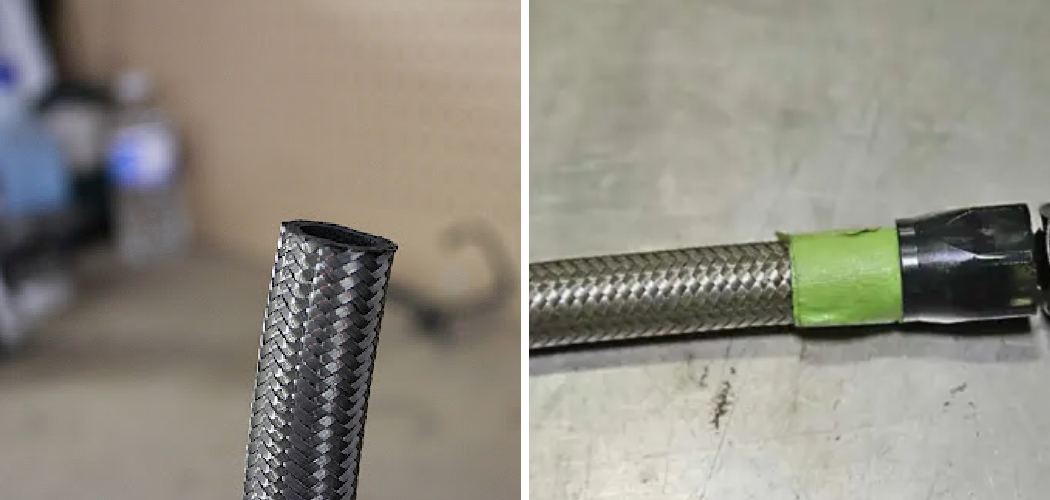

Cutting steel braided hose is a task that requires both precision and the right tools to ensure a clean cut without damaging the hose.

Whether you’re working on automotive projects, plumbing, or any other application that utilizes steel braided hoses, following the correct procedure is crucial for both the performance and the longevity of the hose.

In this guide on how to cut steel braided hose, we will walk you through the steps necessary to cut steel braided hose safely and efficiently, ensuring a professional and reliable outcome for your project.

What You Will Need

Before we dive into the cutting process, let’s first go over the tools and materials you will need. These include:

Steel Braided Hose:

This is the main material that you will be cutting. Make sure to have the appropriate size and length for your project.

Tape Measure:

You will need a tape measure to accurately measure the length of the hose needed for your project.

Marker or Chalk:

These tools are necessary to mark the exact location where you want to cut the hose.

Vice Grips:

Vice grips or locking pliers are essential for holding the hose in place while cutting.

Hacksaw or Angle Grinder:

These are the two most commonly used tools for cutting steel braided hoses. The choice between them depends on personal preference and availability, but both can give precise cuts when used correctly.

8 Step-by-step Guides on How to Cut Steel Braided Hose

Step 1: Prepare the Hose

Begin by laying out the steel braided hose on a flat, stable surface. Use the tape measure to determine the exact length of hose you need for your project.

Mark the spot where you want to make your cut with a marker or chalk, ensuring that the marking is clear and precise. This initial preparation is critical for achieving an accurate cut and preventing any mistakes that could affect the hose’s performance.

Secure the hose in place with vice grips or locking pliers near the marked area, ensuring it is held firmly to avoid any movement during the cutting process. This stability is essential for a clean, precise cut.

Step 2: Choose Your Cutting Tool

Selecting the right cutting tool for your steel braided hose is pivotal to achieving a clean and precise cut. You have two main options: a hacksaw or an angle grinder.

Hacksaw:

A hacksaw is a manual tool that offers excellent control for detailed cuts. It is generally slower than an angle grinder but provides a high degree of accuracy. Ensure that you use a fine-toothed blade designed for cutting metal to avoid fraying the steel braid.

Angle Grinder:

An angle grinder is a power tool that can significantly speed up the cutting process. Equipped with a cutting wheel suitable for metal, it can make quick work of the hose. While less physically demanding than a hacksaw, it requires a steady hand and careful operation to avoid damaging the hose’s internal lining.

