove any obstacles or components that may interfere with the measurement process, such as exhaust components or skid plates.

By following these preparation steps, you can ensure a safe and controlled environment for measuring and adjusting your vehicle’s pinion angle, leading to improved driveline performance and longevity.

Measuring the Driveshaft Angle

To accurately measure the driveshaft angle, follow these steps:

Locating the Driveshaft

Identify the driveshaft connecting the transmission to the rear differential. Ensure the surface of the driveshaft is clean for accurate readings. If it is dirty or obstructed, clean it before proceeding with the measurement.

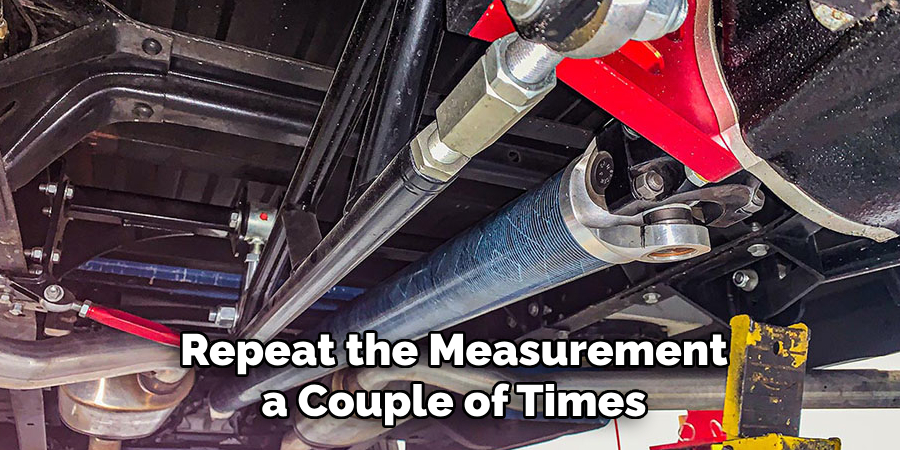

Taking the Measurement

- Place the angle finder or inclinometer on the driveshaft, making sure it sits parallel to the surface of the tube.

- Record the angle reading displayed on the tool. This measurement represents the current angle of the driveshaft.

- To ensure accuracy, repeat the measurement a couple of times and compare the readings for consistency.

By measuring the driveshaft angle, you can assess its alignment and make necessary adjustments to optimize driveline performance.

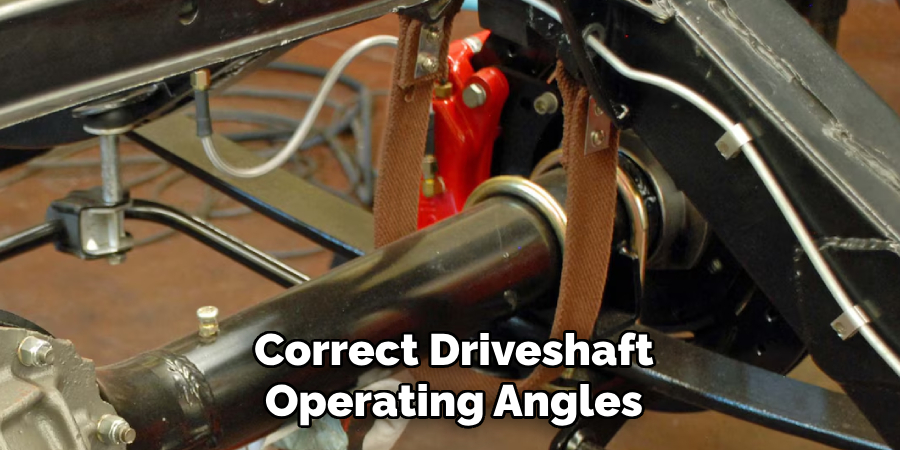

Measuring the Pinion Angle

To achieve optimal driveline performance, it is crucial to measure and adjust your vehicle’s pinion angle. The pinion angle is the angle between the driveshaft and the pinion yoke, where the driveshaft connects to the rear differential. Ensuring proper alignment can minimize vibration, reduce wear and tear on driveline components, and enhance overall vehicle performance.

Locating the Pinion Yoke

Start by identifying the pinion yoke, which is the part where the driveshaft attaches to the rear differential. A clean and unobstructed surface is essential for accurate measurements. Clean the yoke before proceeding with the measurement to ensure proper contact with the angle finder.

Measuring the Pinion Angle

- Place the angle finder on the flat surface of the pinion yoke, ensuring it sits parallel to the driveshaft.

- Note the angle reading displayed on the tool. If the angle tilts upward or downward relative to the driveshaft, note the direction.

