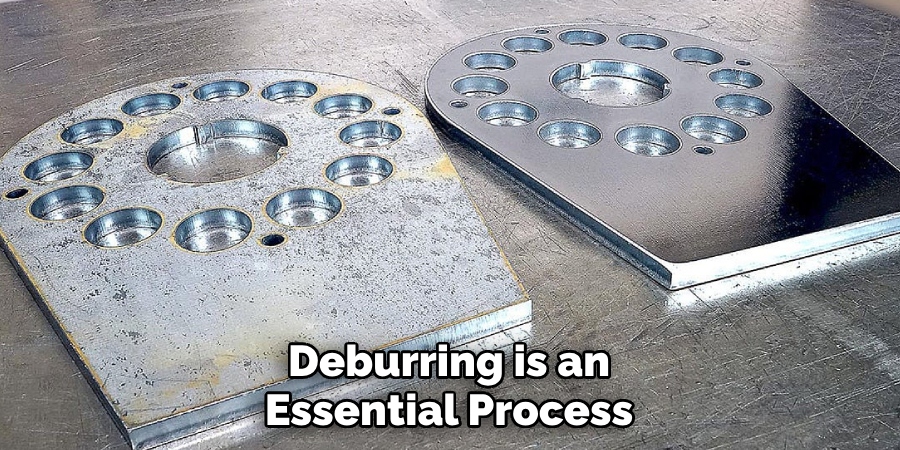

Deburring metal is an important process in the metalworking industry that involves removing unwanted or sharp edges from metal. These burrs can be a result of manufacturing processes such as drilling, milling, or cutting and if not removed, they can cause safety hazards and affect the overall quality of the final product.

The main objective of deburring metal is to remove any burrs or sharp edges that are created during the machining process. These burrs can cause serious injuries, damage to machinery and affect the overall quality of the product. Deburring metal not only ensures safety but also improves the functionality and appearance of metal parts. In this blog post, You will learn in detail how to deburr metal.

Step-by-step Instructions for How to Deburr Metal

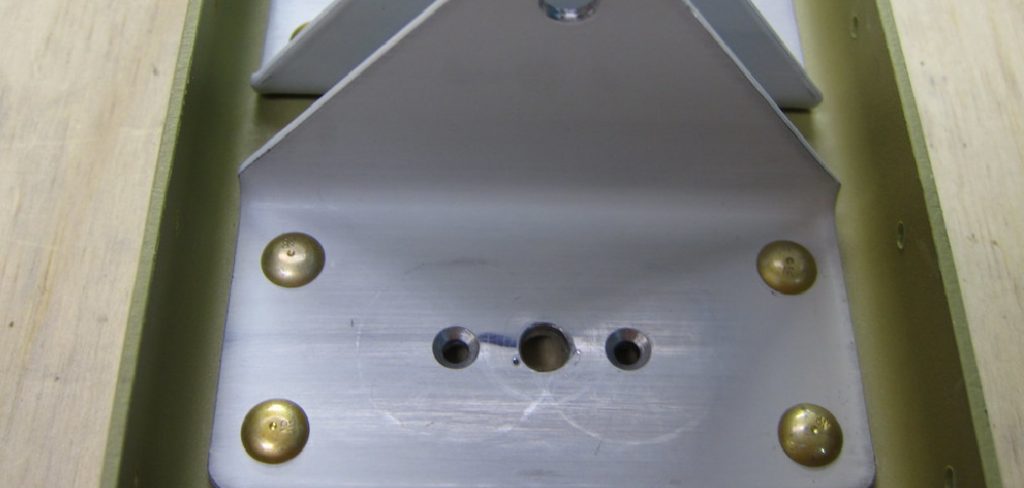

Step 1: Inspect the Metal Surface

Before you begin deburring, it is important to thoroughly inspect the metal surface to identify any burrs or sharp edges. This will help determine which areas need to be deburred and which tools are best suited for the job.

Step 2: Gather Your Tools

To effectively deburr metal, you will need a few essential tools. These may include a file, deburring blade, sandpaper, or a deburring machine. Make sure to have all necessary tools on hand before starting the process.

Deburring metal can produce sharp edges and debris that can be hazardous. It is important to wear protective gear such as gloves and safety glasses to avoid any injuries during the deburring process.

Step 3: Secure the Metal

To prevent any mishaps, make sure the metal piece is securely held in place. This can be done using a vise or clamps to keep it from moving while you work on deburring. Once you are fully prepared, begin by using a file or deburring blade to remove any large burrs or rough edges. Make sure to work in one direction to avoid creating new burrs on the metal surface.

Step 4: Use Sandpaper

For smaller, more delicate burrs, sandpaper can be an effective tool to smooth out the metal surface. Use a fine-grit sandpaper and work gently in circular motions until the edges are smoothed out. For larger or tougher burrs, a deburring machine may be necessary. These machines have rotating discs or brushes that can quickly and effectively remove burrs from metal surfaces.

Step 5: Clean the Metal Surface

After deburring is complete, it is important to thoroughly clean the metal surface. Use a cloth or compressed air to remove any debris or metal shavings from the surface. Once the surface is clean, carefully inspect it for any missed burrs. Use a magnifying glass if necessary to identify and remove any remaining burrs.

Step 6: Finish with Fine Sandpaper

To achieve a smooth and polished finish, use a fine-grit sandpaper to lightly buff the surface. This will remove any remaining imperfections and leave the metal surface smooth and ready for use.

