Are you looking to drill AR500 steel for your next project? If yes, then you have come to the right place. Look no further, as this guide will provide you with all the necessary information on how to properly drill AR500 steel.

How to drill AR500 steel requires precision and the right approach to ensure clean and accurate holes without damaging the material. Whether you’re working on a DIY project or a professional application, understanding the correct techniques and tools for drilling AR500 steel is essential. As a high-strength and wear-resistant material, AR500 steel is commonly used in various industries such as construction, mining, and military.

In this guide, we will walk you through the necessary steps and provide helpful tips to successfully drill AR500 steel, allowing you to accomplish your drilling tasks confidently and efficiently. Let’s get started!

What are the Benefits of Using AR500 Steel?

Before diving into the drilling process, it’s essential to understand the benefits of using AR500 steel. This high-strength and abrasion-resistant material offers various advantages, making it a popular choice in many industries.

- Durability: AR500 steel is known for its high durability, making it suitable for heavy-duty applications.

- Wear Resistance: Its hardness provides excellent wear resistance, making it ideal for use in harsh environments.

- Impact Resistance: AR500 steel is highly resistant to impacts, making it suitable for applications where the material will face constant impacts or heavy loads.

- Versatility: AR500 steel is versatile and can be used in a wide range of applications due to its strength and toughness.

What Will You Need?

Before diving into the drilling process, having all the necessary tools and materials ready is important. Here’s a list of items you will need:

- AR500 steel piece

- Drill press or handheld drill (preferably with variable speed)

- High-quality drill bits designed for hardened steel (such as carbide-tipped or cobalt drill bits)

- Cutting oil or lubricant

- Clamps

- Safety gear (such as safety glasses and gloves)

Investing in high-quality tools and materials is worth ensuring the best results. Using low-quality or improper tools can damage or break the drill bits, which can be costly and time-consuming.

10 Easy Steps on How to Drill Ar500 Steel

Step 1: Choose the Right Drill Bit

Selecting the correct drill bit is crucial for drilling AR500 steel effectively. Use a high-quality drill bit specifically designed for cutting through hardened materials. Carbide-tipped or cobalt drill bits are highly recommended, as they can withstand the hardness of AR500 steel and maintain their sharpness during the drilling process. Avoid using standard or low-quality drill bits, as they will wear out quickly and may not penetrate the material effectively.

Step 2: Secure the Steel Properly

Before you begin drilling, securing the AR500 steel firmly in place is essential. Use sturdy clamps to hold the steel piece on a stable work surface. This will prevent the material from moving during the drilling process, ensuring precision and reducing the risk of injury. Make sure the steel is flat and stable to avoid any wobbling, which could affect the accuracy of the hole or damage the drill bit. If you’re using a drill press, ensure the steel is positioned correctly on the drill press table and clamped securely.

Step 3: Mark Your Drilling Point

Use a marker or a center punch to mark where you want to drill the hole. A center punch is beneficial as it creates a slight indentation in the steel, preventing the drill bit from wandering when you start drilling. Ensure the markings are clear and accurate, as the precise placement will help achieve the desired results. Taking the time to mark the drilling point properly will save you from having to redo the process later.

Step 4: Apply Cutting Oil or Lubricant

Before starting the drill, apply a generous amount of cutting oil or lubricant to the marked drilling area. Cutting oil reduces heat and friction during drilling, which is crucial when working with hard materials like AR500 steel. Proper lubrication will extend the lifespan of your drill bits and ensure smoother drilling. Reapply the cutting oil as needed throughout the drilling process to maintain optimal performance and prevent overheating.

Step 5: Set the Correct Drill Speed

Adjust the speed of your drill press or handheld drill to a lower RPM setting. Drilling AR500 steel requires steady, consistent pressure rather than high-speed drilling. A slow and controlled speed minimizes heat buildup, reduces the risk of damaging the drill bit, and enables a cleaner cut. Refer to the manufacturer’s specifications of your drill bits for guidance on the appropriate speed settings for hardened steel. Additionally, if you’re using a handheld drill, be sure to hold it firmly and maintain a steady hand throughout the process.

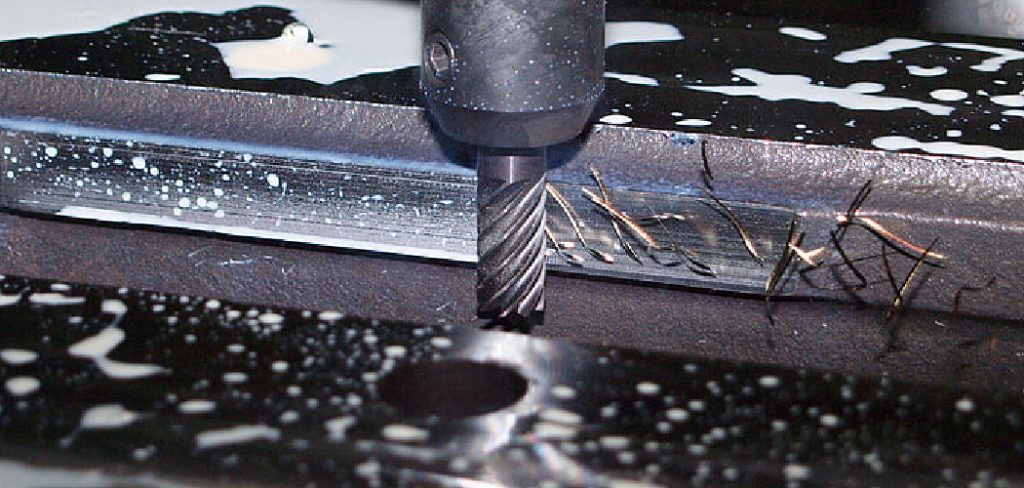

Step 6: Start Drilling

Begin drilling by slowly guiding the drill bit into the marked point using even pressure. Avoid forcing the drill, as excessive pressure can cause the bit to overheat or break. Allow the drill bit to do the work and maintain a steady pace. If you’re using a handheld drill, hold it perpendicular to the steel surface to achieve an accurate and clean hole. If needed, pause periodically to check progress and add more lubricant.