- Repeat the measurement a few times for accurate results and compare the readings for consistency.

Measuring the pinion angle allows you to assess the alignment of your driveline and make any necessary adjustments. By optimizing the pinion angle, you can enhance driveline performance, reduce vibrations, and extend the longevity of your vehicle’s components.

How to Find Pinion Angle: Calculating the Pinion Angle

To accurately determine the pinion angle, it is essential to understand the desired relationship between the pinion angle and the transmission output shaft angle. For leaf spring suspensions, the goal is to achieve a parallel relationship between the pinion angle and the transmission output shaft angle. This alignment helps maintain optimal driveline performance and reduces vibrations. On the other hand, for vehicles with lift kits or modified suspensions, it is crucial to maintain the proper offset between the pinion angle and the transmission output shaft angle.

Understanding the Desired Relationship:

The pinion and driveshaft angles relate to the transmission output shaft angles. The driveline operates smoothly when the pinion angle is parallel to the transmission output shaft angle. This parallel relationship helps maintain the correct driveshaft operating angles and prevents unnecessary wear and tear on the driveline components.

Performing the Calculation:

To calculate the pinion angle, subtract the driveshaft angle from the pinion angle. For example, if the pinion angle is 3 degrees upward and the driveshaft angle is 1 degree downward, the pinion angle offset would be 4 degrees upward. This calculation clearly explains the relationship between the pinion angle and the driveshaft angle.

Adjusting for Lift or Custom Suspensions:

Changes in the vehicle’s geometry can affect the driveline angles when installing lift kits or modifying suspensions. It is crucial to account for these changes to ensure a safe driveline angle and prevent issues such as binding or vibration. Consult the manufacturer’s guidelines or work with a professional to determine the appropriate pinion angle offset for your specific lift or custom suspension setup. This adjustment ensures optimal driveline performance and minimizes potential driveline-related problems.

By carefully calculating and adjusting the pinion angle, you can ensure proper driveline alignment and enhance your vehicle’s components’ overall performance and longevity.

Adjusting Pinion Angle

Adjustable suspension components, such as control arms or shims, can be utilized to achieve the correct pinion angle. These components allow you to alter the pinion angle according to your specific requirements, fine-tuning the angle and optimizing driveline performance.

Using Adjustable Suspension Components:

To adjust the pinion angle, follow these steps:

- Identify the specific adjustable suspension components required for your vehicle’s setup.

- Consult the manufacturer’s guidelines or seek professional advice to make adjustments.

- Install the adjustable suspension components as per the manufacturer’s instructions.

- Gradually adjust to achieve the desired pinion angle, ensuring each adjustment is made symmetrically to maintain proper driveline alignment.

Retesting After Adjustment:

After adjusting the pinion angle, it is crucial to re-measure and retest to ensure the final angle aligns with the manufacturer’s or expert-recommended specifications. This step is essential to confirm that the driveline is properly aligned and functioning optimally. Regularly inspecting and retesting the pinion angle after adjustments or modifications will help maintain driveline performance and prevent potential driveline-related issues in the long run. Remember, consulting a professional for complex cases or utilizing advanced tools for precision can further enhance the accuracy of the pinion angle adjustments.

Troubleshooting Common Issues

It’s important to be aware of common issues that may arise with the pinion angle and driveline. Here are some troubleshooting tips to help you address these problems:

- Signs of Incorrect Pinion Angle: If you notice vibrations during acceleration, experience premature driveline wear, or observe damaged U-joints, these could be indicators of an incorrect pinion angle.

- Solutions for Persistent Issues: If you encounter persistent issues with the pinion angle, it’s advisable to consult a professional, especially for complex cases that require specialized knowledge. Using advanced tools for precision adjustments can also be beneficial in certain scenarios.

Remember, correctly aligning the pinion angle is crucial for optimal driveline performance. By troubleshooting and addressing any issues promptly, you can ensure a smooth and efficient driveline operation, prolong the lifespan of your driveline components, and enjoy a comfortable driving experience.

Conclusion

In conclusion, ensuring the correct pinion angle is vital for smooth and efficient driveline operation. By following the steps outlined in this guide on “how to find pinion angle,” you can accurately measure and adjust the angle to the manufacturer’s specifications. This alignment and periodic inspection of the pinion angle help maintain optimal driveline performance, preventing issues such as vibrations, premature driveline wear, and damaged U-joints. Remember, if you encounter persistent issues or have complex cases, it’s always wise to consult a professional or utilize advanced tools for precision. Take the necessary steps to maintain the correct pinion angle, and enjoy a driveline that operates flawlessly and reliably.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.