Melting stainless steel is a complex process that is critical in various industrial applications. Stainless steel, known for its strength, corrosion resistance, and durability, is widely used in industries like construction, automotive, and manufacturing. However, learning how to melt stainless steel requires understanding its unique characteristics. Unlike many other metals, stainless steel has a significantly higher melting point—ranging from 2,500°F (1,370°C) to 2,750°F (1,510°C)—due to its alloy composition, which often includes elements like chromium, nickel, and molybdenum. These properties make stainless steel more challenging and demand specialized equipment and techniques.

This article provides a comprehensive guide on how to melt stainless steel, covering every aspect of the process. From understanding the required equipment and step-by-step melting procedures to implementing essential safety measures, this guide aims to equip readers with the knowledge needed for successful results.

Understanding Stainless Steel and Its Properties

Composition of Stainless Steel

Stainless steel is an alloy primarily composed of iron, chromium, nickel, and sometimes molybdenum. Chromium, a key component, provides the material with its characteristic corrosion resistance by forming a thin, protective oxide layer on the steel’s surface. Nickel enhances durability and improves resistance to extreme temperatures, while molybdenum contributes to additional strength and protection against chemical corrosion. Various types of stainless steel exist, such as 304 (commonly used for kitchenware due to its corrosion resistance), 316 (ideal for marine environments thanks to added molybdenum), ferritic (known for magnetic properties and cost-effectiveness), and martensitic (recognized for high strength and hardness). Each type has unique properties and melting requirements based on its composition.

Melting Point of Stainless Steel

The melting point of stainless steel typically falls within the range of 2,500°F (1,370°C) to 2,750°F (1,510°C), varying slightly based on the specific grade and alloy composition. For example, grades with higher chromium or molybdenum content tend to have marginally higher melting points. Factors such as the presence of impurities or additional alloying elements can also influence the melting process by altering the temperature required. Understanding these variances is crucial for precise melting, as an incorrect temperature can lead to oxidation, structural weaknesses, or compromised corrosion resistance in the finished product. Proper equipment and control are essential to manage these factors effectively.

Equipment Needed to Melt Stainless Steel

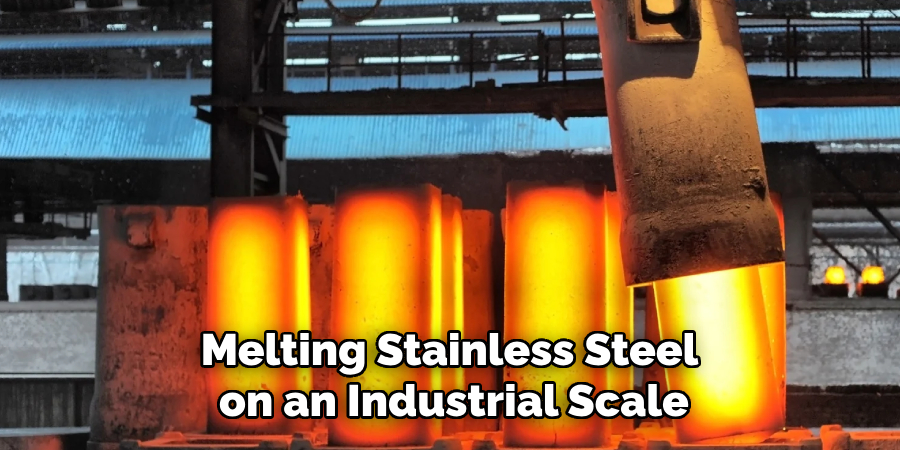

High-Temperature Furnace

Melting stainless steel on an industrial scale requires specialized high-temperature furnaces capable of reaching the material’s melting range of 2,500°F (1,370°C) to 2,750°F (1,510°C). Commonly used furnaces include induction furnaces, electric arc furnaces (EAF), and electric resistance furnaces. Induction furnaces, in particular, are widely favored for their efficiency and precision. These furnaces use induction coils to generate heat through electromagnetic fields, quickly raising the temperature of the metal. This method ensures uniform heating and minimizes contamination. On the other hand, electric arc furnaces utilize an electrical arc to achieve the necessary temperatures, making them ideal for large-volume melting. Each furnace type offers specific advantages based on the scale and requirements of the melting process.

