Torque is the rotational force applied to an object, such as a bolt, causing it to rotate around an axis. This force is essential in many mechanical applications, ensuring that components are securely fastened without causing damage.

Accurate torque measurement is critical in preventing over-tightening, which can strip threads or weaken material, and under-tightening, which can result in loose bolts and potential structural or mechanical failure.

Torque measurement is crucial across various industries, including automotive, construction, and maintenance. Properly tightening bolts ensures equipment and structures’ safety, reliability, and longevity.

The purpose of this article is to provide a comprehensive, step-by-step guide on how to measure torque on a bolt effectively. By following this guide, users can ensure accurate torque application, enhancing safety and performance across their projects. Understanding and implementing correct torque measurement practices is essential for both professionals and DIY enthusiasts.

Understanding Torque and Its Importance

What Is Torque?

Torque is the product of force applied at a distance from an axis of rotation, creating a twisting or turning motion. To visualize it, think of using a wrench to rotate a bolt—both the amount of force you exert, and the length of the wrench handle contribute to the torque.

Torque is measured in units such as Newton meters (Nm) in the metric system or foot-pounds (ft-lbs) in the imperial system. These units quantify the rotational force required to tighten or loosen fasteners effectively, making torque a pivotal concept in mechanical processes.

Why Proper Torque Is Critical

Applying incorrect torque can have serious consequences, such as bolts loosening over time or being overly tightened, which can strip threads or damage components. Loose bolts can lead to structural instability or mechanical failures while over-tightening can compromise the equipment’s integrity. Both scenarios pose safety risks and can lead to costly repairs or accidents.

Adhering to manufacturer-specified torque values ensures that components are secured effectively without damage. Thus, using the correct torque not only enhances the performance and longevity of the assembly but also prevents unforeseen hazards, making it a crucial practice in professional and personal applications.

Tools Required for Measuring Torque

Torque Wrenches

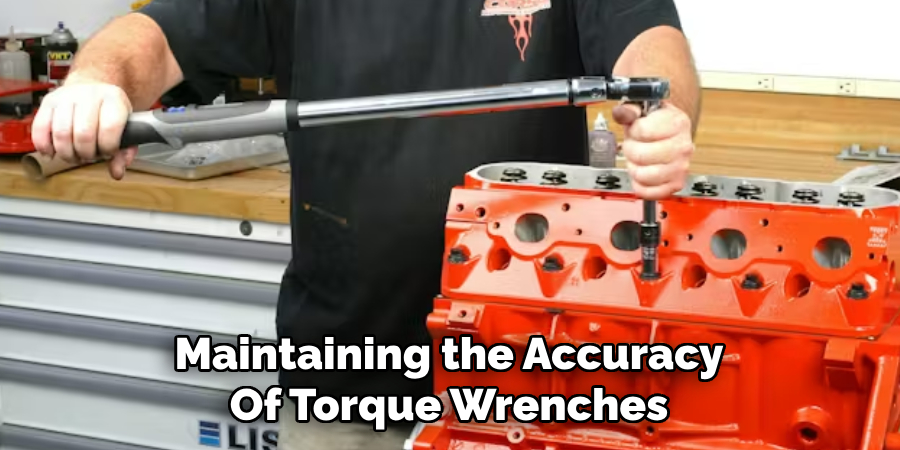

Torque wrenches are indispensable tools for accurately measuring and applying torque to bolts. There are several types, each suited to different applications. Beam torque wrenches are simple, reliable, and affordable, making them ideal for basic tasks. Click torque wrenches are widely popular due to their ease of use and audible “click” signal when the target torque is reached.

Digital torque wrenches provide precise readings and advanced features like memory storage, making them perfect for high-accuracy requirements. Split-beam wrenches are robust and low-maintenance, commonly used in professional settings. When choosing the right torque wrench, consider factors such as required accuracy, budget, and frequency of use.

Supporting Tools

Several supporting tools are often necessary to complement the torque wrench for optimal performance. Socket sets, extensions, and adapters ensure compatibility with a wide range of bolt sizes and access to hard-to-reach areas. Torque multipliers can be used when higher torque values are required, allowing for efficient force application without exerting excessive effort.

Additionally, calibration devices are optional but essential for maintaining the accuracy of torque wrenches over time. By having the right supporting tools, users can streamline their torque measurement process, ensuring precision and reliability across diverse applications.

