Are you looking to fix engine compression? You’ve come to the right place!

Engine compression is a crucial aspect of an efficient and well-performing engine. When an engine’s compression starts to weaken, it can lead to various issues, such as decreased power, poor fuel efficiency, and engine misfires. However, there are steps you can take to address and fix engine compression problems. In this guide, we will explore some practical techniques and solutions to help you restore optimal engine compression and enhance your vehicle’s overall performance.

Whether you are a seasoned mechanic or a DIY enthusiast, these tips will assist you in diagnosing and resolving engine compression issues, allowing your engine to run smoothly and efficiently. Let’s dive into how to fix engine compression!

What Will You Need?

Before we get started, it’s essential to have the right tools at hand. You’ll need:

- Compression tester

- Wrenches and sockets (various sizes)

- Spark plug socket

- Air compressor

- Leak-down tester

- New spark plugs and gaskets (if necessary)

- Basic mechanic’s toolset

Once you have these tools, you’ll be ready to start fixing engine compression.

10 Easy Steps on How to Fix Engine Compression

Step 1: Diagnose the Problem

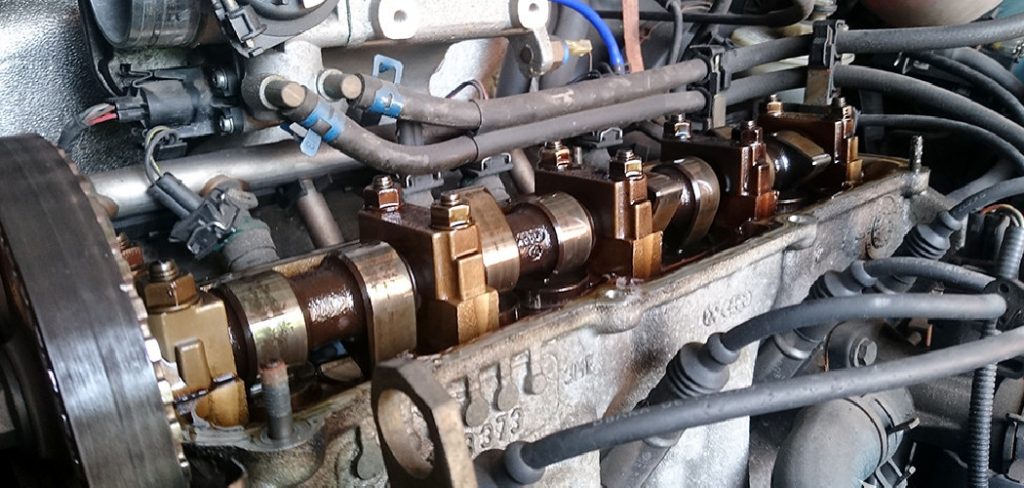

To diagnose the problem, you will first need to perform a compression test. Start by ensuring the engine is at operating temperature, as this will provide more accurate results. Then, disable the ignition and fuel systems by disconnecting the ignition coils or spark plug wires and unplugging the fuel injectors. Remove the spark plugs from each cylinder using a spark plug socket, and insert the compression tester into the spark plug hole of the cylinder you are testing.

Crank the engine several times, typically 4-6 revolutions, to get a compression reading. Record the pressure reading for each cylinder and repeat the process for all cylinders. Compare your results to the manufacturer’s specifications, typically found in the vehicle’s service manual.

Step 2: Identify Low Compression Cylinders

Once you have recorded the compression readings for all the cylinders, carefully analyze the results. Low compression in one or more cylinders is usually a sign of a problem. Common causes include damaged piston rings, worn or burnt valves, or a blown head gasket. Compare the readings to the manufacturer’s specifications to determine which cylinders are underperforming. If the difference in compression between cylinders exceeds 10-15%, it indicates an issue that needs to be addressed. Mark the low-compression cylinders for further inspection.

Step 3: Perform a Leak-Down Test

A leak-down test is an effective way to pinpoint the cause of low compression. Connect the leak-down tester to the identified cylinder using a leak-down tester and an air compressor. Ensure the engine is at the top dead center (TDC) for the cylinder’s compression stroke being tested. Gradually pressurize the cylinder using the leak-down tester and observe the percentage of air loss.

Listen for specific sounds to identify the source of the compression loss. Hissing from the intake manifold suggests an intake valve issue, while noise from the exhaust points to a problem with the exhaust valve. If you hear air escaping through the oil filler cap, it’s likely due to worn piston rings or a damaged cylinder wall. Bubbles in the coolant indicate a blown head gasket.

Step 4: Inspect and Repair the Problem

Based on the leak-down test results, inspect the corresponding engine components. If the issue is with the cylinder head, such as burnt valves or a blown head gasket, you may need to remove the cylinder head for further inspection and replacement of damaged parts. If the problem lies with the piston rings or cylinder walls, the engine will require a more in-depth repair, such as a piston or cylinder replacement. Ensure you use high-quality replacement parts to avoid future issues.