Alternative Methods for Small-Scale Melting

For small-scale projects or repair work, alternative methods such as propane or oxy-acetylene torches can be used to melt stainless steel. These tools can generate sufficient heat for small quantities of metal, making them an accessible choice for hobbyists or minor repairs. However, small-scale methods come with significant limitations. Propane or oxy-acetylene torches may struggle to maintain consistent temperatures and often fail to fully melt stainless steel due to its high melting point. Additionally, these methods offer less control, increasing the risk of oxidation or uneven heating, which can lead to inferior results compared to industrial-grade processes.

How to Melt Stainless Steel: Step-by-Step Process

Preparing the Stainless Steel

Proper stainless steel preparation is crucial to ensure efficient melting and high-quality results. Begin by sorting the stainless steel pieces to identify and group them based on their type and grade. This step helps maintain consistency in melting and guarantees the final product meets the desired specifications. Next, clean the stainless steel to remove any contaminants, coatings, or debris, such as paint, oil, rust, or dirt.

These impurities can interfere with the melting process and degrade the quality of the molten steel. After cleaning, cut or shape the stainless steel into smaller pieces. This reduces melting time since smaller pieces heat up more quickly and evenly, optimizing energy usage. Lastly, verify that the selected type and grade of stainless steel align with the intended application. Different grades have varying properties and melting requirements, affecting the final product’s suitability for specific uses.

Setting Up the Furnace or Heating Equipment

Before starting the melting process, set up the furnace or heating equipment properly to ensure safe and efficient operation. Begin by heating the furnace to the target temperature, typically between 2,500°F (1,370°C) and 2,750°F (1,510°C), depending on the grade of stainless steel being melted. Achieving a precise temperature range is essential to avoid oxidation or structural inconsistencies.

Ensure the melting area is well-ventilated to safely manage fumes and high heat. Position the furnace or heating equipment in an open or properly ventilated facility and verify all safety protocols are in place. Use specialized tools such as tongs or crucibles designed for handling molten metal. These tools prevent accidents and contamination while offering greater control during the process. Additionally, wearing heat-resistant gloves, aprons, and protective eyewear is necessary to safeguard against accidents or splashes of molten steel during handling.

Melting the Stainless Steel

Once the setup is complete, load the prepared stainless steel pieces into the furnace or a crucible. Monitor the temperature closely to ensure it remains within the correct melting range for the type and grade of stainless steel being processed.

Adjust the heat as needed to maintain consistent temperatures throughout the melting process. As the steel heats, observe its physical changes—when fully melted, stainless steel becomes a shiny, reflective liquid. During this phase, it’s critical to maintain the appropriate temperature to prevent oxidation and minimize impurity contamination. Use temperature probes or other sensors to ensure precision and stability throughout the melt. After the steel has completely liquefied, additional steps like skimming off slag or introducing alloying elements may be performed, depending on the desired outcome. These adjustments help refine the molten steel and prepare it for subsequent processes like casting or forming.

Safety Precautions When Melting Stainless Steel

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential when melting stainless steel to guard against injuries caused by high temperatures, molten metal splashes, and harmful fumes. Heat-resistant gloves, protective eyewear, flame-resistant clothing, and face shields should always be worn during the process. Specialized heat-resistant gear is crucial to protect exposed skin from burns caused by direct contact with molten metal or equipment. Welding aprons and boots designed for high-temperature environments provide additional safety, ensuring that individuals working near the furnace are adequately shielded from intense heat and accidental splashes. Adhering to these measures significantly minimizes personal injury risks during the melting operation.

