Insulating copper pipes is crucial for maintaining water temperature, preventing condensation, and protecting against freezing in colder climates.

Proper insulation not only improves energy efficiency but also extends the lifespan of plumbing systems by reducing thermal stress.

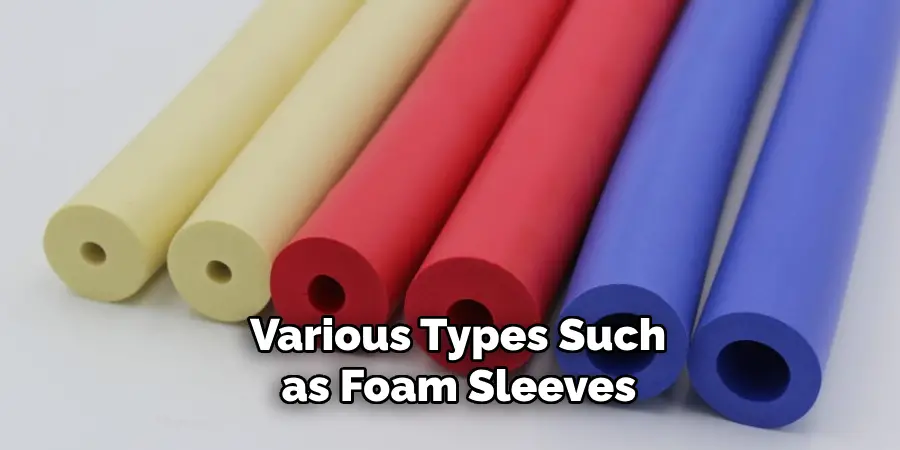

This guide explores essential techniques and materials for how to insulate copper pipe, whether for hot or cold water lines. From choosing the right insulation type, such as foam sleeves or fiberglass wraps, to properly measuring and securing insulation around pipes, each step ensures optimal performance.

Understanding the benefits of insulation, such as reduced energy costs and fewer plumbing repairs, empowers homeowners to safeguard their pipes against temperature fluctuations and environmental factors.

By implementing these insulation methods, homeowners can enhance comfort, conserve energy, and maintain the reliability of their plumbing infrastructure year-round.

Understanding the Need for Pipe Insulation

Effective pipe insulation is a fundamental aspect of home maintenance that addresses several key concerns. Firstly, it plays a pivotal role in energy conservation by minimizing heat loss from hot water pipes and preventing heat gain in cold water pipes.

This ensures that less energy is required to maintain desired temperatures, leading to lower utility bills. Secondly, insulation helps to mitigate condensation on cold water pipes, which can lead to moisture-related issues such as mold growth and structural damage.

Additionally, in colder climates, insulating pipes is a critical measure to prevent freezing, which can cause pipes to burst and result in costly repairs.

By understanding these needs, homeowners can appreciate the importance of proper pipe insulation in enhancing the efficiency and safety of their plumbing systems.

Tools and Materials Needed

To effectively insulate copper pipes, you will need a variety of tools and materials to ensure a thorough and professional job. The key materials include:

- Pipe Insulation: Available in various types such as foam sleeves, fiberglass wraps, and rubber insulation. Selection depends on the specific requirements of your project.

- Insulation Tape: Used to secure insulation wraps and ensure a tight seal around the pipes.

- Utility Knife or Scissors: Essential for cutting the insulation material to the correct length and size.

- Measuring Tape: Required to measure the length of pipes and the insulation material accurately.

- Zip Ties or Wire: Used to secure insulation in place, particularly at bends and junctions.

- Gloves and Safety Goggles: Protective gear to ensure safety while handling insulation materials and cutting tools.

- Sealing Compound or Duct Tape: Provides additional sealing at the ends of the insulation to prevent air gaps and enhance efficiency.

Having these tools and materials ready will streamline the insulation process and ensure that your copper pipes are adequately protected against temperature variations and environmental damage.

10 Methods How to Insulate Copper Pipe

1. Foam Pipe Insulation

Foam pipe insulation is one of the most common and effective methods for insulating copper pipes. These pre-slit, tubular foam sleeves are made from polyethylene or rubber and are easy to install.

To use foam pipe insulation, simply measure the length of the pipe you need to insulate and cut the foam sleeve to fit. Open the slit and wrap the sleeve around the pipe, ensuring a snug fit. Seal the seams with adhesive or duct tape to prevent heat loss or condensation. Foam insulation provides excellent thermal protection and is suitable for both hot and cold water pipes.

2. Fiberglass Pipe Insulation

Fiberglass pipe insulation is another effective option, particularly for high-temperature applications.

This insulation comes in pre-formed sleeves or rolls and includes a vapor barrier to prevent condensation. To install fiberglass pipe insulation, measure and cut the insulation to fit the length of the pipe.

