A bent radiator support can cause significant issues for your vehicle, impacting the cooling system’s efficiency and potentially leading to further damage if left unaddressed. Fortunately, fixing a bent radiator support is a manageable task with the right tools and techniques.

In this article, we’ll explore various methods for how to fix a bent radiator support, from basic approaches that can be done at home to more advanced procedures that may require professional assistance.

We’ll discuss the importance of addressing the issue promptly to prevent further damage to your car’s cooling system and structural integrity. Whether you’re dealing with a minor bend or more severe damage, understanding how to properly repair a bent radiator support is essential for maintaining the performance and safety of your vehicle.

Importance of Addressing Bent Radiator Support

Neglecting a bent radiator support can lead to a cascade of automotive problems, drastically affecting your vehicle’s performance and overall safety. The radiator support, serving as the backbone for holding the radiator in place, plays a crucial role in the vehicle’s cooling system.

A bent support can impede the radiator’s ability to cool the engine efficiently, leading to overheating issues which can cause severe engine damage if unchecked.

Furthermore, the structural integrity of your vehicle’s front end is compromised, putting additional components at risk during driving or in the event of an accident. Addressing a bent radiator support promptly not only prevents further damage to your vehicle but also ensures the safety of its occupants by maintaining the car’s structural reliability.

Common Causes of Bent Radiator Supports

Bent radiator supports can result from a variety of incidents, the most common being front-end collisions. Even minor fender benders, if hit at just the right angle, can exert enough force to warp the support structure. Apart from accidents, everyday driving conditions, such as navigating potholes or hitting road debris, can also lead to bending.

Over time, these seemingly minor impacts can accumulate, compromising the radiator support. Additionally, rust and corrosion are significant contributors, particularly in older vehicles or those frequently exposed to moist or salt-rich environments.

This corrosion weakens the metal, making it more susceptible to bending from routine stresses or impacts. Understanding these common causes can help drivers take preventative measures to protect their radiator supports from damage.

Role and Function of the Radiator Support in a Vehicle

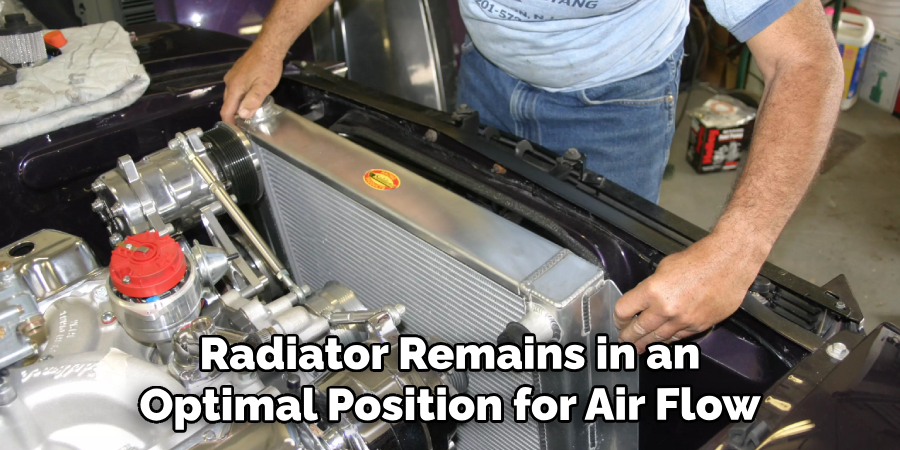

The radiator support plays a pivotal role in the overall functionality and safety of a vehicle. Acting as a structural frame located at the front of the engine compartment, it is specifically designed to secure the radiator in place, along with other critical cooling components such as the condenser.

This support structure ensures that the radiator remains in an optimal position for air flow, crucial for maintaining the engine’s temperature within safe operating limits. In addition to its primary role in engine cooling, the radiator support contributes to the vehicle’s structural integrity, especially in frontal impacts.

It helps distribute and absorb shock, protecting the engine and passengers by lessening the force of collisions. Therefore, the radiator support not only aids in efficient engine cooling but also plays an integral part in the vehicle’s safety features, underscoring the necessity of maintaining it in good condition.

Common Causes of Bent Radiator Supports

The role and function of the radiator support in a vehicle have been previously described, highlighting its significance in securing the radiator and other cooling components, maintaining engine temperature, and contributing to the vehicle’s structural integrity and safety.

Keeping the radiator support in optimal condition is essential for ensuring these systems work effectively together, safeguarding the engine’s performance and the occupants’ safety. Regular inspection and maintenance are crucial steps in preventing potential issues and extending the life of your vehicle.

