Maintaining the efficiency of your lawn edger begins with keeping its blade sharp. A sharp blade ensures cleaner cuts, which not only improves the appearance of your lawn but also promotes healthier grass growth. Over time, edger blades can become dull due to contact with soil, rocks, and other debris.

This guide will walk you through how to sharpen an edger blade, helping you achieve a perfectly manicured lawn with minimal effort.

Importance of Regular Maintenance

Regular maintenance of your lawn edger is crucial for several reasons. Firstly, it ensures optimal performance by keeping the machine running smoothly and efficiently, which in turn reduces the strain on the motor and extends its lifespan. Consistent maintenance also helps prevent unexpected breakdowns or costly repairs, saving both time and money in the long run.

Moreover, a well-maintained edger blade produces cleaner and more precise cuts, which not only enhances the aesthetics of your lawn but also promotes the overall health of the grass by minimizing damage and stress. Regular upkeep, including cleaning, inspecting, and sharpening the blade, ensures that your lawn edger remains a reliable tool in achieving a pristine landscape.

Tools and Materials Needed

To sharpen an edger blade efficiently, you’ll need a few essential tools and materials. Start by gathering a wrench or socket set to remove the blade from the edger. You’ll also need a bench vise to securely hold the blade in place during sharpening.

For the sharpening process itself, a metal file or an angle grinder with a grinding disc is required. It’s also crucial to have safety gear, including safety goggles and gloves, to protect yourself from metal shavings and sharp edges. Lastly, keep a clean cloth or brush on hand for cleaning the blade before and after sharpening, as well as a can of lubricant to prevent rust once the sharpening is complete.

Safety Precautions

Before you begin sharpening your edger blade, it’s essential to prioritize safety to prevent accidents or injuries. Start by ensuring that the edger is turned off and unplugged to eliminate any risk of the machine starting unexpectedly during the maintenance process. Wear safety goggles to protect your eyes from flying metal shavings and gloves to safeguard your hands from sharp blade edges.

Make sure your workspace is well-lit and free from clutter to avoid tripping hazards. If you’re using an angle grinder, follow the manufacturer’s instructions carefully and maintain a firm, steady grip on the tool. Always check that all tools and equipment are in good working condition before starting, and never force any equipment if it doesn’t fit or function as expected. Taking these precautions seriously will help ensure a smooth and safe sharpening process.

10 Methods How to Sharpen an Edger Blade

1. Assess the Blade’s Condition

The first step in sharpening an edger blade is to evaluate its current state. Remove the blade from the edger and inspect it for dullness, nicks, or significant wear. A blade with minor dullness or small chips can be sharpened, but one that is severely damaged or corroded may need to be replaced.

Assessing the condition ensures you use the right sharpening technique and avoid wasting time on a blade that is beyond repair.

2. Gather the Necessary Tools

Sharpening an edger blade requires the right tools for the job. Common items include a wrench or socket set to remove the blade, a metal file, a bench grinder, or a sharpening stone. Additional tools, such as a clamp, safety goggles, gloves, and a wire brush, are essential for safety and precision. Having all tools ready ensures a smooth and efficient sharpening process.

3. Disconnect the Power Supply

For safety, disconnect the edger from its power source before removing the blade. If you have a gas-powered edger, disconnect the spark plug wire to prevent accidental starts. For electric models, unplug the machine or remove the battery. Taking this precaution eliminates the risk of injury during the blade removal and sharpening process.

4. Remove the Blade Safely

Use a wrench or socket set to loosen and remove the bolts securing the blade to the edger. Hold the blade steady with a block of wood or wear sturdy gloves to prevent it from spinning as you loosen the bolts. Note the orientation of the blade to ensure it is reattached correctly after sharpening. Proper removal minimizes the risk of damaging the blade or the edger.

5. Clean the Blade Thoroughly

Before sharpening, clean the blade to remove dirt, grass, and rust that can interfere with the sharpening process. Use a wire brush or steel wool to scrub the blade’s surface, paying particular attention to the edges. For stubborn rust, soak the blade in a vinegar solution or apply a rust remover. A clean blade allows for a smoother sharpening process and ensures a consistent edge.

6. Sharpen with a Metal File

A metal file is a simple and effective tool for sharpening an edger blade. Secure the blade in a clamp or vice to hold it steady. Position the file at the same angle as the blade’s beveled edge and make long, even strokes away from your body. Repeat this motion until the edge is sharp, checking the angle regularly to maintain consistency. This method is ideal for those without access to power tools.

