Drilling in cast iron can be a challenging task if you are not familiar with the material’s properties and the correct techniques. Cast iron is known for its hardness and brittle nature, which requires specific tools and methods to ensure a successful drilling process.

Understanding the right tools, such as high-speed steel or cobalt drill bits, and applying the proper amount of pressure during drilling are crucial steps. It’s essential to follow safety measures and take precautions to avoid damaging the material or your equipment.

This guide on how to drill in cast iron will walk you through the fundamental steps and tips to efficiently and safely drill in cast iron.

Why is Drilling in Cast Iron Challenging?

Drilling in cast iron presents several challenges, primarily due to its unique physical properties. Cast iron is a very brittle material, making it prone to cracking or breaking if not handled correctly. Unlike softer metals, it does not yield easily, necessitating the use of specialized drill bits like cobalt or high-speed steel to penetrate effectively. Additionally, the hardness of cast iron generates significant friction during the drilling process, which can lead to overheating and damaging both the drill bit and the workpiece.

The material’s propensity to produce powdery, abrasive cast iron chips instead of manageable curls further complicates the process by requiring frequent cleaning to maintain drill performance. These factors combined make drilling in cast iron a task that demands patience, precision, and proper technique.

Necessary Tools and Equipment

Before diving into the actual drilling process, it’s crucial to gather all the necessary tools and equipment. Here are the essential items you will need:

Protective Gear:

Safety glasses, gloves, and a face mask are essential to protect yourself from flying debris and dust during drilling.

Drill Press:

A drill press is the recommended tool for drilling in cast iron, as it offers more control, stability, and precision compared to a hand-held drill.

8 Step by Step Guidelines on How to Drill in Cast Iron

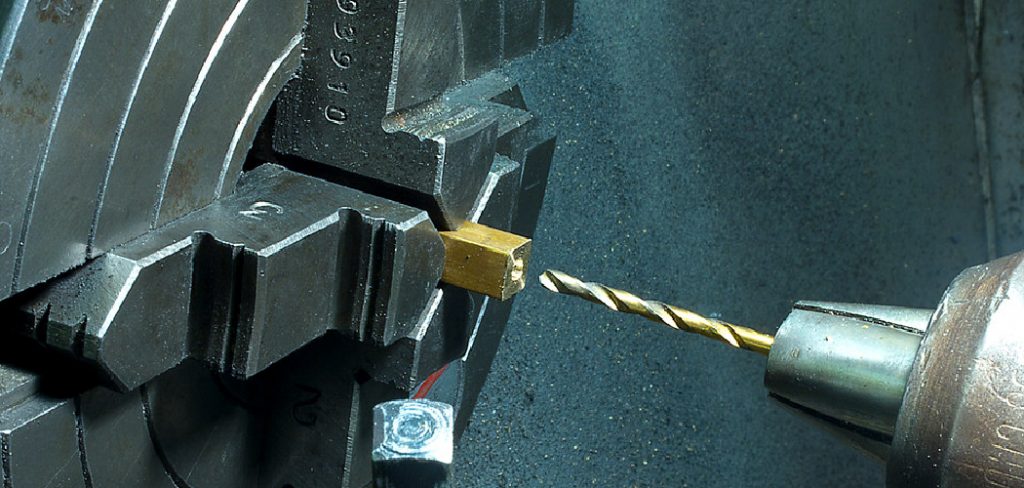

Step 1: Prepare the Drill Bit

The first step in drilling into cast iron is to ensure that your drill bit is prepared correctly. Select a high-quality drill bit made of high-speed steel or cobalt, as these materials are capable of handling the hardness of cast iron. Inspect the drill bit for any signs of wear or damage, such as chipping or dull edges, which can compromise the drilling process. Sharpen the drill bit if necessary to ensure maximum efficiency.

Additionally, it is recommended to use a drill bit with a split point design that reduces walking and provides more precise starting points on the hard surface of cast iron. Once the drill bit is ready, secure it firmly in the drill press chuck to ensure stability during the drilling operation.

Step 2: Use Appropriate Speed and Pressure

Cast iron is a hard material that requires the right amount of speed and pressure to penetrate effectively. It’s essential to use a drill press with adjustable speeds to have better control over the drilling process. Generally, slower speeds are better suited for drilling cast iron, as higher speeds can cause overheating and damage the workpiece or drill bit.

As for pressure, it’s crucial to apply consistent medium pressure while drilling instead of forcing the bit through the material. Too much pressure can result in snapping or breaking of the drill bit due to excessive friction.