Impact of a Bent Radiator Support on Vehicle Performance

A bent radiator support can significantly impair vehicle performance, particularly in terms of cooling and structural stability. When the support is deformed, it can disrupt the radiator’s placement and stability, leading to inadequate cooling of the engine. This inefficiency in heat dissipation often results in the engine operating at higher temperatures than intended.

Over time, running the engine at these elevated temperatures can decrease its performance, increase fuel consumption, and potentially lead to engine overheating. Engine overheating is a serious issue that can cause engine components to fail, leading to costly repairs.

Additionally, a compromised radiator support structure can alter the alignment and positioning of other critical components in the front end, affecting the vehicle’s handling, aerodynamics, and even its safety in the event of a collision. Addressing a bent radiator support promptly is crucial to maintaining optimal vehicle performance and preventing further damage.

10 Methods How to Fix a Bent Radiator Support

Method 1: Assess the Damage

Before attempting any repairs, thoroughly assess the extent of the damage to the radiator support. Inspect for any cracks, dents, or misalignments that may have occurred as a result of the impact. Determine if the radiator support can be straightened or if it needs to be replaced entirely.

It is important to also check for any damage to the surrounding components, such as the radiator, condenser, and fan. These may have been affected by the impact and will need to be repaired or replaced as well.

Once you have a clear understanding of the damage, you can determine the best course of action for repairs. This may involve using specialized tools or seeking professional assistance.

Method 2: Support the Vehicle

Ensure the vehicle is securely supported on jack stands or a lift to provide adequate clearance for working underneath. Safety should always be the top priority when performing repairs on a vehicle. Never work underneath a vehicle that is only supported by a jack.

Additional precautions should be taken when working on a lifted vehicle. Use wheel chocks to prevent the vehicle from rolling or shifting while elevated. It is also important to make sure the lift arms and supports are positioned correctly and securely before beginning any work.

Once the vehicle is properly supported, it is important to follow proper safety procedures when working underneath. This includes wearing a sturdy pair of gloves, safety glasses, and closed-toe shoes to protect against any potential hazards.

It is also important to have the necessary tools and equipment ready before starting any repairs. This will help prevent any unnecessary delays or accidents caused by scrambling for tools while in the middle of a repair.

Method 3: Remove the Radiator and Other Components

If necessary, remove the radiator, fan, and any other components attached to the radiator support. This will provide better access to the damaged area and prevent accidental damage to these components during the repair process.

To remove the radiator, first drain all the coolant from the system by opening the drain valve at the bottom of the radiator. Then, disconnect any hoses or electrical connections attached to the radiator. Once these are disconnected, use a wrench or socket set to loosen and remove any bolts securing the radiator in place.

Next, remove any additional components attached to the radiator support such as the fan, shroud, or air conditioning condenser. Keep track of all bolts and hardware removed during this process to ensure they are reinstalled correctly.

Once these components are removed, you will have better access to the damaged area of the radiator support. This method is often used for more extensive damage that cannot be easily accessed with other methods.

Method 4: Use a Hydraulic Jack and Wood Block

For minor bends in the radiator support, you can use a hydraulic jack and a wooden block to gently push the metal back into place. Position the jack under the bent section of the support and place the wood block between the jack and the support to distribute the pressure evenly.

Slowly pump the jack to apply pressure until the radiator support is straightened. This method may require more time and effort compared to the previous methods, but it is a safer option as it avoids using excessive force on the support.

It is important to note that these methods are only suitable for minor bends in the radiator support.

If the damage is extensive or if there are any cracks or tears in the metal, it is best to replace the support altogether. Also, keep in mind that these methods may not work for modern vehicles with aluminum or plastic radiator supports. In such cases, it is best to consult a professional mechanic for repairs.

Another important aspect to consider when straightening a bent radiator support is the alignment of other components. A minor bend in the support can cause misalignment in other parts of the vehicle, such as the hood or fenders.

After straightening the support, it is recommended to check and adjust the alignment of these components to ensure proper functioning and safety.

Method 5: Heat and Bend Technique

For more stubborn bends, you can use a heat source such as a torch to heat the metal before bending it back into shape. Be cautious when using this method, as excessive heat can weaken the metal. Once heated, use a hammer or pry bar to carefully bend the radiator support back into its original position. After completing the bend, allow the metal to cool before testing its strength.

It may be helpful to use a heat-resistant glove or pliers when handling heated metal. Additionally, you can also use a heat gun if you do not have access to a torch. This method should only be used as a last resort, as excessive heat can cause damage and compromise the structural integrity of the radiator support.

