Preventing electrolysis in copper pipes is crucial for maintaining plumbing system longevity and preventing costly damage.

Electrolysis, caused by stray electrical currents in the plumbing system, accelerates corrosion and can lead to pinhole leaks and pipe failure over time.

This guide explores effective strategies for how to prevent electrolysis in copper pipes, focusing on identifying and mitigating the sources of electrical currents. Methods include installing dielectric unions or isolating sections of piping, which interrupt electrical pathways. Additionally, grounding plumbing systems and ensuring proper bonding techniques can minimize stray currents.

By understanding these preventive measures and their application, homeowners can protect their plumbing infrastructure from electrolysis-related issues. Proactive maintenance and periodic inspections play vital roles in preserving the integrity of copper pipes, ensuring efficient water flow and durability for years to come.

Understanding Electrolysis in Copper Pipes

Electrolysis in copper pipes occurs when electric currents pass through the plumbing system, often due to improper grounding or nearby electrical faults.

This process leads to accelerated corrosion, weakening the metal and eventually causing leaks and pipe failures. The primary culprit behind electrolysis is the presence of dissimilar metals in contact or a grounding issue that allows electrical currents to use the pipes as a pathway.

When copper and another metal, such as steel, are connected in a wet environment, they form a galvanic couple, leading to electrolysis as the metals exchange ions.

Recognizing the signs of electrolysis, such as unexplained wet spots, reduced water pressure, or visible corrosion on pipes, is essential for homeowners to take timely preventive actions.

Understanding the principles behind electrolysis helps in adopting effective mitigation measures, thereby extending the lifespan of copper plumbing systems and preventing costly repairs.

Essential Tools for Preventing Electrolysis in Copper Pipes

To effectively prevent electrolysis in copper pipes, having the right tools on hand is crucial. Below is a list of essential tools that can assist in identifying, mitigating, and repairing issues related to electrolysis:

- Multimeter: For detecting stray electrical currents and potential grounding issues.

- Pipe Wrenches: Useful for tightening and loosening pipe fittings and dielectric unions.

- Dielectric Unions: To separate dissimilar metals and prevent galvanic corrosion.

- Grounding Clamps: Essential for ensuring proper grounding of the plumbing system.

- Pliers: Handy for gripping and manipulating small components.

- Pipe Cutters: For cutting copper pipes to the required length during repairs or installations.

- Inspection Mirror: To help see into hard-to-reach areas and inspect pipes for signs of corrosion.

- Teflon Tape: Used for sealing pipe threads to prevent leaks.

- Wire Brush: For cleaning pipe ends and fittings to ensure good electrical connections.

- Tape Measure: To accurately measure lengths of pipe and distances between fittings.

- Flashlight: A strong, focused light source for illuminating dark or confined spaces during inspections.

Having these tools readily available ensures that homeowners and professionals can address electrolysis issues efficiently and effectively, helping to maintain the integrity and longevity of copper plumbing systems.

10 Methods How to Prevent Electrolysis in Copper Pipes

1. Use Dielectric Unions

One of the most effective methods to prevent electrolysis in copper pipes is the use of dielectric unions. Dielectric unions are specialized fittings designed to separate dissimilar metals, such as copper and galvanized steel, within a plumbing system.

These unions contain a non-conductive barrier that prevents electrical currents from passing between the two metals. By installing dielectric unions wherever dissimilar metals meet, you can significantly reduce the risk of electrolysis and subsequent corrosion. Ensure these unions are properly installed and regularly inspected to maintain their effectiveness.

2. Ensure Proper Grounding

Proper electrical grounding of your plumbing system is essential to prevent electrolysis. Improper grounding can cause stray electrical currents to pass through copper pipes, accelerating corrosion. To ensure proper grounding, have a qualified electrician inspect your home’s electrical system.

They should verify that the grounding connections are secure and that the plumbing system is not inadvertently being used as a grounding path. Installing a grounding rod and connecting it to the electrical panel can help direct stray currents away from the plumbing system, reducing the risk of electrolysis.

3. Install Sacrificial Anodes

Sacrificial anodes are devices made of a more reactive metal, such as magnesium or aluminum, that are installed within the plumbing system to protect copper pipes from electrolysis. These anodes corrode preferentially, thereby protecting the copper pipes.

To install sacrificial anodes, attach them to the copper pipes in strategic locations, such as near water heaters or at the main water supply line. Regularly inspect and replace the anodes as they corrode over time. This proactive approach can significantly extend the lifespan of your copper pipes by diverting corrosive activity away from them.

4. Use Plastic Piping

Replacing metal piping with plastic piping in areas where dissimilar metals are connected can effectively prevent electrolysis. Plastic pipes, such as PVC or PEX, are non-conductive and do not participate in the electrochemical reactions that cause electrolysis.

By using plastic piping for connections between copper and other metals, you can eliminate the risk of electrolysis altogether. Consider using plastic piping for new installations or during renovations to create a more electrolysis-resistant plumbing system.