Consider the tools you have on hand, your comfort level with each, and the specific requirements of your project before making a decision.

Step 3: Put on Protective Gear

Safety should always be a priority when cutting steel braided hoses. Before you begin the cutting process, put on the appropriate protective gear to safeguard yourself from potential injuries.

This includes wearing safety glasses to protect your eyes from metal fragments and sparks and gloves to shield your hands from sharp edges and hot surfaces. If you’re using an angle grinder, consider wearing hearing protection due to the noise generated by the tool.

Ensuring you have the right protective equipment will help you carry out the cutting process safely and efficiently, preventing accidents and injuries.

Step 4: Cut the Hose

Now, it’s time to make the cut. Using your chosen cutting tool, carefully start cutting at the marked spot on the hose. If using a hacksaw, apply even pressure and use long, smooth strokes for a clean cut. For an angle grinder, gently guide the cutting wheel through the hose while maintaining control of both hands and avoiding any sudden movements or excessive force.

Continue cutting until you reach the other side of the hose. Take your time and be patient to ensure a precise cut without damaging the steel braid or internal lining.

Step 5: Check for Frayed Ends

After successfully cutting through the hose, it’s essential to inspect the cut ends for any fraying.

Frayed steel braiding can compromise the integrity of the hose and potentially lead to leaks or other performance issues. Carefully examine the edges of the cut to ensure that the steel braids are lying flat and are not splaying out.

If you notice any fraying, you can smooth out the edges using a metal file or sandpaper.

Be gentle during this process to avoid further damage to the hose. Ensuring the cut ends are clean and free of fraying is crucial for the hose to fit correctly and function as intended in your project.

Step 6: Remove Vice Grips

Once you have completed the cut and checked for any frayed ends, the next step is to remove the vice grips or locking pliers from the hose.

Carefully release the vice grips, ensuring that the hose remains steady while you do so to prevent any sudden movements that could affect the freshly cut end.

Removing the vice grips gently will help maintain the integrity of your precise cut and keep the steel braiding intact. Once the vice grips are removed, inspect the hose once more to ensure it has not shifted or sustained any damage during the process.

This step is essential for maintaining the quality and functionality of the hose and preparing it for the next phase of your project.

Step 7: Inspect the Cut

Before using the hose, it’s crucial to inspect the cut for any imperfections or issues. Check that both ends of the cut are smooth and even, with no fraying or jagged edges. If you notice any damage or inconsistencies, repeat the cutting process until you achieve a clean, precise cut.

Ensuring that your cuts are perfect is vital to guarantee a secure fit and optimal performance of your steel braided hose in your project.

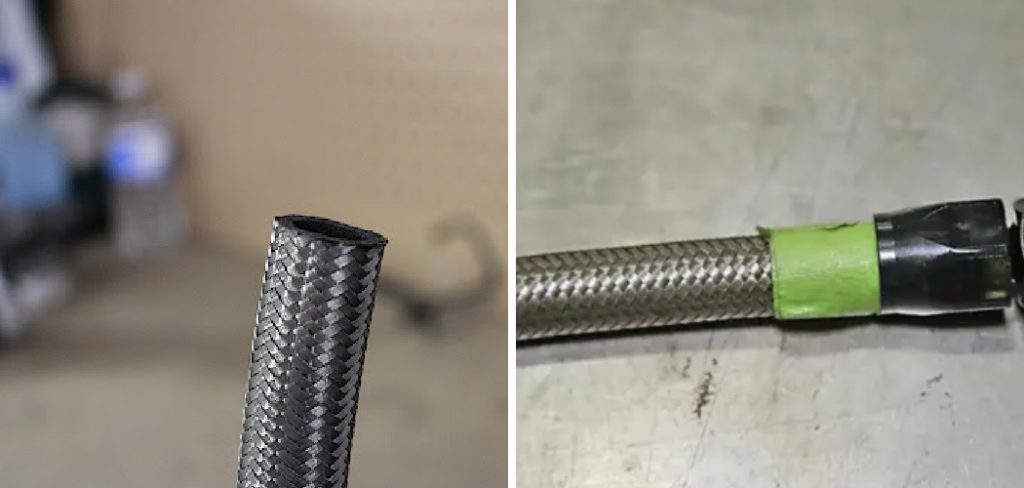

Step 8: Install Hose Fittings (Optional)

