Breaking steel may seem like a daunting task, as it is renowned for its strength and durability. However, there are several techniques and tools available that can effectively weaken or break steel under certain conditions.

Understanding the properties of steel, such as its composition and tensile strength, is crucial for selecting the appropriate method. Whether for industrial applications or creative projects, the ability to manipulate steel opens up a world of possibilities.

This guide on how to break steel will explore various methods to break steel safely and efficiently, including mechanical, thermal, and chemical approaches, ensuring you choose the right technique for your specific needs.

Why Break Steel?

Before diving into the methods of breaking steel, it’s important to understand why one would want to do so. Breaking steel can serve various purposes, including recycling, shaping, or repairing damaged structures. It can also be used for artistic or experimental purposes.

For instance, in the manufacturing industry, breaking steel is a common practice to repurpose scrap metal and create new products. On the other hand, artists and craftsmen often break steel to incorporate it into their sculptures or designs. No matter the purpose, knowing how to break steel is an essential skill for those working with this strong material.

Needed Materials

To successfully break steel, you will need the following materials:

Steel Object:

This can be in the form of a sheet, bar, rod, or any other shape. The size and thickness of the steel will determine which method is most suitable.

Protective Gear:

Safety should always be a priority when breaking steel. Make sure to wear eye protection, gloves, and sturdy shoes to protect yourself from any potential hazards.

Tools:

The tools required will vary depending on the chosen method. This could include hammers, saws, blowtorches, or chemicals for chemical cutting.

8 Step-by-step Guidelines on How to Break Steel

Step 1: Choose the Right Method

The first step in breaking steel is selecting the appropriate method based on the specific characteristics of the steel object you intend to break. Consider the thickness, shape, and intended outcome to determine the most effective approach. Mechanical methods, such as using hammers or saws, are suitable for smaller, thinner pieces of steel.

For thicker steel, thermal methods like blowtorches offer a more efficient solution by heating and weakening the metal. Alternatively, chemical methods involving specialized cutting agents can be employed for precision work or intricate shapes. Assessing these factors will guide you in selecting a technique that ensures efficiency and safety for your project.

Step 2: Prepare the Area

Before starting, it’s important to prepare a suitable workspace. Ensure there is enough room for you to safely maneuver and that the area is well-ventilated in case of any chemical fumes or smoke from thermal methods. Remove any flammable materials, and cover nearby surfaces with protective materials.

You may also consider securing the steel object in place using clamps or a vice to prevent it from moving during the breaking process.

Step 3: Wear Protective Gear

Safety is paramount when breaking steel, so donning the appropriate protective gear is essential. Begin by wearing safety goggles to protect your eyes from flying debris or sparks that may result from mechanical or thermal methods. Heavy-duty gloves are necessary to shield your hands from sharp edges and high temperatures. Additionally, consider wearing a face mask or respirator, particularly if you’re working with chemicals that may release harmful fumes.

Steel-toed boots offer crucial protection for your feet in case of any dropped tools or steel pieces. Prioritize your safety by ensuring all protective gear fits properly and is in good condition before proceeding.

Step 4: Mark the Cutting Line

For cutting methods, use a measuring tool and a marker to mark the precise area where you want to break the steel. This step is crucial for precision work and can help guide your hand movements throughout the process.

But if you intend to break the steel by bending or crushing, marking may not be necessary. It’s always a good idea to have a clear plan and idea of how you want the steel to break before proceeding.

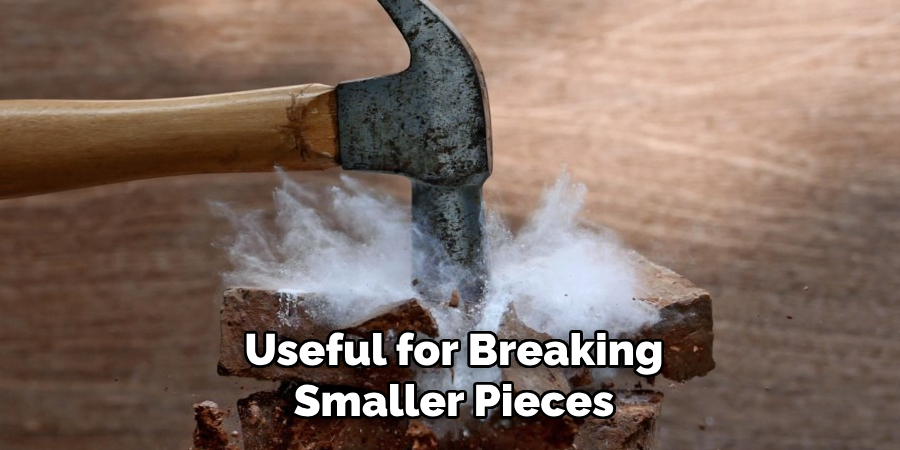

Step 5: Employ Mechanical Methods

Mechanical methods are particularly useful for breaking smaller pieces of steel or when creating specific shapes. For instance, using a hammer and chisel allows for controlled cuts along the marked line. Alternatively, power tools like saws or angle grinders with cutting discs can be used for thicker steel pieces.