Wrap the insulation around the pipe, overlapping the seams to ensure complete coverage. Secure the insulation with tape or wire to hold it in place. Fiberglass insulation is durable and provides excellent thermal resistance, making it ideal for insulating copper pipes in hot water systems.

3. Rubber Pipe Insulation

Rubber pipe insulation, also known as elastomeric insulation, is flexible, durable, and resistant to moisture. It is suitable for both hot and cold water pipes and is especially useful in environments with fluctuating temperatures. To install rubber pipe insulation, measure and cut the insulation to the required length.

Open the slit and wrap the insulation around the pipe, ensuring a tight fit. Use adhesive or self-sealing seams to close the insulation around the pipe. Rubber insulation provides excellent thermal protection and is resistant to mold and mildew, making it a versatile choice for insulating copper pipes.

4. Foil-faced Bubble Wrap

Foil-faced bubble wrap is a lightweight and effective insulation material that combines reflective foil and air pockets to reduce heat transfer. This type of insulation is ideal for insulating copper pipes in unconditioned spaces, such as attics and basements.

To install foil-faced bubble wrap, measure and cut the material to fit the length of the pipe. Wrap the bubble wrap around the pipe, overlapping the seams to ensure full coverage. Secure the insulation with tape or zip ties.

5. Heat Tape or Heat Cable

Heat tape or heat cable is an excellent solution for preventing pipes from freezing in cold weather. These electrical devices generate heat when wrapped around pipes, maintaining a temperature above freezing.

To use heat tape or heat cable, measure the length of the pipe and cut the tape or cable to fit. Wrap it around the pipe, following the manufacturer’s instructions for spacing and securing. Connect the tape or cable to a power source and ensure it is properly grounded.

6. Spray Foam Insulation

Spray foam insulation is a versatile and effective method for insulating copper pipes, especially in hard-to-reach areas or irregularly shaped spaces. This insulation material expands upon application, filling gaps and creating a tight seal around the pipes. To use spray foam insulation, apply the foam directly to the pipes using a spray nozzle.

Ensure even coverage and avoid over-application, as the foam will expand. Allow the foam to cure according to the manufacturer’s instructions before using the pipes. Spray foam insulation provides excellent thermal resistance and can also help reduce noise from water flow.

7. Pipe Wrap Insulation Tape

Pipe wrap insulation tape is a convenient and flexible solution for insulating copper pipes, particularly in tight spaces or around bends. This tape is made from materials such as rubber, foam, or fiberglass and is available with or without adhesive backing.

To use pipe wrap insulation tape, measure the length of the pipe and cut the tape to the required size. Wrap the tape around the pipe, overlapping each layer by at least half the tape’s width to ensure complete coverage. Secure the ends with tape or ties.

8. Armaflex Insulation

Armaflex insulation is a type of closed-cell foam insulation specifically designed for pipes and HVAC systems. It is flexible, durable, and resistant to moisture, making it an excellent choice for insulating copper pipes. To install Armaflex insulation, measure and cut the insulation to fit the length of the pipe.

Open the slit and wrap the insulation around the pipe, ensuring a snug fit. Use adhesive or self-sealing seams to close the insulation around the pipe. Armaflex provides superior thermal resistance and is resistant to mold and mildew, making it a reliable choice for both hot and cold water pipes.

9. Reflective Pipe Wrap

Reflective pipe wrap combines the benefits of traditional insulation with the added advantage of reflective surfaces that reduce radiant heat loss. This type of insulation is suitable for both hot and cold water pipes and is particularly effective in unconditioned spaces.

To install reflective pipe wrap, measure and cut the material to fit the length of the pipe. Wrap the insulation around the pipe, overlapping the seams to ensure full coverage. Secure the insulation with tape or zip ties.

The reflective surface helps to deflect radiant heat, while the underlying insulation material provides thermal resistance, making this an effective method for insulating copper pipes.

10. Insulated Pipe Sleeves

Insulated pipe sleeves are pre-formed insulation products designed to fit snugly around copper pipes.

These sleeves are typically made from foam, rubber, or fiberglass and come in various sizes to accommodate different pipe diameters. To use insulated pipe sleeves, measure the length of the pipe and cut the sleeve to fit. Slide the sleeve over the pipe, ensuring a tight fit and proper alignment with any joints or bends.

Seal the seams with adhesive or tape to prevent heat loss or condensation. Insulated pipe sleeves provide excellent thermal protection and are easy to install, making them a practical choice for insulating copper pipes.

Conclusion

Insulating copper pipes is essential for maintaining an efficient and reliable plumbing system. Each of the ten methods described above offers unique benefits and is suited to different applications and environments.

From simple solutions like foam pipe insulation and pipe wrap tape to more advanced options like heat tape and spray foam insulation, there are methods to meet a variety of needs.

Proper insulation helps prevent heat loss, condensation, and freezing, reducing energy costs and prolonging the lifespan of your plumbing system. Thanks for reading, and we hope this has given you some inspiration on how to insulate copper pipe!

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.