To prevent burrs from forming in the first place, it is important to regularly maintain your tools and equipment. Keep blades sharp and clean, and inspect metal pieces for any burrs after each use.

Precautions for How to Deburr Metal

- The first and foremost safety tip for deburring metal is to wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and a face mask. Metal shavings can cause serious injuries if they come into contact with your skin or eyes.

- Make sure you have the right tools for the job. Improper tools can lead to accidents and injuries. Use deburring knives, files, or sandpaper to remove the burrs from the metal.

- Always inspect the metal for sharp edges before starting the deburring process. If you notice any jagged or uneven edges, smooth them out first with a file before using a deburring tool.

- When working with powered deburring tools, always make sure to disconnect the tool from its power source before changing blades or performing maintenance. Failure to do so can result in accidental activation and potential injuries.

- Keep your work area clean and well-lit. This will help you see the metal more clearly and avoid any hidden burrs that may go unnoticed. It also helps prevent accidents caused by cluttered workspaces.

- Properly dispose of all metal shavings and debris. These can be sharp and dangerous if left lying around. Use a magnet to collect any small metal pieces, and always sweep or vacuum the area after deburring.

- Always follow the manufacturer’s instructions when using deburring tools. Different tools may have specific safety measures that you need to adhere to for safe operation.

- Remember to take breaks and rest your hands regularly. Deburring can be a repetitive task that may cause strain on your hands and wrists if done for extended periods without breaks.

Remember, safety should always be the top priority when it comes to deburring metal. By following these precautions, you can ensure a safer and more efficient deburring process.

Are There Different Techniques for Deburring Different Types of Metal?

Deburring is an essential process in metalworking, which involves removing any rough or sharp edges on a metal surface. This could be done manually using hand tools such as files, sandpaper, and deburring knives. However, this method can be time-consuming and may not result in the desired smoothness.

To achieve better results, it is important to understand that different metals require different techniques and tools for deburring. In this section, we will discuss the various techniques that can be used to deburr different types of metal.

1. Steel

Steel is a common type of metal used in many industries, and it can come in various forms such as stainless steel, carbon steel, and alloy steel. Depending on the type of steel being worked on, different deburring techniques may be required.

- For stainless steel, a popular method is using ceramic media tumbling. This involves placing the steel parts in a tumbler along with ceramic media and allowing them to tumble against each other. The friction caused by the tumbling action helps remove any burrs or sharp edges.

- Carbon steel, on the other hand, can be deburred using abrasive blasting. This technique involves propelling small particles at high speed onto the surface of the steel, which helps to remove any burrs or imperfections.

- For alloy steel, a combination of both techniques may be used depending on the specific alloy and the severity of the burrs.

2. Aluminum

Aluminum is another common metal that is known for its lightweight and corrosion-resistant properties. However, it can be challenging to deburr due to its softness.

- One effective method for deburring aluminum is using chemical etching. This involves dipping the aluminum parts into a solution that dissolves the burrs without damaging the underlying metal surface.

- Another technique is using nylon brushes or wheels to remove any sharp edges manually. This works well for smaller and more delicate aluminum parts.

3. Copper

Copper is a soft metal often used in electrical and plumbing applications. Deburring copper typically involves removing any burrs from the edges of pipes or wires.

- A popular method for deburring copper is using a deburring tool specifically designed for pipes. This tool features blades that can be inserted into the pipe to remove any burrs as it is rotated.

- For smaller copper wires, use a wire brush or sandpaper can be used to remove any sharp edges manually.

Different types of metal require different techniques for deburring. It is important to understand the properties of the metal being worked on and choose the appropriate method and tools for deburring. This will result in a smoother and safer finished product. Remember to always wear protective gear and follow safety guidelines when deburring metal.

What Are Some Common Mistakes to Avoid When Deburring Metal?

When it comes to deburring metal, there are a few common mistakes that can often be overlooked. Knowing how to avoid these mistakes can help you achieve the best results and save time and effort in the process.

One of the most common mistakes when deburring metal is not properly preparing the surface before starting. This includes cleaning any oils, dirt, or debris from the metal surface to ensure a smooth and uniform result. Not preparing the surface can lead to incomplete deburring, as well as increased wear on tools and equipment.

Another mistake is using incorrect or dull deburring tools. It is important to use the right tool for the specific type of metal being deburred, as well as ensuring that the tool is sharp and in good condition. Using a dull tool can result in uneven or ineffective deburring, and may even cause damage to the metal surface. Improper technique is also a common mistake when deburring metal.

It is important to always follow the proper techniques for deburring, such as using light pressure and making smooth movements along the edge of the metal surface. Applying too much pressure or using erratic movements can lead to uneven deburring and potentially cause damage to the metal.

Conclusion

In conclusion, deburring metal is a crucial step in the manufacturing process for ensuring quality and safety. By removing sharp edges, burrs and surface imperfections, the finished product is not only visually pleasing but also safe to handle.

To effectively deburr metal, it is important to choose the right tools and techniques based on the type of metal being used. Using files, sandpaper or specialized deburring tools can help to remove burrs and sharp edges.

Additionally, different techniques such as manual deburring, mechanical deburring or chemical deburring may be employed depending on the complexity of the part and the desired level of precision. I hope this article has been beneficial for learning how to deburr metal. Make Sure the precautionary measures are followed chronologically.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.