Aluminum is a lightweight, durable, and versatile metal that is widely used in various industries, from construction to electronics. Identifying aluminum can be essential for recycling, manufacturing, or ensuring the correct material is used for a specific application. This guide aims to provide simple and effective ways on how to identify aluminum.

Applications of Aluminum

Aluminum’s unique properties make it suitable for a wide range of applications across different industries. Its lightweight yet strong structure makes it a preferred material in the aerospace and automotive industries, where reducing weight is crucial for efficiency and performance. Aluminum’s resistance to corrosion adds to its versatility, enabling its use in construction, such as in window frames, roofing, and cladding. Additionally, its excellent thermal and electrical conductivity makes it indispensable in the electronics and energy sectors, such as in wiring and heat exchangers. Aluminum is also widely used in food packaging, thanks to its ability to keep products fresh while being fully recyclable. Its adaptability, combined with sustainability, ensures aluminum remains a vital material in modern manufacturing and design.

Why Identifying Aluminum is Essential

Properly identifying aluminum is crucial for several reasons, particularly in industries where precision and quality are critical. For instance, in recycling, distinguishing aluminum from other metals ensures efficient sorting and processing, contributing to environmental sustainability and reducing waste. Similarly, in manufacturing, using the correct material is vital to achieving the desired performance, strength, and durability in finished products. Misidentifying metals can lead to structural weaknesses, increased costs, or even safety hazards, especially in sectors like construction and aerospace. Furthermore, identifying aluminum helps optimize resource allocation, ensuring that this valuable material is utilized effectively in its various applications.

Key Properties of Aluminum

Aluminum is known for its remarkable combination of properties that make it one of the most versatile metals. Firstly, it is exceptionally lightweight, with a density approximately one-third that of steel, which makes it ideal for applications where reducing weight is critical. Aluminum is also highly resistant to corrosion, thanks to a natural oxide layer that forms on its surface when exposed to air, protecting it from rust and degradation over time. Additionally, it boasts excellent thermal and electrical conductivity, making it a preferred choice for heat exchangers, electrical wiring, and other energy-related applications. Aluminum is non-magnetic and non-sparking, which is advantageous in industries requiring safety in environments involving flammable substances or sensitive magnetic equipment.

10 Methods How to Identify Aluminum

1. Visual Inspection of Color and Surface Finish

The first method to identify aluminum involves a simple visual inspection. Aluminum naturally exhibits a dull silver-gray color, often with a matte finish, though it can be polished to a high gloss. This is especially true for raw, uncoated aluminum. One of the key identifying features of aluminum is that it does not rust, which sets it apart from iron and steel that develop a reddish-brown rust over time. Aluminum, when exposed to air, forms a thin oxide layer that acts as a protective barrier, preventing further corrosion. However, if the aluminum is anodized, it may exhibit various colors, such as gold, bronze, or black, though the characteristic silver-gray is still evident.

2. Magnetic Test

Aluminum is a non-ferrous metal, meaning it does not have magnetic properties. To test for aluminum, use a magnet. Simply bring the magnet near the metal in question. If the magnet does not stick, the material is likely aluminum, as most ferrous metals like steel or iron are magnetic. This test is particularly useful for distinguishing aluminum from ferrous metals, especially when working with larger pieces. However, it’s important to note that some aluminum alloys, especially those containing small amounts of iron, might exhibit weak magnetic attraction. Still, aluminum remains largely non-magnetic in comparison to ferrous metals.

3. Weight Comparison

Aluminum is known for being lightweight compared to other metals, particularly when compared to steel, iron, or copper. If you have a known sample of steel or another material to compare, the difference in weight will be immediately noticeable. Aluminum is about one-third the weight of steel, which makes it easy to carry and manipulate. A simple method for identifying aluminum is to hold it in your hand and compare its heft to that of another material of the same size. Aluminum’s lightness is an inherent characteristic, making it a great material for applications where weight is a critical factor, such as in the automotive or aerospace industries.

4. Scratch Test

Another way to identify aluminum is by performing a scratch test. Aluminum is a relatively soft metal compared to steel or titanium, so it is more easily scratched. Using a sharp tool, such as a knife or a metal scribe, gently scratch the surface of the material. If the metal is aluminum, you’ll notice that it scratches relatively easily, leaving visible marks. Steel or other harder metals, on the other hand, will be resistant to scratching and may require more effort to mark the surface. This test is particularly useful when you are unsure whether a material is aluminum or a harder metal.

5. Thermal Conductivity Test

Aluminum has excellent thermal conductivity, which means it quickly absorbs and distributes heat. One way to identify aluminum is to conduct a simple heat test. For example, place a metal object under a heat source or touch it to determine how quickly it heats up. If the material is aluminum, it will warm up rapidly compared to metals with lower thermal conductivity, such as steel or iron. Aluminum is widely used in cookware and heat exchangers for this very reason. This method works well when dealing with thin, flat sections of metal, such as pans, radiators, or heat sinks.

