Cutting steel roof sheets requires precision and the use of proper tools to ensure clean edges and an accurate fit. Whether you’re installing a new roof or making modifications to an existing one, selecting the right cutting method is essential to maintaining the integrity of the material and achieving a professional finish. This guide will walk you through how to cut steel roof sheets effectively and safely.

Importance of Accurate Cutting

Accurate cutting plays a crucial role in ensuring the overall quality and durability of your roofing project. Properly cut steel sheets reduce the risk of improper fit, which can lead to gaps, misalignments, or compromised structural integrity. Precision in cutting also minimizes material wastage, saving both time and money. Additionally, clean and accurate cuts enhance the aesthetic appeal of the roof, contributing to a more polished and professional look. By focusing on accuracy, you can avoid potential issues, such as overlapping edges or weakened panels, ensuring a secure and weather-resistant installation.

Why Proper Cutting of Steel Roof Sheets Matters

Ensuring proper cutting of steel roof sheets is vital, not just for aesthetics but also for the long-term performance of your roofing system. Incorrectly cut sheets can lead to problems such as poor alignment, which may cause leaks, corrosion, or wind damage over time. Precise cuts maintain the protective coatings on the steel, reducing the likelihood of rust or degradation.

Furthermore, poorly cut sheets can create sharp edges that pose safety hazards during handling and installation. Proper cutting ensures that each sheet fits perfectly into its designated space, contributing to a smoother installation process and a roof that can withstand environmental stresses effectively. By prioritizing careful and accurate cutting, you enhance the durability, functionality, and safety of your roofing project.

Tools Needed for Cutting

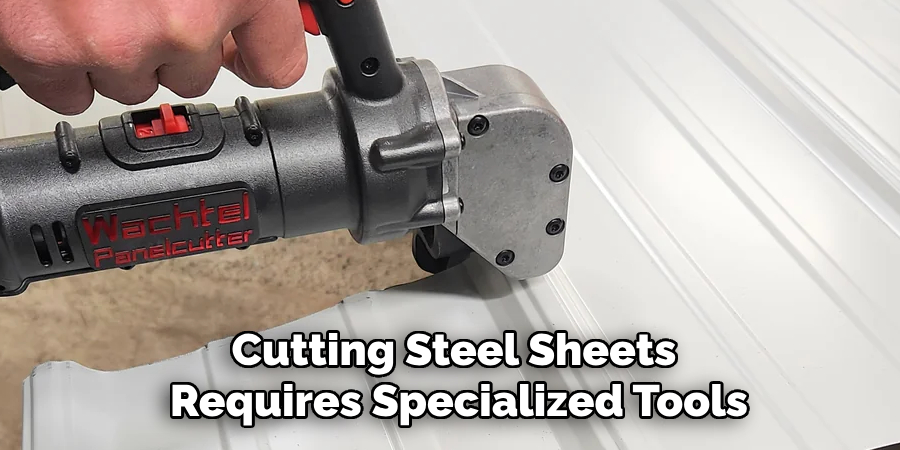

To achieve precise and clean cuts when working with steel roof sheets, having the right tools is essential. Below is a list of commonly used tools for cutting steel roof sheets:

- Tin Snips: Ideal for making straight or curved cuts, tin snips are lightweight, easy to handle, and perfect for smaller cutting tasks. They are available in left-cut, right-cut, and straight-cut variations.

- Electric Shears: A great option for faster and more efficient cutting, electric shears can handle longer cuts with ease. These tools are especially useful for thicker steel sheets.

- Angle Grinder: Equipped with a cutting disc, an angle grinder is suitable for precise, straight cuts. Ensure to use a metal-cutting blade and adhere to safety precautions, such as wearing a face shield.

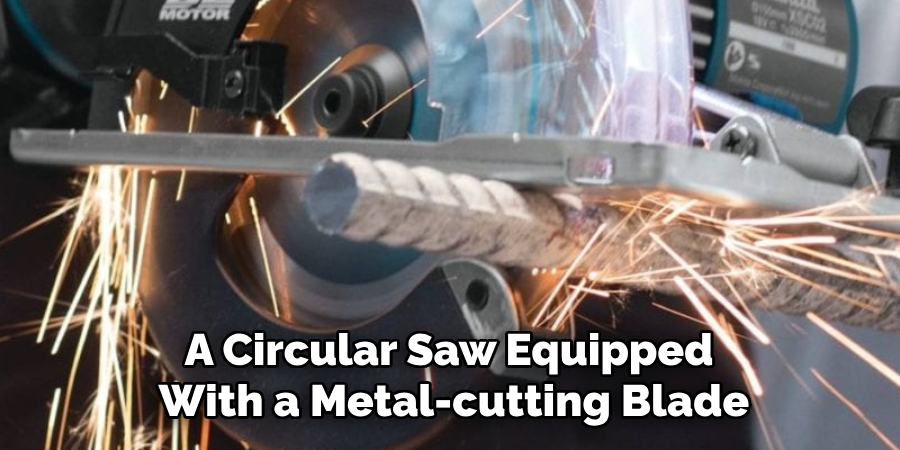

- Circular Saw: For larger projects requiring straight cuts, a circular saw with a metal-cutting blade offers high precision and speed. Always use a blade designed specifically for cutting steel.

- Nibblers: Nibblers are versatile tools that allow for intricate cutting patterns with minimal distortion to the material. They are ideal for detailed work and tight corners.

