In the culinary world, the sharpness of a knife can make a significant difference in both the efficiency and quality of food preparation.

Keeping a carbon steel knife sharp is crucial not only for precise and clean cuts but also for ensuring safety in the kitchen, as a dull blade can easily slip and cause injuries. A sharp knife enhances your cooking experience, allowing you to slice through ingredients with minimal effort and preserving the integrity of the food. Knowing how to sharpen carbon steel knife is a valuable skill that ensures your knife remains in optimal condition.

The sharpening process involves selecting the appropriate tools, preparing the sharpening stone, and following a systematic approach to refine and hone the knife’s edge. By investing time and effort into maintaining your carbon steel knife, you will enjoy better performance and extend the longevity of this indispensable kitchen tool.

Understanding Carbon Steel Knives

Carbon steel knives are renowned for their exceptional sharpness and edge retention, which sets them apart from their stainless steel counterparts.

Unlike stainless steel, carbon steel contains a higher percentage of carbon, contributing to its hardness and ability to achieve a finer, sharper edge. However, this increased hardness also makes carbon steel more prone to chipping if improperly handled. While stainless steel knives are more resistant to rust and corrosion, carbon steel knives require diligent maintenance to prevent discoloration and rusting.

One of the primary advantages of carbon steel knives is their ease of sharpening. Carbon steel’s softer yet sturdy composition allows for quick and efficient sharpening, making it easier to maintain a razor-sharp edge with regular honing and sharpening sessions. On the downside, carbon steel knives can develop a patina over time, which, while providing some protection against rust, may be considered unaesthetic by some users.

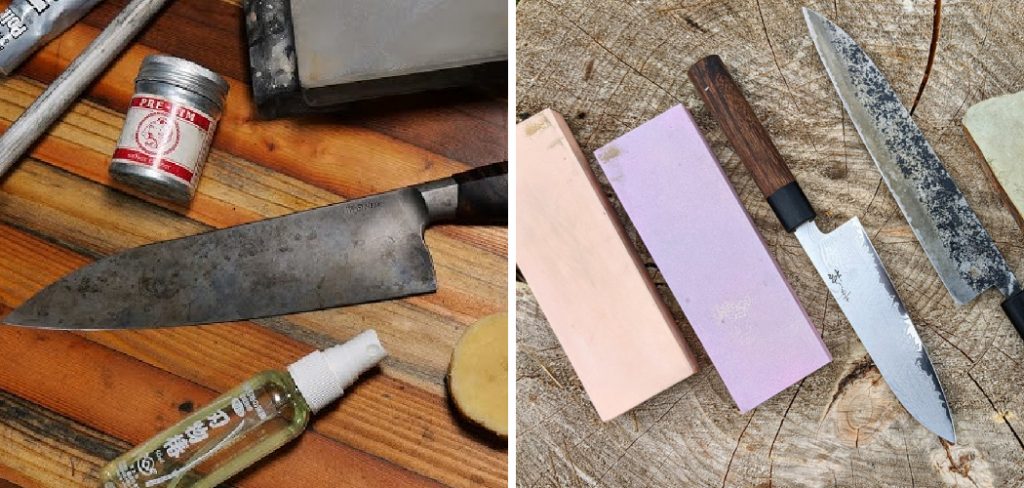

Regular maintenance is crucial for carbon steel knives to preserve their performance and longevity. This includes thoroughly drying the knife after each use, applying a light coat of oil to prevent rust, and scheduling consistent sharpening sessions to keep the blade in prime condition. By understanding carbon steel knives’ unique characteristics and care requirements, you can maximize their benefits and enjoy superior performance in your culinary tasks.

Tools Needed for Sharpening

When it comes to sharpening a carbon steel knife, having the right tools is essential for achieving a razor-sharp edge. You will need a sharpening stone (also known as a whetstone), a honing rod, or a sharpening system. Each tool has its specific function, and understanding how to use it will ensure your knife remains in peak condition.

A sharpening stone is a must-have for serious knife maintenance. These stones come in various grit levels, typically categorized as coarse, medium, and fine. Coarse grit stones (ranging from 200 to 600 grit) are ideal for repairing chipped or extremely dull blades. Medium grit stones (800 to 2000 grit) are used for regular sharpening, while fine grit stones (3000 to 8000 grit) are perfect for achieving a polished, razor-sharp edge. Depending on your knife’s condition, you may need to use multiple stones in succession to attain the best results.

