Combining concrete with metal in construction projects offers significant benefits, including enhanced strength and durability. This powerful combination finds applications in various fields, such as reinforced concrete structures, decorative projects, and structural elements. However, bonding concrete to smooth or untreated metal surfaces presents challenges due to the differences in their properties. To achieve a strong and long-lasting bond, proper surface preparation is crucial. This ensures optimal adhesion between the two materials, maximizing the structural integrity and longevity of the concrete-metal connection.

In this guide, we will explore how to add concrete to metal, providing you with the knowledge and insights to tackle this unique bonding process. Whether you’re working on a small DIY project or a large-scale construction endeavor, understanding the intricacies of concrete-metal bonding will empower you to create durable and reliable structures. Let’s dive into the world of combining concrete with metal and unlock the potential of this robust construction technique.

Tools and Materials Needed

To successfully bond concrete to metal, you’ll need the following tools and materials:

Tools

- Wire brush, sandpaper, or grinder for surface preparation: These tools help remove dirt, grease, and rust from the metal surface, ensuring proper concrete adhesion.

- Drill and screws for anchoring (if required): In some cases, you may need to anchor the metal piece to provide additional stability and support.

- Concrete mixer or mixing tools for concrete preparation: Depending on the scope of your project, you’ll need either a concrete mixer or appropriate tools for manually mixing the concrete.

Materials

- Metal piece: Choose a suitable metal piece for your project, such as a steel frame, rebar, or sheet metal. Ensure that the metal is compatible with concrete and can withstand the intended application.

- Concrete mix suitable for the application: Select the right type of concrete mix based on your project’s specific requirements, such as strength, durability, and weather resistance.

- Adhesive agents, bonding primers, or epoxy (optional): Depending on the bonding requirements and specific project needs, you may consider using adhesive agents, bonding primers, or epoxy to enhance the bond between the concrete and metal.

Having these tools and materials at hand will ensure that you have everything you need to carry out the concrete-metal bonding process effectively and efficiently.

Preparing the Metal Surface

Before applying concrete to a metal surface, it’s essential to ensure that the surface is properly prepared. This preparation process involves cleaning and roughening the surface to promote better adhesion between the concrete and the metal.

Cleaning the Surface

To prepare the metal surface, start by removing any dirt, grease, or rust that may be present. Use a degreaser and a wire brush to scrub the surface thoroughly. It’s important to have a clean surface as dirt and grease can hinder the bonding process. By removing these contaminants, you create a clean and smooth surface that allows for proper adhesion of the concrete.

Roughening the Metal

To enhance the bond between the concrete and the metal, it’s beneficial to create a textured surface. This can be achieved through techniques such as sanding or grinding. By roughening the metal, you provide more surface area for the concrete to adhere to, increasing the strength of the bond. Additionally, you can consider using perforations or anchors strategically placed on the metal surface to provide additional grip for the concrete. These perforations or anchors create a mechanical bond between the concrete and the metal, further enhancing the overall bond strength.

By effectively cleaning and roughening the metal surface, you ensure optimal adhesion between the concrete and the metal, setting the stage for a strong and durable bond.

Preparing the Concrete Mix

Preparing the concrete mix correctly is crucial for ensuring a strong and durable bond between the metal and concrete. Choosing the right mix and following proper mixing procedures are essential for optimal consistency and strength.

Choosing the Right Mix:

Selecting the appropriate concrete mix is vital, as different applications require specific properties. For example, quick-set concrete may be suitable for projects that require rapid curing, while standard concrete is commonly used for general applications. Decorative concrete mixes offer aesthetic options for projects that require a visually appealing finish. Consider the requirements of your project and consult with concrete experts to determine the most suitable mix.

Mixing Process:

Achieving a lump-free and workable consistency is crucial for ensuring the concrete adheres well to the metal surface. Follow these tips for an effective mixing process:

- Proper Proportions: Follow the recommended mixing ratios provided by the concrete manufacturer. This ensures the right balance of ingredients for optimal strength and workability.

- Water Quantity: Gradually add water to the mix while continuously mixing until you achieve a consistency that is not too dry or too wet. The concrete should be easy to work with but not overly fluid.

- Mixing Equipment: Use a reliable concrete mixer or mixing tools to ensure a thorough and consistent blend. Avoid mixing in small batches, as this can lead to inconsistencies in the mix.

- Mixing Duration: Mix the concrete for the recommended duration, typically a few minutes, to ensure uniform distribution of the ingredients.

- Scraping the Sides: Periodically scrape the sides of the mixing container to incorporate any unmixed materials into the mix.

By carefully choosing the right concrete mix and following proper mixing procedures, you can ensure a well-prepared concrete mixture that is ready for application and will adhere effectively to the metal surface, strengthening the bond between the two materials.

How to Add Concrete to Metal: Applying Concrete to Metal

Proper application techniques are essential to ensure a strong bond between concrete and metal. This process involves using adhesives or primers to enhance the grip between the two materials, pouring or placing the concrete, and smoothing and leveling the surface.

Using Adhesives or Primers

One effective method to enhance the bond between concrete and metal is to apply a bonding primer or epoxy adhesive to the metal surface. These products create a strong adhesive layer that improves the concrete’s adhesion. Following the manufacturer’s instructions while applying the primer or adhesive is important. Additionally, allow the primer or adhesive to dry partially before pouring or placing the concrete.

Pouring or Placing the Concrete

When applying concrete to a metal surface, it is crucial to pour or place the concrete evenly, ensuring that it fills any gaps and adheres to anchors or perforations in the metal. Start by pouring the concrete onto the surface and spread it evenly using a trowel or other suitable tools. Work the concrete into corners and edges to ensure complete coverage. Pay close attention to any areas that require extra reinforcement or where the concrete needs to bond tightly with the metal. Additionally, make sure the concrete is at the recommended thickness to provide adequate strength and durability.