5. Apply Corrosion Inhibitors

Corrosion inhibitors are chemical compounds that can be added to the water supply to prevent electrolysis and protect copper pipes. These inhibitors form a protective layer on the interior surfaces of the pipes, reducing the metal’s reactivity and slowing down the corrosion process.

To use corrosion inhibitors, consult a water treatment specialist to select the appropriate type and dosage for your plumbing system. Regularly monitor water quality and adjust the inhibitor levels as needed to maintain optimal protection.

6. Maintain Proper Water Chemistry

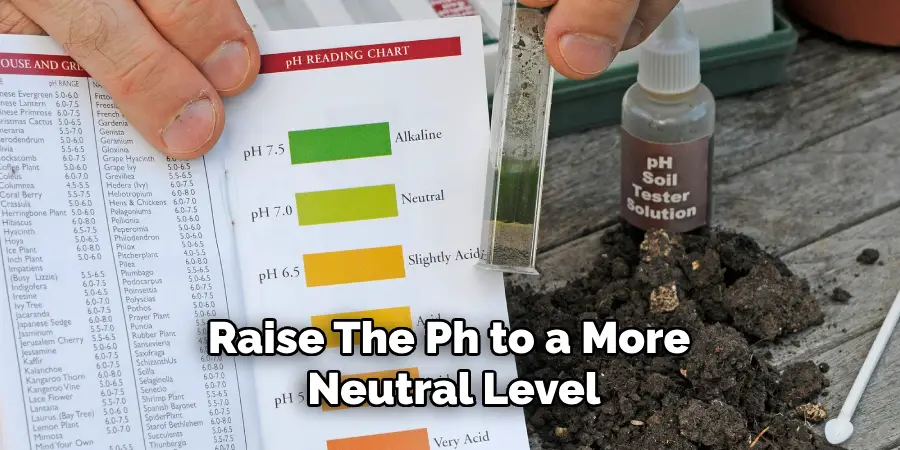

Ensuring the water chemistry in your plumbing system is balanced can help prevent electrolysis. High levels of dissolved oxygen, low pH, or the presence of certain minerals can accelerate corrosion. Regularly test the water for pH, hardness, and mineral content.

If the water is too acidic, consider installing a neutralizing filter to raise the pH to a more neutral level. Additionally, water softeners can be used to reduce the concentration of corrosive minerals. Maintaining proper water chemistry can significantly reduce the risk of electrolysis and prolong the life of copper pipes.

7. Install Insulating Sleeves

Insulating sleeves can be used to physically separate copper pipes from other metal pipes, reducing the risk of electrolysis. These sleeves are made of non-conductive materials, such as rubber or plastic, and are placed over the copper pipes at points where they come into contact with other metals.

By preventing direct metal-to-metal contact, insulating sleeves disrupt the electrochemical pathway needed for electrolysis to occur. This simple and cost-effective solution can be easily implemented during installation or repairs.

8. Use Electrical Isolators

Electrical isolators are devices that can be installed in the plumbing system to prevent electrical currents from traveling through copper pipes.

These isolators are typically placed at strategic points in the system, such as near water heaters or where dissimilar metals are connected.

Electrical isolators work by breaking the electrical continuity of the piping system, thereby preventing electrolysis. Consult with a professional plumber or electrician to determine the best locations for installing electrical isolators in your plumbing system.

9. Regular Inspections and Maintenance

Regular inspections and maintenance of your plumbing system are crucial for preventing electrolysis.

Periodically check all exposed copper pipes for signs of corrosion, such as discoloration, pitting, or leaks. Pay special attention to areas where copper pipes connect to other metals. If you notice any signs of corrosion, take immediate action to address the issue.

Additionally, schedule professional inspections to ensure all preventive measures, such as dielectric unions and sacrificial anodes, are functioning properly. Proactive maintenance can help identify and mitigate potential issues before they escalate.

10. Avoid Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte, such as water.

To prevent galvanic corrosion, ensure that only compatible metals are used together in your plumbing system. For example, avoid connecting copper pipes directly to galvanized steel or brass fittings without a dielectric union or other isolating mechanism.

Additionally, use compatible fittings and connectors that are specifically designed to minimize the risk of galvanic corrosion. Proper material selection and installation practices are key to preventing electrolysis and maintaining a corrosion-resistant plumbing system.

Conclusion

Preventing electrolysis in copper pipes requires a combination of proper installation practices, regular maintenance, and the use of specialized devices and materials.

By employing methods such as using dielectric unions, ensuring proper grounding, installing sacrificial anodes, and maintaining balanced water chemistry, you can effectively reduce the risk of electrolysis and extend the lifespan of your copper pipes.

Regular inspections and proactive maintenance are essential for identifying potential issues early and implementing corrective measures.

By following these ten methods for how to prevent electrolysis in copper pipes, you can protect your plumbing system from the damaging effects of electrolysis, ensuring a durable and reliable water supply for your home.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.