Preparing for Torque Measurement

Inspecting the Bolt and Threads

Before beginning torque measurement, thoroughly inspecting the bolt and its threads is crucial. Ensure that the threads are clean and free from debris, dirt, or rust, as these can affect the accuracy of torque application and lead to inconsistent results.

Damaged or corroded threads should be repaired or replaced to maintain the integrity of the connection. If specified by the manufacturer, apply appropriate lubrication to the threads. Lubrication helps reduce friction, allowing for precise torque application while preventing thread seizing or galling. By taking these steps, you can achieve optimal results and prolong the longevity of the components.

Setting Up the Torque Wrench

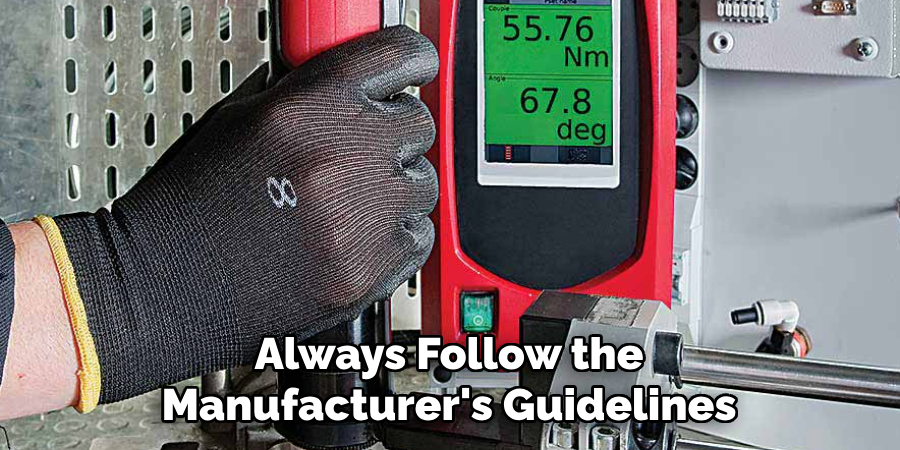

Properly setting up the torque wrench prior to use is essential for accurate measurements. Begin by calibrating the wrench if required, as regular calibration ensures its accuracy and reliability. Follow the manufacturer’s instructions for calibration or seek professional calibration services for more precise adjustments.

Once calibrated, adjust the torque wrench to the desired torque setting by referencing the specifications provided for the application. Confirm the setting by checking the scale or digital display, depending on the wrench type. Ensuring the tool is correctly set helps prevent errors during measurement, promoting safety and high-quality results.

How to Measure Torque on A Bolt: Step-by-Step Guide

Attaching the Wrench to the Bolt

The first step in accurately measuring torque is securely attaching the torque wrench to the bolt. Begin by selecting the correct socket size that fits snugly over the bolt head. A proper fit ensures a secure grip, preventing slippage or damage to the bolt head during tightening.

Carefully attach the socket to the torque wrench, ensuring it is firmly in place and locked if your tool has a locking mechanism. Once the socket is ready, position the torque wrench perpendicular to the bolt.

This alignment is essential for ensuring precise torque readings, as any angular misalignment can result in inaccurate measurements. Securing the wrench and maintaining a proper position set the foundation for an effective torque application process.

Applying Force to Achieve Target Torque

After attaching the wrench, the next step is to apply force gradually to tighten the bolt while monitoring the torque wrench closely. Hold the torque wrench firmly and apply steady pressure to the handle. Avoid jerky or uneven motions, as these can lead to inconsistent torque application.

Continue tightening the bolt until the target torque is reached. Depending on the type of torque wrench you are using, the mechanism will indicate when this target is achieved. For example, a click wrench will emit a distinct audible “click,” signaling that the desired torque has been applied.

A visual or auditory prompt, such as a light or beep, will indicate success on digital torque wrenches. Once the target is achieved, stop applying force immediately to avoid over-tightening, which can cause damage to the threads or components. This measured and attentive approach ensures precision and consistency, safeguarding the assembly’s integrity.

Measuring Residual Torque

Residual torque refers to the torque required to turn a bolt further after it has already been tightened. Measuring residual torque is a useful practice to verify the effectiveness of the initial tightening and ensure consistent, accurate results. Start by setting the torque wrench to the expected torque value for your application to measure residual torque.