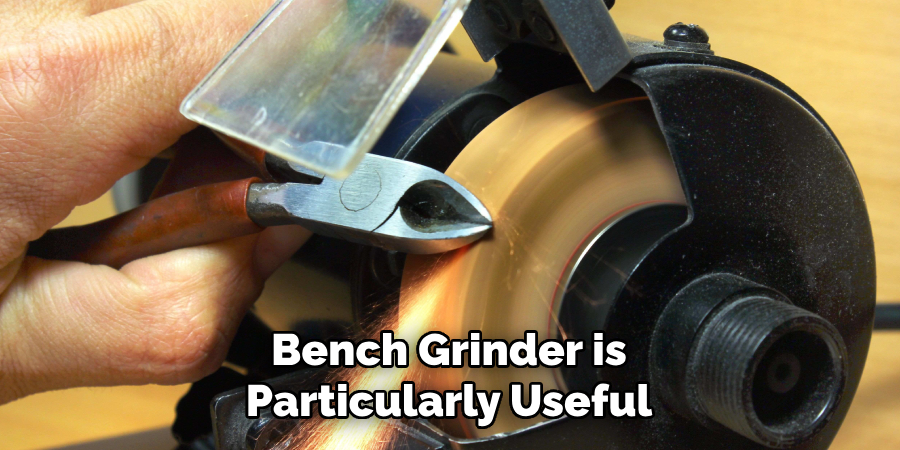

7. Use a Bench Grinder for Precision

For faster and more precise sharpening, use a bench grinder. Secure the blade and align the beveled edge with the grinder’s wheel. Apply light, even pressure to avoid overheating the blade, which can weaken the metal. Dip the blade in water periodically to keep it cool. A bench grinder is particularly useful for heavily dulled or chipped blades, as it removes material quickly and efficiently.

8. Sharpen with a Sharpening Stone

A sharpening stone offers a more controlled, manual approach to sharpening an edger blade. Place the stone on a stable surface and hold the blade at the correct angle.

Move the blade back and forth across the stone, maintaining even pressure. Use a lubricating oil or water on the stone to reduce friction and achieve a smoother edge. This method is ideal for those seeking a precise, fine edge on their blade.

9. Balance the Blade After Sharpening

After sharpening, it’s crucial to balance the blade to prevent vibrations and uneven wear during operation. Use a blade balancer or hang the blade on a nail to check for balance. If one side dips lower, file or grind the heavier side until the blade is balanced. A well-balanced blade ensures smoother operation and reduces strain on the edger’s motor.

10. Reattach the Blade and Test the Edger

Reattach the blade to the edger, ensuring it is securely fastened with the bolts. Double-check the orientation to ensure the sharp edge faces the cutting direction.

Reconnect the power supply or spark plug wire, and test the edger on a small section of grass or dirt. Observe the performance to confirm the blade cuts cleanly and smoothly. If necessary, repeat the sharpening process for optimal results.

Tips for Achieving the Best Sharpening Results

To achieve optimal sharpening results for your edger blade, consider the following tips:

- Choose the Right Angle: Maintaining the correct sharpening angle is crucial for an efficient cutting edge. Follow the manufacturer’s specifications or the existing bevel on the blade to ensure precision.

- Use Consistent Strokes: Whether you’re using a file, grinder, or sharpening stone, make sure your strokes are even and consistent. This practice prevents uneven edges and enhances cutting performance.

- Maintain Cool Temperature: Overheating can weaken the metal, so always allow the blade to cool down. Using water or oil as a coolant during sharpening can help regulate the temperature.

- Inspect the Blade Regularly: Periodically check the blade for any signs of wear or damage. Addressing small issues before they worsen will help prolong the blade’s lifespan.

- Keep Tools in Good Condition: Regularly inspect and maintain your sharpening tools. Clean and store them properly to ensure they function well and provide accurate results.

Implementing these tips will help ensure that your edger blade is sharp, balanced, and ready for effective performance.

Common Mistakes to Avoid

When sharpening an edger blade, there are several common mistakes that can compromise the blade’s performance and longevity. First, avoid using excessive force or pressure, which can damage the blade and lead to an uneven edge. It’s important to apply light, controlled strokes regardless of the tool you use. Another common mistake is neglecting to balance the blade after sharpening.

An unbalanced blade can lead to vibrations and uneven cuts, placing strain on the edger’s motor. Additionally, overlooking the importance of maintaining the proper angle during sharpening can result in a poorly performing cutting edge. Ensure you follow the existing bevel or manufacturer’s guidelines for optimal results.

Conclusion

Properly sharpening and maintaining your edger blade is essential for achieving clean and efficient cutting results. With regular care, including cleaning, precise sharpening, and careful balancing, you can extend the blade’s lifespan and enhance the performance of your edger.

By avoiding common mistakes such as applying excessive force, neglecting balance, or using an incorrect angle, you ensure not only a sharp blade but also safe and smooth operation. So, there you have it – a quick and easy guide on how to sharpen an edger blade.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.