Step 3: Mark Drill Point

Before starting the actual drilling process, mark your desired drill point with a center punch to create a small indentation that will act as a guide for the drill bit. This step is essential, especially when drilling into thicker pieces of cast iron, as it helps prevent the drill bit from wandering and ensures precise hole placement.

But be sure not to use excessive force when creating the indentation, as it can crack or damage the material.

Step 4: Apply Lubricant

To reduce friction and heat buildup during the drilling process, apply a lubricant like cutting oil or mineral oil on the drill bit and workpiece. This will also help prevent premature dulling of the drill bit’s edges.

It’s recommended to use a continuous stream of lubricant while drilling to maintain sufficient cooling and prolong the life of the drill bit.

Step 5: Start Drilling

With all the preparation done, it’s time to start drilling. To avoid overheating and damaging the material, take frequent breaks during the process. Every few seconds, lift the drill bit slightly away from the workpiece to remove any accumulated chips and allow for cooling before resuming.

Ensure that you are applying consistent medium pressure throughout the process and keep an eye on your drill press’s speed settings. If you notice any signs of excessive heat or dulling of the drill bit, stop immediately and let everything cool down before continuing.

Step 6: Clean Chips Regularly

As mentioned earlier, cast iron produces abrasive, powdery chips that can clog the drill bit and hinder its effectiveness. To avoid this, it’s crucial to clean the chips regularly during the drilling process by lifting the drill bit away from the workpiece and wiping off any accumulated debris.

The use of compressed air can also be helpful in removing stubborn chips from the drill bit’s flutes.

Step 7: Use a Backer Board

When drilling through thin pieces of cast iron, it’s recommended to use a backer board to support the material and prevent it from bending or breaking during drilling. A piece of scrap wood or metal works well as a backer board and provides stability for the workpiece.

But be sure to secure the backer board firmly in place before drilling to avoid any slipping or movement.

Step 8: Finish the Hole

Once the hole has been drilled through the cast iron, remove any remaining chips and debris from both sides of the workpiece using a wire brush or compressed air. You can also use a countersink tool to smooth out the edges of the hole for a cleaner finish.

And that’s it – you’ve successfully drilled into cast iron! Remember to clean and store your drill bits properly after use to ensure their longevity and effectiveness for future projects. With these guidelines on how to drill in cast iron, drilling in cast iron may seem like a daunting task at first, but with proper technique, patience, and the right tools, it can be a manageable and rewarding process.

Additional Tips for Drilling in Cast Iron

- Always wear protective gear to prevent injury from flying debris and dust

- Use sharp, high-speed steel or cobalt drill bits designed for drilling into hard materials

- Take frequent breaks to avoid overheating the material and drill bit

- Use a lubricant and clean chips regularly for a smoother drilling process

- Secure your workpiece firmly in place, especially when using a hand-held drill

- Avoid excess pressure to prevent snapping or breaking of the drill bit.

Furthermore, it’s crucial to choose the right type of drill press for your specific project needs. Some models may have special features like adjustable speeds and laser guides that can make drilling in cast iron even easier.

Frequently Asked Questions

Q1: Can I Use a Regular Drill to Make Holes in Cast Iron?

A: It is not recommended to use a regular hand-held drill for drilling into cast iron. A drill press with adjustable speeds and the ability to hold a larger, more stable piece of metal is better suited for this task. Using a hand-held drill can result in uneven holes and increase the risk of injury.

Q2: Can I Use Water as a Lubricant for Drilling in Cast Iron?

A: While water may seem like an easy and accessible lubricant, it is not recommended for drilling in cast iron. Water can cause rusting on the drill bit and workpiece, leading to poor results and potential damage.

Q3: How Do I Know if My Drill Bit is Dull?

A: Signs of a dull drill bit include slower drilling progress, increased heat buildup, and difficulty in removing chips. If you notice any of these signs, it’s best to stop and replace the drill bit before continuing. Always make sure to use sharp and quality drill bits designed for drilling into hard materials like cast iron.

Conclusion

Drilling into cast iron may initially appear challenging due to its hardness and the potential for brittleness. However, by following the steps and tips outlined in this guide on how to drill in cast iron, you can successfully complete the task with minimal errors or damage. Key elements to remember include using the right drill press and bits, applying consistent medium pressure, and ensuring proper lubrication.

Regularly cleaning chips and taking breaks are essential to reducing heat buildup and prolonging the lifespan of your drill bit. With patience and attention to detail, you can achieve precise and clean holes in cast iron, making your projects both efficient and rewarding.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.