If you’ve ever taken on a DIY project involving cutting, threading, or working with hardened steel, you know just how frustrating it can be. This tough metal seems impervious to regular drills and taps. You strain and struggle just trying to make a basic hole, feeling like you’re getting nowhere.

The tap bites in for a split second, then immediately becomes dull again, to the point where you question if hardened steel can even be machined at all. Well, have no fear. Hardened steel may be tough, but it’s far from impossible to work with once you know the right techniques. In this blog post, we will provide you with a detailed guide on how to tap hardened steel.

Can You Tap Hardened Steel?

Have you ever tried to tap hardened steel? It can be quite a challenge. Hardened steel, as the name suggests, is incredibly tough and deformation-resistant. This makes it popular for industrial machinery, tools, and even knives. However, tapping it can be a tricky feat.

You need a high-quality tap and plenty of patience to get the job done. The process involves applying pressure and rotating the tap to create threads on the metal surface. While it may be difficult, it’s not impossible. You can tap hardened steel like a pro with some practice and determination.

Why Should You Tap Hardened Steel?

Hardened steel is one of the toughest, most durable materials out there. So why on earth should you tap it? Well, despite its reputation, hardened steel can be tapped with the right tools and techniques.

And if you’re working with this material, tapping can be a great way to create threaded holes for screws, bolts, and other fasteners. Of course, tapping hardened steel isn’t easy – it requires precision, patience, and a lot of care. But if you’re up for the challenge, the results can be incredibly rewarding. So next time you’re faced with the prospect of tapping hardened steel, don’t shy away – embrace the opportunity to master this tough-as-nails material!

A Detailed Guide on How to Tap Hardened Steel

1. Choose the Right Tool

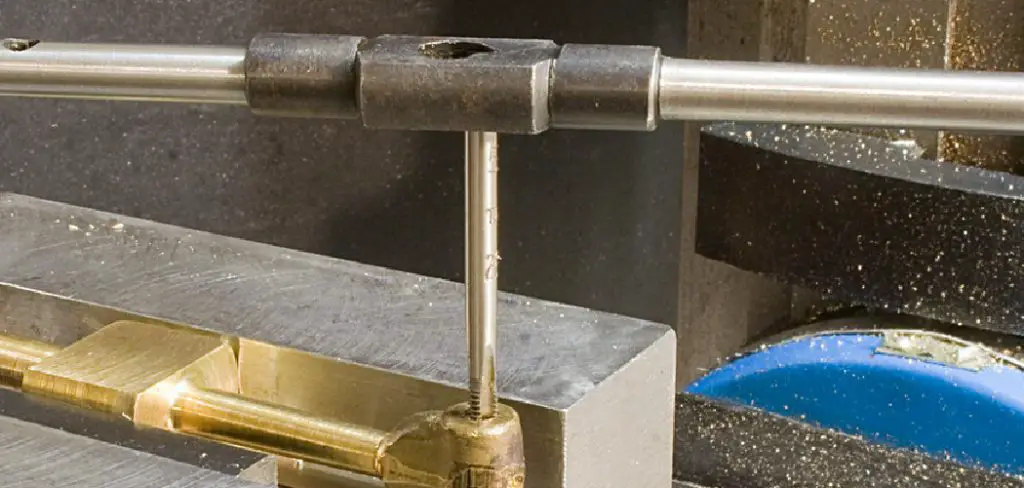

The first step to tapping hardened steel is choosing the right tool. You will need a high-speed steel (HSS) tap designed for hard metals. These taps have a more significant number of flutes and a higher helix angle. They are also made of cobalt, making them more durable. You may also need a high-quality tap handle to effectively tap the hardened steel.

2. Proper Preparation

Hardened steel has a high resistance to deformation, making it challenging to tap. Proper preparation is critical to ensure a successful tap. First, clean the material’s surface to remove any debris or oil that may cause the tap to slip or break. Next, use a center punch to create a starting point for the tap. This will help prevent the tap from wandering and ensure a more precise hole.

3. Lubrication

Hardened steel requires adequate lubrication during the tapping process. A high-quality tapping fluid is essential to reduce friction, which can cause the tap to break. It’s crucial to apply the lubricant frequently during the tapping process to ensure the tap doesn’t overheat, which can cause it to wear out quickly.

4. Start Slowly

Tapping hardened steel requires patience and precision. Start the tapping process slowly to prevent the tap from breaking or the threads from becoming damaged. Monitor the tapping process frequently to ensure the tap is not overheating, which can cause it to break. Go slow, and be gentle with the tap. This will ensure that the threads come out clean and precise.