6. Electrical Conductivity Test

Another key property of aluminum is its high electrical conductivity, second only to copper among metals. If you’re able to access the right equipment, you can measure the material’s conductivity using a multimeter. Aluminum conducts electricity much better than most other metals except for copper. The high electrical conductivity of aluminum makes it suitable for use in electrical transmission lines and wiring. If you’re working in electrical applications and need to verify that a wire or component is aluminum, use the multimeter to test for electrical flow. This can definitively confirm the presence of aluminum, especially when compared to non-conductive materials like plastic or ceramics.

7. X-Ray Fluorescence (XRF) Analysis

For the most precise identification of aluminum, especially when it is alloyed with other metals, X-ray fluorescence (XRF) analysis is a non-destructive method. This technique works by directing X-rays onto the material, which causes atoms in the material to emit secondary X-rays. These secondary X-rays are then analyzed to determine the metal’s composition. XRF is widely used in scrap metal recycling and material science because it can quickly and accurately identify the elements present in a sample. It’s particularly useful for distinguishing aluminum alloys, as the presence of other metals like copper, magnesium, or zinc can be detected.

8. Acid Reaction Test

Aluminum reacts distinctively to acids, which can help in identifying it. For example, if you apply hydrochloric acid (diluted to a safe concentration) to an aluminum surface, the metal will react by producing hydrogen gas and bubbling or fizzing. This is a unique reaction specific to aluminum and other metals like zinc, but much less common in ferrous metals. To test for aluminum, carefully apply a small amount of acid to an inconspicuous area. If you observe effervescence, the material is likely aluminum. This test should be conducted with caution, as strong acids can be dangerous and should be handled with proper safety equipment.

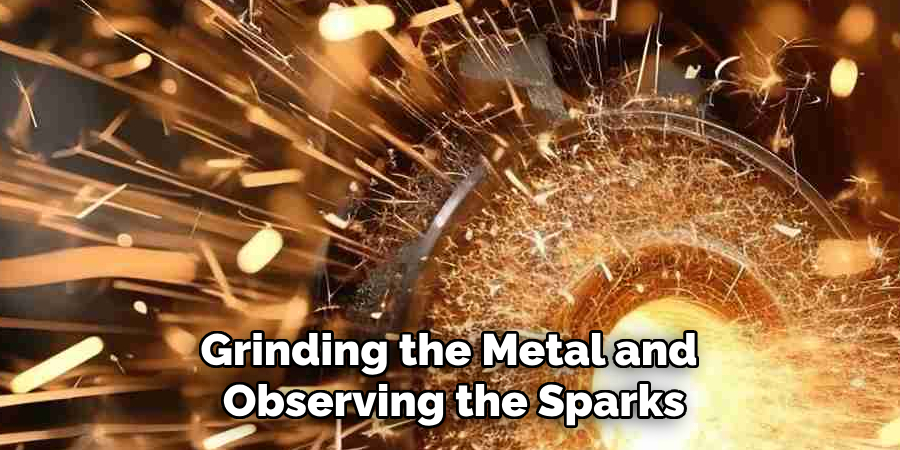

9. Spark Test

The spark test involves grinding the metal and observing the sparks it produces. Each metal produces a distinct type of spark when subjected to a grinder. When grinding aluminum, the metal produces short, bright white sparks that are relatively uniform and do not branch out. Steel, on the other hand, generates long, orange sparks that branch and spread in multiple directions. This method can be used in metalworking shops or when working with scrap metal to differentiate aluminum from steel or other harder metals. However, it’s not always suitable for thin materials, and the sparks can sometimes be subtle depending on the alloy.

10. Anodizing Inspection

Anodizing is a common process used to protect aluminum from corrosion by increasing the thickness of its natural oxide layer. If the material is anodized, it may have a slightly textured surface, often with a matte or colored finish. To identify anodized aluminum, inspect the surface for uniformity and texture. Anodized aluminum may also exhibit a more durable and scratch-resistant finish compared to untreated aluminum. The anodizing process often imparts a unique color to the metal, ranging from gold and bronze to black or clear finishes. If you suspect the material is aluminum and it shows signs of anodization, it is likely aluminum or an aluminum alloy.

Conclusion

Identifying aluminum among various materials requires a combination of observation and testing methods. From its lightweight characteristic and soft texture to its distinct thermal and electrical conductivity, aluminum stands out due to its unique properties. Techniques such as the scratch test, thermal conductivity test, and spark test offer practical approaches for quick identification, while advanced methods like X-Ray Fluorescence (XRF) analysis provide accurate and detailed results. So, there you have it – a quick and easy guide on how to identify aluminum.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.