If your project requires hose fittings, this is the time to install them. Begin by selecting the appropriate fittings for your steel braided hose, ensuring they are compatible in terms of size and type.

Hose fittings are essential for connecting the hose to other components securely, and they can vary from simple clamps to more complex connectors, depending on your needs.

Before installing the fittings, make sure the cut end of the hose is clean and free from any debris or loose strands. Slide the fitting over the cut end, making sure it is properly oriented and aligned.

If using a clamp-style fitting, tighten it securely around the hose using a screwdriver or a wrench, depending on the design of the fitting. For more complex connectors, follow the manufacturer’s instructions carefully to ensure a proper fit.

Once the fitting is installed, give a gentle tug on the hose to verify that the fitting is secure and won’t come loose under pressure. Properly installed fittings are critical for ensuring that your hose maintains its integrity and performance in the system, providing a reliable connection that prevents leaks.

After installation, double-check the fitting and hose assembly to ensure everything is securely in place and ready for use. This optional step can significantly contribute to the efficiency and durability of your project by ensuring a strong and dependable connection.

Troubleshooting and Tips for Successful Cutting

Common Issues and Solutions

Even with careful preparation, you may encounter some challenges when cutting steel braided hose. Here are a few common issues and their solutions:

- Fraying: If you notice significant fraying of the steel braiding, check your cutting tool’s sharpness and the cutting technique. Ensure you are using a proper metal cutting blade or wheel, and make smooth, even strokes. Wrapping the area with electrical tape before cutting can also help minimize fraying.

- Uneven Cuts: An uneven cut can affect the hose’s performance and ability to connect with fittings. To address this, double-check your measurements and marked lines before making the cut. Using a guide or miter box can help provide a straighter cut. Ensure the hose is held securely in place with vice grips to prevent movement during cutting.

- Difficulty Cutting Through If your tool struggles to cut through the hose, inspect the blade or cutting wheel for wear and replace it if necessary. Applying too much or too little force can also cause difficulty. Aim for steady pressure and use the full length of the cutting surface to maximize efficiency.

- Damaging the Internal Lining: Precision is key to avoiding damage to the hose’s internal lining. When using an angle grinder, maintain a controlled, steady hand to avoid cutting too deep. If you’re unsure, practice on a spare piece of hose to get a feel for the tool’s handling.

Tips for a Clean Cut

Use Quality Tools:

Investing in high-quality cutting tools will make the cutting process smoother and more precise. Ensure that blades or cutting wheels are specifically designed for metal cutting.

Mark Clearly:

Use a fine marker or specialized tape to mark your cutting line clearly. Double-check measurements to ensure accuracy.

Secure the Hose:

Always use vice grips or clamps to hold the hose steady. This prevents the hose from moving during cutting, resulting in a cleaner cut.

Slow and Steady:

Take your time and avoid rushing the cutting process. Patience and controlled movements yield the best results.

Inspect Frequently:

Periodically check the state of your cutting tool and the hose during the process. This helps catch any potential issues early on, allowing for quicker corrections.

By following these troubleshooting tips on how to cut steel braided hose and best practices, you can achieve a precise, clean cut on your steel braided hose, ensuring optimal performance and durability for your project.

Safety Considerations and Environmental Impact

When working with steel braided hoses, it is crucial to prioritize safety to prevent accidents and ensure a smooth project execution. Here are some key safety tips to keep in mind:

Wear Protective Gear:

Always wear safety goggles to protect your eyes from metal shards and particles, and use gloves to shield your hands from sharp edges. Long sleeves and pants made from durable material can further reduce the risk of injury.