Step 7: Monitor Heat and Lubricate as Needed

During the drilling process, monitor the drill bit and the drilling area to ensure they are not overheating. Overheating can weaken the drill bit and compromise the hole’s quality. If you notice the area becoming excessively hot, stop drilling, allow the metal and bit to cool, and apply more cutting oil or lubricant before continuing. Consistent lubrication and heat management are key to a successful outcome. As the drill bit penetrates the steel, you may need to increase the pressure slightly.

Step 8: Clear Metal Shavings

Metal shavings, or chips, will accumulate as you drill into the AR500 steel. Periodically stop and remove these shavings from the hole and drill bit to prevent clogging and maintain precision. Use a small brush or air compressor to clear the shavings safely, and always wear gloves to protect your hands from sharp edges. Remember to clean the cutting oil or lubricant from the hole and drill bit before continuing.

Step 9: Complete the Hole

Continue drilling until you fully penetrate the AR500 steel and complete the hole. Maintain steady pressure and controlled speed throughout the process. Once the hole is complete, withdraw the drill bit carefully to avoid damaging the edges. Inspect the finished hole to ensure it’s clean and meets the required specifications. Avoid touching the hole while it’s still hot, as it can cause burns.

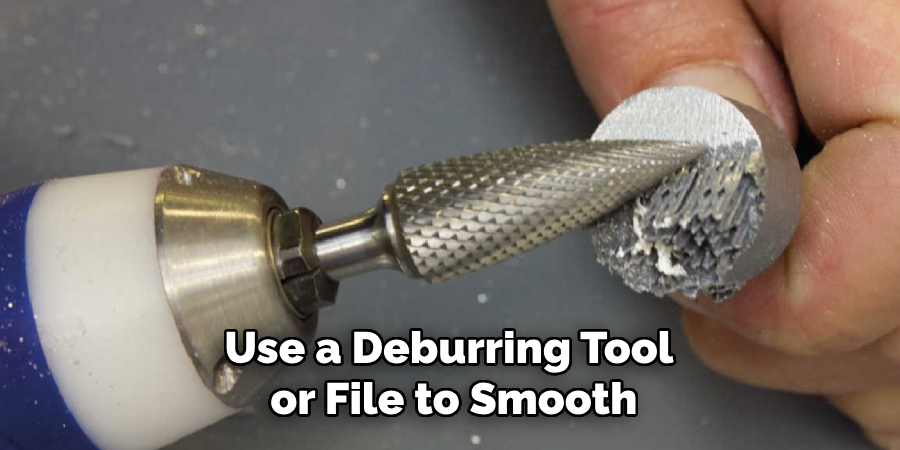

Step 10: Deburr the Edges

After drilling, use a deburring tool or file to smooth out any rough edges around the hole. Deburring not only enhances the appearance of the hole but also ensures safety by removing sharp or jagged metal fragments. Take your time to create a clean and professional finish. Remember always to wear safety gear when handling metal shavings and sharp edges.

By carefully following these steps, you can successfully drill into AR500 steel precisely and efficiently. With the right tools, preparation, and technique, you’ll be able to tackle your projects and get the most out of this durable material.

5 Additional Tips and Tricks

- Use the Right Drill Bits: One of the most critical factors in successfully drilling AR500 steel is using the correct type of drill bits. Since this type of steel is extremely tough, regular drill bits may not be able to penetrate it effectively.

- Choose the Right Drilling Speed: Another essential factor to consider when drilling AR500 steel is the speed at which you drill. Using a lower RPM (revolutions per minute) setting on your drill is recommended to prevent overheating and dulling of the bit. This will also help maintain control over the drilling process.

- Use Lubrication: Using a lubricant while drilling AR500 steel can significantly improve the effectiveness and lifespan of your drill bit. Lubricants help reduce friction and heat, making it easier to penetrate the steel’s harsh surface without damaging your equipment.

- Apply Steady Pressure: To avoid breaking or bending your drill bit, it is crucial to apply steady pressure while drilling through AR500 steel. This will prevent the bit from getting stuck or damaged due to excess force.

- Consider Investing in Specialty Drill Bits: For those who frequently work with AR500 steel, investing in specialty drill bits designed specifically for this type of steel can significantly improve the drilling process.

Following these additional tips and tricks can ensure a smoother and more successful drilling experience when working with AR500 steel.

Conclusion

How to drill AR500 steel may seem like a daunting task, but with the right tools and techniques, it can be done effectively and efficiently.

You can ensure a clean and precise hole in this tough material by using cutting oil or lubricant, setting the correct drill speed, and applying steady pressure. Remember to clear metal shavings deburr edges, and wear proper safety gear throughout the process. With practice and patience, you’ll become an expert at drilling into AR500 steel for all your projects.

So, remember these tips next time you work with AR500 steel to achieve professional results every time. Happy drilling!

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.