Smoothing and Leveling

After pouring or placing the concrete, use tools like trowels to level the surface and create a smooth finish. Work the trowel in a back-and-forth motion, ensuring that the concrete is evenly spread and any air pockets are eliminated. Smooth and level the concrete to achieve the desired surface texture and appearance. Don’t overwork the concrete, as this can negatively affect the final finish.

By following these steps and techniques for applying concrete to metal surfaces, you can achieve a strong bond that ensures the structure’s longevity and durability. Proper application techniques are crucial for creating a reliable and secure connection between the concrete and the metal surface.

Curing the Concrete

Properly curing the concrete is essential for achieving maximum strength and durability. The curing process involves maintaining the moisture content and protecting the surface from external factors during the initial stages of concrete hardening. Here are some key considerations for an effective curing process:

Proper Curing Process

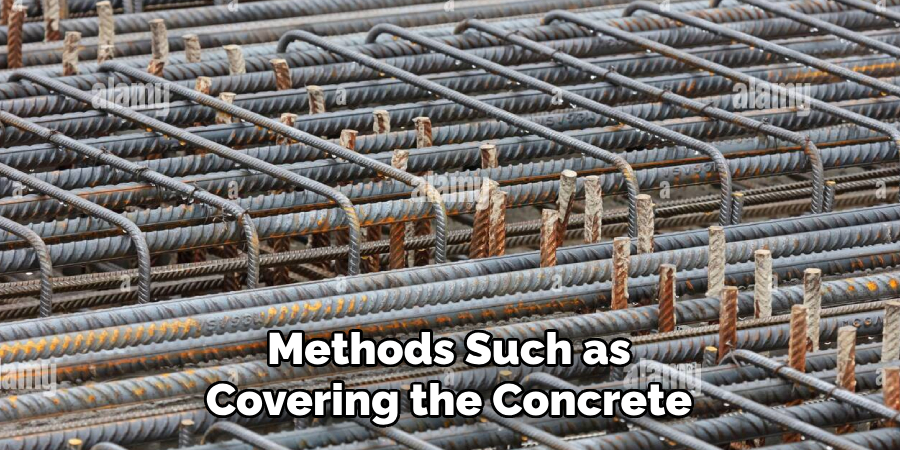

To ensure optimal curing, allowing the concrete to cure slowly is crucial. This can be achieved by keeping the surface moist for an extended period. Methods such as covering the concrete with plastic sheets, applying a curing compound, or using wet burlap can help retain moisture. Additionally, protecting the concrete from direct sunlight is important, as it can cause rapid moisture evaporation and result in surface cracks.

Common Mistakes to Avoid

One common mistake is rushing the curing process. Resist the temptation to accelerate drying or expedite the project timeline. Rapid drying can lead to a weaker and less durable concrete structure. Another mistake is exposing the curing setup to vibrations or excessive movement, which can disrupt the curing process and weaken the bond between the concrete and the metal surface. Taking care to avoid these mistakes will ensure a properly cured concrete-metal connection, enhancing the longevity and performance of the structure.

Testing the Bond and Finishing Touches

To ensure a strong and reliable concrete-metal connection, it is essential to test the bond and add finishing touches to enhance the structure’s aesthetics and longevity.

Testing Adhesion

After the curing process, inspecting the bond between the concrete and metal surfaces is crucial. Lightly tapping or applying gentle pressure along the connection can help identify any areas where the concrete may not have adhered securely. If any loose or weak areas are detected, additional measures should be taken to reinforce the bond and ensure structural integrity.

Applying Finishes

Once the bond has been confirmed, it’s time to apply finishes to the concrete-metal surface. Depending on the specific project requirements, this may involve painting the surface, sealing it with protective coatings, or adding decorative touches. The choice of finishes should consider the desired appearance and the environmental conditions the structure will be exposed to. Properly applied finishes not only enhance the visual appeal but also provide an additional layer of protection against rust, moisture penetration, and other environmental factors that could compromise the durability of the concrete-metal connection.

By testing the adhesion and applying suitable finishes, you can ensure the concrete-metal connection is secure and well-protected, contributing to the structure’s longevity and performance.

Tips for Long-Term Durability

To ensure the long-term durability of the concrete-metal connection, consider the following tips:

- Regular Inspection: Conduct routine inspections to check for any cracks or separation between the concrete and metal. Early detection allows for prompt repairs and reinforces the structural integrity.

- Reapply Protective Coatings: Periodically reapply protective coatings to the concrete-metal surface to prevent rust and moisture penetration. This helps preserve the connection’s durability and extends its lifespan.

- Environmental Considerations: Avoid exposing the concrete-metal connection to harsh chemicals or extreme weather conditions that can accelerate deterioration. To mitigate potential damage, take appropriate measures, such as providing proper drainage and using corrosion-resistant materials.

Proper maintenance and attention to these tips will contribute to the long-term durability and performance of the concrete-metal connection, ensuring its resilience against environmental factors and maintaining its structural integrity over time.

Conclusion

In conclusion, adding concrete to metal can be a reliable and durable technique for various structural and creative projects. You can ensure long-lasting and resilient results by following the proper steps and considering important factors, such as surface preparation and curing. Regular inspections, reapplication of protective coatings, and careful environmental considerations are essential for preserving the connection’s integrity over time.

Whether it’s for reinforcing structures or creating unique designs, the concrete-to-metal technique offers versatility and strength. Embrace the opportunity to explore the possibilities and unleash your creativity while ensuring the longevity and durability of your projects. Start your journey with confidence and enjoy the benefits of this innovative method. Thanks for reading our post about how to add concrete to metal.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.