- Jigsaw: When equipped with a metal-cutting blade, a jigsaw is excellent for making curved cuts or intricate designs.

- Safety Gear: Essential for any cutting task, safety equipment such as gloves, safety glasses, and hearing protection ensures your safety while handling sharp edges and noisy tools.

Selecting the right tool depends on the type of cuts you need, the thickness of the steel, and the scope of your project. Using the appropriate tool will ensure clean cuts, preserve the integrity of the material, and make your work more efficient.

10 Methods How to Cut Steel Roof Sheets

1. Assess the Type and Thickness of Steel Sheets

Before cutting steel roof sheets, it’s essential to evaluate the material’s type and thickness. Steel sheets vary widely in thickness, ranging from lightweight corrugated panels to heavy-duty structural sheets. Thinner sheets may require simple tools like tin snips, while thicker sheets often demand more powerful equipment like an angle grinder or power saw. Knowing the material’s characteristics ensures you select the right cutting tool, preventing damage to the sheet and ensuring clean cuts.

2. Gather the Necessary Tools and Safety Equipment

Cutting steel sheets requires specialized tools and appropriate safety gear. Common tools include tin snips, aviation snips, angle grinders, power shears, and circular saws fitted with metal-cutting blades. Safety equipment is equally important; wear gloves to protect your hands from sharp edges, safety goggles to shield your eyes from flying debris, and ear protection if using loud power tools. A well-equipped workspace ensures both precision and safety during the cutting process.

3. Measure and Mark the Cutting Line

Accurate measurements and markings are critical for precise cuts. Use a tape measure to determine the exact dimensions of the section you need to cut. Mark the cutting line clearly using a pencil or a fine-tip permanent marker. For straight cuts, a long ruler or a straight edge will help maintain accuracy. If a curved cut is required, use a flexible template to guide the markings. Double-check all measurements before cutting to avoid mistakes and material wastage.

4. Secure the Steel Sheet for Stability

Stabilizing the sheet is a key step to ensure safety and accuracy. Place the steel sheet on a sturdy workbench or sawhorse, ensuring it is level and well-supported. Use clamps to secure the sheet, preventing movement during the cutting process. A stable sheet reduces the risk of jagged cuts and minimizes the chances of injury from sudden tool slips. Proper stabilization also allows for smoother and more controlled cutting.

5. Use Tin Snips for Small, Straight Cuts

Tin snips are an excellent tool for small-scale, straightforward cuts. Available in straight, left-hand, and right-hand varieties, they are ideal for cutting lightweight steel sheets. Align the snips with the marked line and apply consistent pressure as you cut, ensuring a clean and precise edge. Tin snips are particularly useful for trimming or making adjustments to pre-cut sheets. However, they may not be suitable for thicker sheets or long cuts due to limited leverage and potential for uneven edges.

6. Employ Aviation Snips for Detailed Cuts

For more intricate cuts or tight curves, aviation snips are a better choice. These tools are designed with serrated blades and a compound leverage mechanism, making them effective for detailed work on steel sheets. Choose the appropriate snip type (left, right, or straight) based on the direction of your cut. Work slowly and methodically to maintain control and achieve clean, precise edges. Aviation snips are ideal for cutting around obstacles like vents or creating custom shapes.

7. Use an Angle Grinder for Long, Straight Cuts

An angle grinder fitted with a metal-cutting disc is a powerful option for cutting long, straight lines in steel sheets. Position the grinder at the edge of the sheet and align the disc with the marked line. Apply steady pressure, guiding the grinder along the line to create a clean cut. Keep the tool at a consistent angle to avoid damaging the sheet. Wear protective gear, as this method produces sparks and metal debris. The angle grinder is particularly effective for thicker sheets or when precision over long distances is required.

8. Opt for Power Shears for Fast and Efficient Cutting

Power shears are ideal for quickly cutting through steel sheets with minimal effort. These electric or pneumatic tools feature sharp, motorized blades that make straight or curved cuts efficiently. Position the shears at the starting point of your line and guide them steadily along the marked path. Power shears are less noisy than grinders and produce cleaner cuts with fewer burrs. They are a preferred choice for professionals working on large-scale roofing projects.

9. Utilize a Circular Saw for Precision Cuts

A circular saw equipped with a metal-cutting blade is another effective tool for cutting steel roof sheets. Adjust the saw’s blade depth to match the sheet’s thickness and secure the sheet firmly to prevent movement. Start the saw and guide it slowly along the marked line, allowing the blade to do the work. Avoid forcing the saw, as this can cause jagged edges or damage the blade. This method is suitable for both straight and angled cuts, offering precision and speed for larger projects.

10. Smooth and Deburr the Edges

After cutting, steel sheets often have sharp or jagged edges that can pose safety hazards. Use a file, sandpaper, or a deburring tool to smooth out the edges, ensuring they are safe to handle. Pay close attention to corners and curves, as these areas are more prone to burrs. This step not only improves safety but also gives the sheet a polished appearance, making it easier to work with during installation.

Conclusion

Cutting steel roof sheets requires a combination of the right tools, proper preparation, and attention to safety. By understanding the characteristics of the material and selecting the appropriate cutting method, you can achieve clean, precise results every time. Always prioritize safety by wearing protective gear and securing your workspace. Thanks for reading our blog post on how to cut steel roof sheets! We hope you found it helpful and informative.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.