A waffle iron is a versatile kitchen appliance that, when properly cared for, can produce deliciously crispy waffles. Seasoning your waffle iron is an essential step to ensure that waffles don’t stick to the plates and that the appliance maintains a non-stick surface over time. This guide explores the key aspects of how to season a waffle iron. This process involves applying a thin layer of oil to the plates and heating the iron, which creates a protective coating. Whether you have a new iron or want to rejuvenate an old favorite, learning to season it correctly will enhance your breakfast-making experience and prolong the life of the device.

What is Waffle Iron Seasoning?

Waffle iron seasoning refers to the process of creating a protective, non-stick layer on the cooking plates of your waffle iron. This is achieved by applying a thin coat of oil and then heating the iron, allowing the oil to polymerize and form a barrier that prevents waffles from sticking and facilitates easy cleanup. It’s akin to seasoning a cast iron skillet, where the oil bonds to the metal surface, enhancing its non-stick properties over time. Regular seasoning ensures that your waffle iron not only cooks waffles evenly but also retains its performance and longevity.

Why You Should Season Your Waffle Iron

Seasoning your waffle iron is crucial for several reasons, mainly enhancing functionality and extending the appliance’s lifespan. First and foremost, a well-seasoned waffle iron ensures that your waffles release effortlessly, without sticking or tearing, preserving their perfect shape and crisp texture.

This non-stick property also reduces the frustration and mess of having to scrape stuck batter off the plates. Moreover, the seasoning process forms a seal that protects the metal surfaces from moisture and food residue, thus preventing rust and deterioration. By maintaining this protective layer, you also reduce the need for excessive oil or cooking spray, promoting healthier cooking. Regular seasoning ultimately leads to consistent cooking results, making every waffle you make a delightful success.

Tools and Materials Needed

To effectively season your waffle iron, you will need a few basic tools and materials. Begin with a high-quality cooking oil, such as vegetable oil, canola oil, or melted shortening, as these oils have high smoke points and effectively bond to the plates. You’ll also need a clean cloth or paper towels to apply the oil evenly across the surface. A soft brush can help reach into crevices and ensure thorough coverage. Having a heat-proof spatula or wooden spoon on hand can be useful for spreading the oil without risking damage to the iron’s non-stick surface. Lastly, ensure your waffle iron is clean and dry before starting the seasoning process to achieve the best results.

10 Methods on How to Season a Waffle Iron

1. Using a Reciprocating Saw with a Metal Cutting Blade

A reciprocating saw equipped with a bi-metal or carbide-tipped metal cutting blade is one of the most common tools for cutting cast iron pipes. Before starting, secure the pipe firmly to prevent movement. Mark the cut line using a permanent marker or chalk for precision. Apply steady pressure on the saw while cutting to maintain control. Keep the blade cool by occasionally spraying it with water to prevent overheating. This method is relatively quick and versatile but can create significant vibration, so proper stabilization is essential.

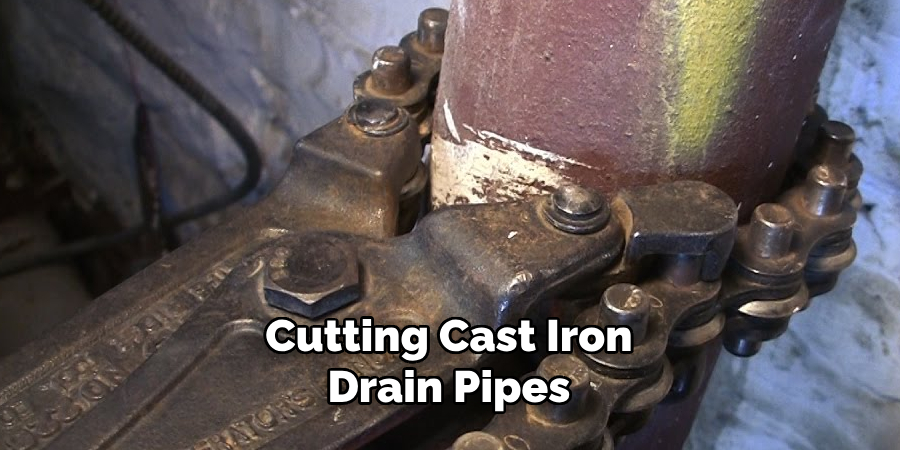

2. Employing a Snap Cutter

A snap cutter, also known as a chain pipe cutter, is designed specifically for cutting cast iron pipes. It consists of a chain with cutting wheels and a ratchet mechanism. Wrap the chain around the pipe at the desired cutting point, and tighten the ratchet to apply pressure evenly. When the pipe eventually snaps, the result is a clean, straight cut. This method is ideal for professional use due to its efficiency but may require practice to achieve perfect results.