Attach the wrench to the bolt as before, ensuring a secure and perpendicular grip. Begin turning the torque wrench gently in the tightening direction until the bolt moves. The torque reading at the point where the bolt begins to turn represents the residual torque. Some torque wrenches allow you to measure residual torque in reverse for additional accuracy.

Switch to reverse mode and carefully apply force in the opposite direction to measure the torque required to loosen the bolt. By measuring residual torque, you can confirm the bolt’s tightness and adherence to specifications, providing an added layer of confidence in your work.

Verifying and Adjusting Torque

Double-Checking the Torque Value

After the initial torque measurement, it is important to double-check the applied torque to ensure accuracy and consistency. This step is particularly vital for applications involving critical components where precise torque specifications are essential for safety and performance.

To recheck the torque value, use the same torque wrench and set, applying force to confirm the measurement matches the desired specification.

Additionally, when working with multiple bolts, ensure even torque distribution by following the manufacturer’s recommended tightening sequence, typically a star or diagonal pattern. This approach reduces the risk of warping or uneven force across the connected components, leading to a reliable and secure assembly.

Adjusting Incorrect Torque

If the initial torque measurement reveals that the bolt is over-tightened or under-tightened, adjustments may be necessary to bring the torque value in line with the given specification. To correct an over-tightened bolt, carefully loosen it by turning in the reverse direction and then retighten it while monitoring the torque wrench closely. For an under-tightened bolt, gradually apply force to achieve the correct torque.

Remember to recheck each adjustment with the torque wrench to confirm the revised value meets the exact requirement. Regularly verifying and adjusting torque ensures optimal performance, prevents damage to components, and maintains the overall safety of the assembly.

Common Mistakes and Troubleshooting Tips

Misusing the Torque Wrench

One common mistake when using a torque wrench is over-tightening, which can damage threads or deform components. To avoid this, make sure to stop applying force as soon as the wrench indicates the desired torque has been achieved, whether through a click, beep, or visual display.

Another frequent error is applying sudden, uneven force instead of gradual, steady pressure, which can result in inconsistent measurements and unreliable results.

Always handle the wrench with care to maintain precision. Additionally, regular torque wrench calibration is essential to ensure accurate performance over time. Follow the manufacturer’s recommended calibration schedule or seek professional services to prevent errors caused by an out-of-calibration wrench.

Incorrect Settings or Readings

Incorrect wrench settings or improper handling during use can lead to inaccurate torque application. Always set the wrench to the exact torque value specified for the job and double-check the setting before proceeding. Misreading the scale or digital display can result in applying the wrong torque, so take your time to confirm the value. Another issue can arise from using the wrench at an improper angle.

Maintaining a perpendicular alignment between the wrench and the bolt for precise readings. To ensure consistent results, apply steady pressure throughout the process without rushing or jerky movements. These precautions will help prevent measurement discrepancies and prolong the tool’s reliability.

Maintenance of Torque Tools

Cleaning and Storage

Proper maintenance of your torque wrench begins with cleaning it after each use. Use a soft, dry cloth to wipe away any dirt, grease, or debris that could affect its performance.

Avoid using harsh chemicals that might damage the tool’s materials. Once clean, store the wrench in a protective case to shield it from moisture, dust, and physical damage. Ensure the wrench is not subjected to drops or impacts, as these can disrupt its calibration and compromise accuracy.

Regular Calibration

Regular calibration is crucial to maintain the reliability of your torque wrench. For frequent use, calibrate the wrench every six months, but annual calibration may be sufficient for occasional use. Calibration ensures the tool’s readings remain accurate over time.

While DIY calibration is possible with the right equipment and expertise, professional calibration services are recommended for precise results and peace of mind. Always follow the manufacturer’s guidelines for calibration intervals.

Conclusion

Accurately measuring torque is essential for ensuring any assembly’s safety, reliability, and performance. Understanding how to measure torque on a bolt involves using the correct tools, such as a calibrated torque wrench, and adhering to specified torque values and tightening patterns.

Following proper procedures, verifying measurements, and adjusting as needed are critical to achieving consistent results. Regular maintenance of tools, including cleaning and calibration, ensures their longevity and precision. By practicing proper torque measurement techniques and prioritizing accuracy, you can reduce the risk of component failure and enhance the overall quality of your work.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.