It is important to note that this method should only be used if the bend is not too severe and can still be easily manipulated. If the bend is too severe, it may require professional assistance or replacement of the radiator support altogether.

Method 6: Welding and Reinforcement

If the radiator support is severely bent or damaged, welding may be necessary to reinforce the structure. Weld additional metal plates or braces to strengthen the damaged area and ensure proper alignment. This method may require welding skills and equipment, so it’s best left to experienced professionals.

Welding is a process of joining two pieces of metal together by heating them to a melting point and then using pressure or filler material to create a bond. It can be used in various applications, including automotive repairs such as reinforcing damaged radiator supports.

Before attempting any welding on the radiator support, it’s important to clean the area thoroughly to ensure proper adhesion. Any debris, rust, or paint must be removed before welding as it can compromise the strength and integrity of the weld.

Method 7: Replacement of Radiator Support

In cases of extensive damage where straightening or welding is not feasible, replacing the entire radiator support may be the best option. OEM or aftermarket replacement radiator supports are available for most vehicle makes and models. Follow manufacturer guidelines and ensure proper alignment during installation to avoid further issues.

Replacement of the radiator support typically involves removing the grille, headlights, and front bumper to gain access. Once these components are removed, detach any remaining bolts or brackets securing the old radiator support to the frame and remove it from the vehicle.

Before installing the new radiator support, inspect and clean any surrounding areas that may have been damaged in the accident. This will ensure a smooth and secure fit for the new support.

When installing the replacement radiator support, follow manufacturer guidelines and use proper tools to align and secure it in place. Once installed, reattach all removed components such as the grille, headlights, and front bumper.

Method 8: Professional Frame Straightening

For severe damage that affects the vehicle’s frame or structural integrity, professional frame straightening services may be required. Specialized equipment and expertise are necessary to accurately assess and repair bent frames and radiator supports. Consult with a reputable auto body shop or collision repair center for assistance.

Frame straightening typically involves the use of a hydraulic frame machine that uses strong pulling and pushing forces to reshape the damaged areas. The process requires precise measurements and careful adjustments, as even small errors can affect the vehicle’s handling and safety.

In addition to straightening the frame itself, other components such as suspension parts and steering components may also need to be replaced or realigned. This is to ensure that the vehicle’s alignment and handling are not compromised after the frame has been straightened.

It is important to note that frame straightening can be a time-consuming and costly process, depending on the severity of the damage and the necessary repairs. However, it is crucial for ensuring the safety and structural integrity of your vehicle in the long run.

Method 9: Reinforcement Plates

Installing reinforcement plates or braces can help prevent future damage to the radiator support by strengthening weak or vulnerable areas. These plates are typically welded or bolted onto the existing support structure and provide added durability and support. They can also help distribute impact forces more evenly in the event of a collision, reducing the risk of severe damage.

Reinforcement plates are usually made from strong materials such as steel or aluminum and come in various shapes and sizes to fit different types of vehicles. They can be installed by a professional mechanic or with some basic welding and drilling skills, but it is important to follow the manufacturer’s instructions carefully.

In addition to providing extra support, reinforcement plates can also improve the overall appearance of the radiator support. They can be painted or powder-coated to match the color of your vehicle and give it a more customized look. Some aftermarket reinforcement plates even come with designs or logos for added personalization.

Method 10: Regular Maintenance and Inspection

Once the radiator support is repaired or replaced, it’s essential to perform regular maintenance and inspections to ensure it remains in good condition. Check for signs of rust, corrosion, or damage, especially in areas prone to impact or stress. Promptly address any issues to prevent further damage and ensure the proper function of the cooling system.

Regularly clean the radiator and surrounding components to prevent buildup of dirt, debris, or other contaminants. Clogged or dirty radiators can hinder airflow and reduce cooling efficiency, leading to potential overheating issues.

In addition to visual inspections, it’s also important to check the coolant levels and quality regularly. Low coolant levels can lead to overheating and potential engine damage, while contaminated coolant can cause corrosion and other issues within the cooling system.

Conclusion

In conclusion, addressing a bent radiator support is crucial for maintaining the structural integrity and functionality of a vehicle’s cooling system. By understanding the components of the radiator support and assessing the extent of the damage, individuals can effectively follow the outlined steps to repair the bent support.

Prioritizing safety precautions and proper preparation ensures a successful repair process. Through the use of hydraulic jacks, pullers, and welding techniques, individuals can straighten and reinforce the radiator support to its original form. Thanks for reading, and we hope this has given you some inspiration on how to fix a bent radiator support!