3. Using an Angle Grinder

An angle grinder fitted with a diamond blade or metal cutting disc is another effective tool for cutting cast iron. This method works well for small and medium-sized pipes. Start by marking the cut line clearly. Wear safety goggles and gloves to protect against sparks and flying debris. Slowly guide the grinder along the marked line to avoid overheating the blade or damaging the pipe. While angle grinders can make precise cuts, they can also produce significant noise and dust.

4. Cutting with a Hacksaw

For smaller sections of cast iron pipe or tight spaces, a hacksaw with a fine-toothed blade can be used. Although this method is slower and more labor-intensive, it is cost-effective and requires minimal equipment. Secure the pipe to prevent movement, and cut along the marked line with consistent, even strokes. Keep the blade lubricated to reduce friction and prevent wear. This method is ideal for DIY enthusiasts who need a budget-friendly option but is not recommended for larger projects.

5. Using a Rotary Tool

A rotary tool fitted with a reinforced cutting disc can be used for precise cuts on thinner cast iron pipes. This method is excellent for detail work or cutting pipes in confined spaces. Mark the cutting line clearly and wear safety gear to protect against sparks and debris. Work slowly to maintain control and prevent the cutting disc from breaking. Rotary tools are versatile and accessible but may not be suitable for cutting thicker pipes.

6. Employing a Plasma Cutter

A plasma cutter uses high-temperature plasma to slice through metals, including cast iron. This tool offers unparalleled precision and speed, making it an excellent choice for professionals. Mark the cut line clearly and set the plasma cutter to the appropriate settings for cast iron. Ensure proper ventilation, as this method produces fumes. While plasma cutters are highly effective, they are also expensive and require expertise to operate safely.

7. Using a Grinder and Chisel Combination

For situations where precision tools are unavailable, a grinder and chisel combination can be used. Start by scoring the pipe along the marked line using a grinder with a diamond blade. Once the groove is deep enough, place a cold chisel in the groove and tap it with a hammer to break the pipe along the score line. This method requires patience and a steady hand but can be effective for rough cuts in cast iron.

8. Cutting with an Oxy-Acetylene Torch

An oxy-acetylene torch can be used to cut through cast iron pipes with heat. This method is fast and efficient but requires careful handling to avoid overheating or warping the pipe. Mark the cutting line and adjust the torch to produce a focused flame. Work slowly along the marked line, allowing the heat to melt through the material. This method is suitable for professional use but should only be performed in well-ventilated areas with proper safety gear.

9. Using a Pipe Cutter Tool

Specialized pipe cutters designed for metal pipes can be used for cutting cast iron. These tools feature adjustable cutting wheels that score the pipe as they are rotated around it. Gradually tighten the tool after each rotation to deepen the cut. Once the pipe is sufficiently weakened, it will break cleanly. This method is straightforward and produces minimal debris but may take longer than power tools.

10. Utilizing a Circular Saw with a Metal Cutting Blade

A circular saw equipped with a diamond or carbide-tipped blade can cut cast iron pipes quickly and efficiently. Mark the cut line clearly and secure the pipe in place. Guide the saw along the line with steady pressure, taking care to avoid kickback. Use water to cool the blade and minimize dust. This method is ideal for straight cuts on larger pipes but requires skill to operate safely.

Common Mistakes to Avoid

When cutting cast iron drain pipes, it is crucial to minimize errors to ensure a smooth and effective process. One common mistake is failing to secure the pipe adequately before cutting. Movement during cutting can lead to uneven cuts and potential injury. Another mistake is using the wrong type of blade or tool, which can result in inefficiency or even damage to the pipe. Additionally,

not wearing appropriate safety gear, such as gloves and goggles, can pose significant risks from flying debris or sparks. Overheating the cutting tool is also common and can be prevented by using water or cutting oil to cool the blade. Lastly, rushing the process can lead to mistakes; patience and precision are key to achieving a clean cut without compromising safety or quality.

Conclusion

Cutting cast iron drain pipes can be accomplished using a variety of methods, each with its own set of advantages and challenges. From versatile power tools like reciprocating saws and angle grinders to specialized devices such as snap cutters and plasma cutters, there’s a method suitable for different project scales and skill levels. When selecting the appropriate technique, consider factors like the pipe’s size and thickness, the work environment, and your own expertise with the tools. Thanks for reading, and we hope this has given you some inspiration on how to season a waffle iron!

you can also check it out to Clean Sticky Cast Iron Skillet

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.