Ensure Proper Ventilation:

If you are working with cutting tools that produce fumes or dust, make sure your workspace is well-ventilated. This helps avoid inhaling potentially harmful particles.

Secure Your Workspace:

Keep your work area organized and free from clutter. Ensuring a clean workspace can prevent trips, falls, and other accidents.

Handle Tools Correctly:

Familiarize yourself with the operation of your cutting tools. Knowing how to properly start, use, and maintain these tools will minimize the risk of injury.

First Aid Preparedness:

Have a first aid kit readily available in case of any minor accidents. Knowing basic first aid procedures can be beneficial in handling unforeseen injuries quickly and effectively.

Environmental Impact

Considering the environmental impact of your project is equally important. Properly managing waste and reducing your environmental footprint can make your project more sustainable:

Proper Disposal:

Dispose of all waste materials, such as metal offcuts and used blades, according to local regulations. Recycling these materials when possible can reduce environmental impact.

Minimize Waste:

Plan your cuts carefully to avoid unnecessary waste. Efficient use of materials not only saves resources but also reduces the amount of waste generated.

Use Eco-Friendly Products:

Opt for eco-friendly tools and materials where possible. Products made from recycled materials or those that have minimal environmental impact can contribute to a more sustainable project.

Energy Efficiency:

Use energy-efficient tools and equipment to minimize electricity consumption. This not only helps the environment but can also reduce energy costs.

Chemical Handling:

If your project involves the use of lubricants or solvents, choose non-toxic, biodegradable options to minimize harmful effects on the environment.

By integrating these safety considerations and environmental practices into your project, you can ensure not only a successful outcome but also contribute positively to the well-being of both your immediate surroundings and the broader environment.

Frequently Asked Questions

Q: Can I Use a Regular Hacksaw to Cut Through a Steel Braided Hose?

A: Yes, you can. However, it may be more physically demanding and time-consuming than using an angle grinder or other power tools specifically designed for cutting metal. Make sure to use a new, sharp hacksaw blade and take your time to achieve a clean, precise cut.

Q: What Is the Best Way to Cut Through Steel Braided Hose?

A: The best way will depend on your comfort level, the tools available, and project requirements. Using an angle grinder or similar power tool is typically faster and more efficient than using a hacksaw.

However, if you’re more comfortable with a hacksaw or have a smaller hose to cut, it may be the preferred method for you.

Q: Do I Need Protective Gear When Cutting Steel-braided Hose?

A: Yes, protective gear is essential when cutting steel braided hose. Safety glasses and gloves are necessary to protect yourself from potential hazards such as flying debris or sharp edges. If using power tools, make sure to follow all safety precautions recommended by the manufacturer.

Q: Why Is It Important to Check for Frayed Ends After Cutting the Hose?

A: Frayed ends can compromise the integrity of the hose and potentially lead to leaks or performance issues.

Ensuring that there are no frayed steel braids is crucial for a secure fit and optimal functionality of the hose in your project. Taking the time to inspect and smooth out any frayed ends will help prevent potential problems down the line.

Q: Can I Use Steel Braided Hose for Any Type of Project?

A: It depends on the specifications and intended use of the hose. While steel braided hoses are generally strong and durable, they may not be suitable for certain types of projects due to their size, length, or specific pressure and temperature requirements.

Make sure to consult with a professional or carefully read product labels to determine if a steel braided hose is appropriate for your project.

Conclusion

Cutting steel braided hose may seem like a daunting task, but with the right tools and techniques, it can be done safely and precisely. Remember to always put safety first by wearing protective gear and carefully choosing the cutting tool that works best for your project.

Take your time during the cutting process to ensure a clean cut without frayed ends or jagged edges, and always inspect the hose for any imperfections before using it. With these steps on how to cut steel braided hose in mind, you can confidently tackle your project involving steel braided hoses and achieve professional results.

Therefore, it is essential to follow all safety precautions and use the right tools to ensure a successful outcome for your project. Happy cutting!