In addition to sharpening stones, honing rods is important for daily maintenance as it helps realign the blade’s edge without removing much material. Regular honing can extend the time between full sharpening sessions.

Sharpening systems and electric sharpeners offer an alternative for those who prefer more guided methods. These systems often come with built-in angle guides and multiple grit options, making them easier and faster to use, though they may lack the precision of a traditional whetstone.

Optional tools that can enhance your sharpening experience include sharpening oil or water, which lubricates the stone and removes metal particles, a cloth for wiping down the blade, and safety gloves to protect your hands during the process. Being equipped with the right tools ensures that you can properly sharpen your carbon steel knife, maintaining its performance and longevity.

Preparing the Sharpening Stone

Proper preparation of the sharpening stone is crucial in ensuring the effective sharpening of your carbon steel knife. The first consideration is choosing the right grit based on the knife’s current condition. If your knife has nicks or is extremely dull, start with a coarse stone (200 to 600 grit). A medium-grit stone (800 to 2000 grit) will suffice for routine sharpening. A fine-grit stone (3000 to 8000 grit) is ideal for finishing touches and achieving a razor-sharp edge. Using the correct grit will help you avoid unnecessary wear and tear on both the knife and the stone.

Depending on the type of whetstone you have, you will need to either soak it in water or apply oil. Water stones should be submerged in water for about 10 to 15 minutes until bubbles stop emerging, indicating they are fully saturated. This lubrication helps to create a slurry that aids in the sharpening process. On the other hand, oil stones require a few drops of sharpening oil to be evenly applied across the surface. The oil acts as a lubricant, preventing metal particles from clogging the stone, ensuring a smoother sharpening experience.

Once the stone is ready, set up a stable sharpening station. This often involves placing a non-slip mat or towel beneath the stone to keep it secure and prevent it from sliding during use. Some sharpening stones come with a base or holder to provide additional stability. Ensuring that your sharpening station is stable improves the consistency of your strokes and enhances safety, reducing the risk of accidental injuries. Proper preparation sets the foundation for a successful sharpening session, ensuring your carbon steel knife is refined to its sharpest potential.

How to Sharpen Carbon Steel Knife: Using a Whetstone

Sharpening your carbon steel knife with a whetstone is a methodical process that begins with positioning the knife at the correct angle. Typically, a 20-degree angle is most effective for kitchen knives, balancing sharpness with durability. To achieve this angle, imagine splitting the 90-degree corner between the blade and the stone into half (45 degrees), then half again (22.5 degrees), and finally adjusting slightly lower to reach approximately 20 degrees.

If your blade is dull or damaged, start the sharpening process with the coarse grit stone (200 to 600 grit). Place the knife at the chosen angle and apply even pressure as you move it across the stone sweepingly, from the heel to the tip. This motion ensures that the entire blade surface makes contact with the stone. Consistency is crucial, so try to maintain the same pressure and angle throughout each stroke.

Continue this process on both sides of the blade until you feel a burr – a small, wire-like edge – forming along the knife’s length. The burr signifies that you have sharpened the edge sufficiently and can now progress to finer grits for refining and polishing.

Switch to a medium grit stone (800 to 2000 grit) and repeat the same sharpening motion, applying less pressure. Finish with the fine grit stone (3000 to 8000 grit) for the final touches, ensuring a razor-sharp and polished edge. Throughout the process, periodically check the blade’s sharpness and maintain even strokes. Following these steps will ensure that your carbon steel knife achieves an exceptionally sharp and durable edge, enhancing your culinary precision and efficiency.

How to Sharpen Carbon Steel Knife: Using an Honing Rod

Difference Between Honing and Sharpening

Understanding the distinction between honing and sharpening is essential for maintaining your carbon steel knife. Sharpening involves removing material from the blade to create a new edge, typically performed with a whetstone or sharpener. In contrast, honing realigns the knife’s edge, correcting any bends or deformations without grinding away significant metal. Honing does not make a dull knife sharp but maintains the edge between sharpening sessions.

Proper Technique for Using an Honing Rod

Hold the honing rod vertically to hone your knife properly, placing its tip on a stable surface, such as a cutting board. With moderate pressure, position the knife at a 20-degree angle against the rod’s steel, starting at the base of the blade (heel). Draw the knife downwards and towards you, ensuring the edge matches the rod’s entire length, from heel to tip. Repeat this motion on the other side of the blade to maintain a balanced edge. Typically, five to ten strokes per side are sufficient.