Environmental Safety

Ensuring environmental safety is equally important to create a safe workspace when melting stainless steel. Proper ventilation is critical to prevent inhaling toxic fumes, which may result from chemical reactions during the melting process. Harmful gases, such as chromium or nickel oxides, can be released at high temperatures, making a well-ventilated area essential for reducing exposure. High-capacity exhaust systems and air filtration can further improve air quality in the workspace. Additionally, safety protocols should address the risks associated with molten metal spills. Maintaining clear work zones and readily available spill containment tools can mitigate potential hazards, ensuring efficient handling of liquid steel without compromising safety.

Cooling and Handling Melted Stainless Steel

Cooling the Melted Stainless Steel

Gradual cooling of molten stainless steel in a controlled environment is essential to prevent cracks or warping as the metal transitions from liquid to solid. This process ensures the structural integrity of the steel and enhances its quality. Cooling molds or crucibles are commonly used during this phase, as they help shape the steel according to specific design requirements while promoting even cooling and minimizing stress on the material.

Handling Solidified Stainless Steel

After cooling is complete, it is crucial to safely remove and handle the solidified stainless steel. Using appropriate tools and equipment, such as tongs or clamps, ensures safety and precision during handling. Once removed, the solidified metal can be cut or processed into usable shapes through machining, grinding, or welding. These methods prepare the steel for its intended application while maintaining its durability and practical utility.

Common Challenges When Melting Stainless Steel

High Melting Temperature

One of the main challenges when melting stainless steel is achieving and maintaining the high temperatures required for the process. Stainless steel typically melts at temperatures between 2,500°F (1,370°C) and 2,750°F (1,510°C), necessitating specialized, robust equipment capable of withstanding extreme heat. Energy demands are high, making efficiency a critical concern in managing operational costs. Equipment that fails to provide consistent heat can lead to uneven melting, potentially compromising the quality of the final product.

Impurities and Oxidation

Controlling impurities and oxidation during the melting process is vital to ensuring the stainless steel’s quality and structural integrity. Exposure to air can cause oxidation, forming unwanted slag layers or weakening the molten steel’s properties. Techniques such as adding flux to bind impurities or using an inert or controlled atmosphere within the furnace help reduce oxidation risks. Proper handling and careful monitoring further ensure the purity and suitability of the finished material.

Applications of Melted Stainless Steel

Industrial Uses of Melted Stainless Steel

Melted stainless steel is a versatile material used across various industries, including construction, automotive, and manufacturing. It is often cast into shapes such as pipes, sheets, and bars to meet specific industrial needs. Additionally, stainless steel is used to produce high-performance components like engine parts, surgical instruments, and industrial equipment, where its durability and resistance to corrosion are critical. Its adaptability makes it an indispensable material in modern infrastructure and technology.

Recycling Stainless Steel

The process of melting scrap stainless steel plays a significant role in producing new products while promoting sustainability. Recycling stainless steel is highly cost-effective, requiring less energy than producing steel from raw materials. Furthermore, recycling minimizes waste and reduces environmental impact by lowering carbon emissions. This closed-loop process ensures that stainless steel remains a key resource in the circular economy and continues to be reused without losing its essential qualities.

When to Seek Professional Help

Industrial-Level Melting

Due to the specialized equipment and conditions required, stainless steel is typically melted in large-scale industrial settings. Industrial furnaces can achieve and maintain the high temperatures necessary for proper melting, which are difficult to replicate in smaller or less controlled environments.

Expertise Required

Handling molten stainless steel requires skilled professionals trained to manage extreme temperatures and ensure strict safety protocols. Their expertise is crucial for monitoring the melting process, managing potential risks, and achieving the desired material quality, making professional involvement essential for successful outcomes.

Conclusion

Understanding “how to melt stainless steel” involves a detailed process that starts with proper preparation and the use of specialized equipment. Safety precautions, such as ensuring ventilation and managing molten metal risks, are critical to protecting workers and maintaining material quality. Every step requires precision and expertise, from handling high temperatures to controlling impurities. The applications of melted stainless steel, ranging from industrial components to recyclable materials, highlight its importance in the modern world. By employing effective techniques and adhering to safety protocols, stainless steel melting plays a vital role in manufacturing and sustainable practices.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.