When using any mechanical method, be sure to keep a firm grip on the tool and use controlled, deliberate movements to avoid accidents or injury.

Step 6: Utilize Thermal Methods

Thermal methods involve heating the steel to weaken its structure and make it easier to break. A blowtorch is often used for this purpose, as its concentrated heat can quickly soften the metal. However, caution must be taken when using this method as high temperatures can also cause burns or start fires.

Carefully direct the flame towards the marked cutting line until you see the steel turn red-hot and begin to soften. Use pliers or tongs to hold onto the heated area while applying pressure or bending it in your desired direction.

Step 7: Apply Chemical Cutting Agents

Chemical methods are commonly used in industrial settings to cut or shape steel with precision. These chemicals work by dissolving the metal and creating a clean, precise break. However, caution must be taken when handling these agents as they can be corrosive and produce toxic fumes.

Follow the manufacturer’s instructions carefully and ensure proper ventilation while working with chemical cutting agents. Wear gloves and protective eyewear to avoid contact with skin or eyes.

Step 8: Clean Up and Dispose of Materials Properly

Once you’ve successfully broken the steel, it’s important to clean up the workspace properly. Collect any debris or scraps and dispose of them safely according to local regulations.

For chemical methods on how to break steel, make sure to neutralize and clean up any spills or residue before disposing of the agent properly. Proper disposal not only ensures a safe work environment but also protects the environment from any potential harm.

Additional Tips

- Before breaking steel, consider consulting with a professional or experienced individual for guidance and advice.

- Use caution when working with any method involving intense heat or chemicals, as they can pose potential hazards if not handled properly.

- Always prioritize safety by wearing protective gear and preparing an appropriate workspace.

- Take breaks as needed to avoid fatigue, which can increase the risk of accidents.

- Follow the manufacturer’s instructions and guidelines carefully when using any specialized tools or cutting agents.

- If unsure about a particular method or technique, it’s best to seek guidance from a professional for assistance.

- Remember to properly dispose of all materials and clean up the workspace after completing the project.

- Lastly, always keep safety at the forefront of your mind when working with steel to avoid any accidents or injuries. So whether you’re breaking steel for a DIY project or in an industrial setting, following these steps and tips will ensure a safe and efficient process. Happy breaking!

Frequently Asked Questions

Q: Is It Safe to Break Steel on My Own?

A: While breaking steel can be done by individuals, it’s always recommended to have a trained professional handle the task, especially when using advanced methods or working with larger pieces of steel. Safety precautions must be taken to avoid injury or accidents.

Q: What Methods Should I Use for Breaking Thick Steel?

A: Thermal methods, such as using a blowtorch or chemical cutting agents, are more effective and efficient when breaking thicker pieces of steel. These techniques weaken the metal and make it easier to bend or cut through.

Q: Do I Need Any Special Training to Break Steel?

A: It’s highly recommended to receive proper training before attempting to break steel on your own. Knowing how to handle tools safely and understanding the properties of different types of steel can help prevent accidents and ensure successful results. Additionally, certified training may be required for industrial settings or professional jobs that involve breaking steel.

Q: Can I Reuse the Broken Pieces of Steel for Other Projects?

A: Yes, broken pieces of steel can often be repurposed or recycled for other projects. However, make sure to properly clean and inspect the pieces before using them for safety reasons. The broken pieces may also need to be cut or shaped further depending on the project.

Conclusion

Breaking steel may seem like a daunting task, but with the right materials, tools, and technique, it can be done safely and effectively. Always prioritize safety by wearing protective gear, properly securing the steel object, and following instructions carefully when using mechanical, thermal, or chemical methods. Properly disposing of materials and seeking professional training when needed are also crucial for successful outcomes.

Whether you’re a DIY enthusiast or a professional, knowing how to break steel can come in handy for various projects and tasks. So next time you encounter a piece of steel that needs breaking, don’t be afraid to give it a try!

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.