Frequency of Honing Versus Sharpening

Honing should be done regularly, preferably before or after each use, to keep the knife’s edge aligned and in optimal condition. In comparison, sharpening is required less frequently, often every few months, or when the knife becomes noticeably dull. Regular honing minimizes the need for sharpening, prolonging the blade’s lifespan and enhancing its performance in the kitchen.

Sharpening Systems and Alternatives

Overview of Guided Sharpening Systems and Electric Sharpeners

Guided sharpening systems and electric sharpeners offer convenient alternatives to the traditional whetstone method. Guided sharpening systems typically consist of a frame that holds the knife at a consistent angle while you move it across a series of abrasive surfaces. This eliminates the guesswork involved in maintaining the correct sharpening angle. Electric sharpeners automate the sharpening process even further, drawing the blade through motorized abrasive disks to create a sharp edge with minimal effort.

Pros and Cons of Using These Systems Compared to Traditional Methods

Guided sharpening systems are highly consistent and user-friendly, making them ideal for beginners and those seeking precision. However, they can be more time-consuming than electric sharpeners and often come at a higher cost. Electric sharpeners, on the other hand, are quick and easy to use, making them perfect for busy kitchens. The downside is that they can remove more metal than necessary, potentially shortening the knife’s lifespan and offering less control over the sharpening process than manual methods.

Tips for Choosing the Right Sharpening System for Your Needs

When selecting a sharpening system, consider your skill level, the types of knives you own, and how often you need to sharpen them. Beginners or those with limited time may prefer the simplicity of electric sharpeners, while avid home cooks and professionals might opt for guided systems for greater control and precision. Always choose a system that matches your specific needs to ensure your knives remain in top condition.

Testing the Sharpness

Methods to Test the Sharpness of the Knife

To ensure your carbon steel knife is properly sharpened, several reliable methods exist for testing its sharpness. The paper test involves slicing through a sheet of paper; a sharp knife should glide through effortlessly without snagging. Another method is the tomato test, where you try to slice a ripe tomato with minimal pressure; a sharp blade will cut cleanly without squishing the fruit.

Signs of a Properly Sharpened Knife

A properly sharpened knife will have a smooth, polished edge that can easily glide through various materials with minimal resistance. It should also feel balanced in hand, with no rough or jagged spots along the blade.

Making Adjustments if the Knife is Not Sharp Enough

If your knife does not pass these sharpness tests, it may require additional honing or sharpening. Return to the whetstone or honing rod, paying extra attention to maintaining the correct angle and consistent pressure to achieve the desired sharpness.

Maintenance and Care

Proper maintenance and care are paramount for preserving the quality and longevity of your carbon steel knife. Regular cleaning and thorough drying after each use are essential to prevent rust and corrosion. Hand wash the knife with mild soap and warm water, then dry it immediately with a soft cloth. Avoid soaking or putting the knife in a dishwasher, as this can cause damage and increase the risk of rust.

Proper knife storage is equally important. Use a knife block, magnetic strip, or blade guard to protect the blade and edge from damage. Ensure the knife is stored in a dry environment to prevent moisture-related issues.

Maintaining sharpness between sharpening sessions is also crucial. Regularly honing the knife before or after each use realigns the edge and keeps it razor-sharp. By following these maintenance and care tips, you can ensure your carbon steel knife remains a reliable and efficient tool in your kitchen for years to come.

Conclusion

Understanding how to sharpen carbon steel knife is essential for any home cook or professional chef aiming for optimal performance in the kitchen. The process involves key steps such as using a whetstone or guided sharpening system, regularly honing to maintain the edge and testing the sharpness to ensure effectiveness. Consistent maintenance, including proper cleaning and correct storage, prolongs the knife’s lifespan and prevents deterioration.

The emphasis on regular maintenance and proper technique cannot be overstated, as they contribute significantly to the knife’s overall performance and durability. Investing time in sharpening your knife enhances your cooking experience and ensures safety and precision in food preparation. By mastering these techniques and committing to regular upkeep, you will keep your carbon steel knife in top condition, making it a reliable and indispensable tool in your culinary arsenal.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.