5. Clean and Polish

Cleaning and polishing the threads is essential once you have successfully tapped the hardened steel. Use a thread chaser to remove any debris or chips remaining in the threads. You can then use a wire brush to polish the threads and remove any burrs. This will ensure smooth threading and eliminate any risk of the threads binding together.

6. Use a Thread Locker

To ensure the threads stay in place and do not loosen over time, it’s crucial to use a thread locker. This adhesive is specifically designed for metal-to-metal connections and will help secure the threads in place. Be sure to choose a thread locker that is suitable for hardened steel.

7. Practice Makes Perfect

Tapping hardened steel may take some practice to perfect. It’s essential to have patience and not rush the process. If you are new to tapping, practicing on a scrap piece of hardened steel before attempting to tap a critical part or project is best. This will help you gain confidence and ensure your tapping skills are up to par.

5 Considerations Things When You Need to Tap Hardened Steel

1. Tool Selection

When tapping hardened steel, selecting the right tool for the job is important. The type of tap you use will depend on the material and size of the hole being tapped. High-speed steel (HSS) taps are typically used for softer materials such as aluminum, while carbide-tipped taps are better suited for harder materials such as hardened steel. It’s also important to make sure your drill and tap are compatible with each other.

2. Lubrication

Lubrication is key when tapping hardened steel, as it helps to reduce friction and heat buildup that can lead to broken tools or damaged parts. High-quality cutting oil should be used when drilling and tapping hardened steel to ensure optimal performance and extend the life of your tools. It’s also important to make sure the lubricant is compatible with the material you are working with.

3. Drill Speed

The speed at which you drill into hardened steel is important as it affects both the quality of the hole being drilled and the life of your tools. When drilling into hardened steel, it’s best to start slowly and gradually increase until you reach an optimal drilling speed for your particular application. This will help ensure that you get a clean, accurate hole without putting too much strain on your tools or damaging the material being drilled into.

4. Tap Feed Rate

The feed rate at which you tap into hardened steel is just as important as drill speed when getting a good result without damaging your tools or material being tapped into. Generally speaking, a slower feed rate is better when tapping into harder materials such as hardened steel, so don’t rush through this process, as doing so could cause damage or breakage to your tools.

5. Coolant

Using coolant when tapping hardened steel can help reduce friction between your tools and material, resulting in smoother cuts and reducing wear on both your tools and the material being tapped into. Coolants come in many forms, including water-soluble oils, semi-synthetic fluids, synthetic fluids, oil/water emulsions, aerosols, etc., so select one that works best for your application requirements. It’s also important to properly apply and monitor the coolant during the tapping process to ensure optimal performance.

By following these considerations, you can successfully tap hardened steel without causing damage or breakage to your tools or material. Remember to always choose the right tool for the job, use proper lubrication and coolant, and carefully control drilling and tapping speeds to achieve the best results.

Benefits of Tap-Hardened Steel

Tap-hardened steel is a material that has been heat-treated to increase its hardness and strength. The benefits of using this type of steel are many and varied. One of the most significant advantages is its resistance to wear and tear, which makes it ideal for use in machinery and other heavy-duty applications. It is also more durable than other types of steel and can withstand high levels of stress and pressure.

Additionally, tap-hardened steel is more resistant to corrosion and rust than other metals, making it suitable for harsh environments. These properties and its versatility make it an excellent choice for a wide range of industries and applications. Whether you are seeking a more durable, cost-effective material for your product or a more robust solution for your machinery, tap-hardened steel is a superior choice.

Some Common Mistakes People Make When Trying to Tap Hardened Steel

Working with hardened steel can be a challenging and frustrating task, especially when trying to tap it. While it may seem simple at first, many people make common mistakes that can result in broken tools or damaged materials. One of the most frequent missteps is using the wrong tapping tool for the job. It is crucial to use a tool specifically designed for hardened steel and to choose the correct size and thread type for your project.

Additionally, failing to lubricate the surface properly can also cause issues. Using high-quality cutting oil can help prolong the life of your tools and preserve the integrity of the material being tapped. It may seem like a small detail, but taking the time to choose the right tool and properly lubricate your work surface can make all the difference in the success of your project.

Conclusion

Tapping hardened steel requires patience, precision, and the right tools. You can successfully tap hardened steel with the proper preparation, lubrication, and techniques. Always choose high-speed steel (HSS) taps designed for hard metals. Ensure proper preparation and lubrication, and start slowly. Lastly, clean and polish the threads to ensure smooth threading. If you follow these steps, you will have no trouble tapping that hardened steel. Thanks for reading our post about how to tap hardened steel.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.