Step 5: Reassemble and Test

After completing the necessary repairs, reassemble the engine components carefully. Replace the spark plugs and gaskets, ensuring they are installed to the correct torque specifications. Once everything is reassembled, perform another compression test to verify that the problem has been resolved. Check for consistent compression readings across all cylinders to ensure the engine is balanced and functioning properly.

Step 6: Maintenance and Prevention

Maintenance and prevention are vital to ensuring the longevity and optimal performance of your engine. Here are some critical steps to follow:

- Regular Oil Changes: Keep your engine lubricated by adhering to the recommended oil change intervals. Fresh oil helps prevent friction and wear on engine components.

- Air Filter Replacement: Replace the air filter as your vehicle’s manufacturer recommends. A clean air filter ensures proper airflow and prevents contaminants from entering the engine.

- Fuel System Cleaning: Periodically clean the fuel system to remove deposits and maintain fuel efficiency. Consider using fuel additives or seeking professional fuel system cleaning services.

- Cooling System Maintenance: Regularly check the coolant level and ensure the cooling system is functioning correctly. Overheating can cause significant damage to the engine.

- Proper Driving Habits: Avoid aggressive driving, excessive idling, and over-revving the engine. These practices can strain engine components and decrease fuel efficiency.

Step 7. Seek Professional Help

If you cannot identify or resolve the compression issue independently, it’s always a good idea to seek help from a professional mechanic. Some engine repairs, such as machining a cylinder head or replacing piston rings, require specialized tools and expertise. A certified mechanic can accurately diagnose and perform repairs to ensure your engine operates safely and efficiently. While professional maintenance may involve additional costs, it can save time and prevent further damage from improper fixes. Always choose a reputable mechanic or repair shop with experience in engine diagnostics and repairs.

Step 8: Test Drive the Vehicle

Once the repairs are complete, take the vehicle for a test drive to ensure everything is functioning correctly. Pay attention to how the engine runs—listen for unusual noises, monitor the acceleration, and watch for any warning lights on the dashboard. A smooth-running engine and responsive performance indicate that the compression issue has been resolved. If any irregularities persist, you may need to recheck your work or return to a mechanic for further evaluation.

Step 9: Monitor Engine Performance Regularly

To avoid future issues, it’s important to monitor your engine’s performance continuously. Keep an eye on fuel efficiency, unusual engine noises, or a decrease in power, as these can indicate emerging problems. Periodic compression tests can also help you avoid potential issues, allowing you to address them before they lead to significant engine damage.

Step 10: Stay Proactive with Vehicle Maintenance

Finally, a proactive approach to vehicle maintenance is essential for keeping your engine running smoothly. Regularly scheduled maintenance, including oil changes, tune-ups, and inspections, can help extend the life of your engine and prevent costly repairs down the road. Keep track of recommended service intervals and address any issues promptly to ensure your vehicle operates at its best for years to come.

By following these steps and staying proactive with maintenance, you can keep your engine performing at its best and avoid potential compression problems in the future.

5 Things You Should

When it comes to fixing engine compression, there are certain pitfalls that you should steer clear of. Avoiding these common mistakes can save you time, money, and frustration. Here are five things you should avoid when addressing engine compression issues:

- Ignoring Regular Maintenance: Neglecting routine maintenance, such as oil changes and spark plug replacements, can lead to engine problems, including compression issues. Stay on top of regular maintenance to prevent compression issues from arising.

- Using Incorrect or Low-Quality Parts: When replacing parts related to engine compression, it’s essential to use the correct parts specified by the manufacturer. Using subpar or incompatible parts can lead to improper compression and further damage to the engine.

- Skipping Diagnostic Steps: Proper diagnosis is crucial for identifying the root cause of engine compression issues. Skipping or rushing through diagnostic steps can result in misdiagnosis and ineffective repair attempts. Take the time to conduct thorough diagnostics to pinpoint the exact problem.

- Overlooking External Factors: Sometimes, engine compression issues can be caused by external factors such as improper fuel, clogged air filters, or faulty sensors. It’s essential to consider and address these external factors alongside internal engine components to ensure a comprehensive fix.

- Attempting Complex Repairs Without Expertise: While DIY repairs can be rewarding, knowing your limits is essential. Complex repairs related to engine compression may require specialized knowledge and tools. If you need more clarification or are uncomfortable with the repair process, it’s best to seek professional assistance to avoid further complications.

By avoiding these common pitfalls, you can more effectively navigate the process of fixing engine compression, ensuring better outcomes and prolonging the lifespan of your engine.

Conclusion

How to fix engine compression issues doesn’t have to be an overwhelming task if approached with care and preparation.

By maintaining a regular service schedule, using quality components, following a thorough diagnostic process, and understanding your own repair limitations, you can address issues efficiently and effectively. Remember that taking preventive measures is just as important as performing the repair itself.

With these tips, you’ll be better equipped to maintain a healthy engine and enjoy a smoother driving experience for years to come.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.