Galvanized steel is steel that has been coated with a layer of zinc to protect it from corrosion and rust. This coating is applied through various methods, including hot-dip galvanizing and electro-galvanizing, offering a robust shield against the elements.

Common uses for galvanized steel include construction materials, automotive parts, and outdoor structures such as fences or railings, where durability and longevity are essential.

Identifying whether steel is galvanized is crucial for applications requiring enhanced corrosion resistance, ensuring the material will withstand environmental exposure.

To understand how to tell if steel is galvanized, several methods can be employed, such as visual inspection, magnetic testing, scratch testing, chemical tests, and conductivity tests.

Accurately identifying galvanized steel ensures optimal performance and safety in its intended use, making these methods valuable tools in both industrial and residential settings.

How to Tell if Steel Is Galvanized: Visual Inspection

Surface Appearance

Galvanized steel is often recognizable by its distinctive matte gray finish, which is typically adorned with a spangled pattern. This spangled appearance is due to the crystallization of zinc during the cooling process, resulting in a unique, slightly textured surface.

The surface appearance can vary depending on the method used for galvanization. Hot-dip galvanized steel generally has a rougher, more irregular coating as it is immersed in molten zinc, causing a thicker, more rugged layer to form.

In contrast, electro-galvanized steel, subjected to an electric zinc deposition process, boasts a smoother and thinner coating, making it more uniform and less textured than its hot-dip counterpart.

When performing a visual inspection, one should also be alert to any signs of the zinc coating flaking off or the presence of white rust, which is actually zinc oxide. White rust can indicate that the galvanization is beginning to break down, usually due to prolonged exposure to moisture without adequate airflow.

This early-stage corrosion can be a vital clue in identifying whether steel has been galvanized.

Comparison with Non-Galvanized Steel

Bare steel, lacking any protective zinc coating, has a significantly different appearance compared to galvanized steel.

It typically presents a shinier, more polished surface but is much more vulnerable to the elements. Rust formation can often be observed on non-galvanized steel, manifesting as reddish-brown spots that gradually spread and intensify over time.

In contrast, galvanized steel’s corrosion resistance means it shows fewer signs of rust, even after extended exposure. Thus, inspecting for rust can serve as a helpful tip when trying to distinguish between the two.

Bare areas that develop rust quickly are indicative of non-galvanized steel. In contrast, galvanized steel, with its zinc coating, is far more likely to remain rust-free longer, maintaining its matte gray appearance despite environmental challenges.

How to Tell if Steel Is Galvanized: Magnetic Test

Conducting the Magnetic Test

The magnetic test is a simple and effective method for determining whether steel is galvanized. This test capitalizes on steel’s inherent magnetic properties, which remain unaffected by the zinc coating applied during the galvanization process.

- Step-by-step Instructions for Performing the Test:

- Obtain a Magnet: A standard magnet will suffice for this test. Ensure that the magnet is strong enough to adhere to the steel’s surface easily.

- Place the Magnet on the Steel Surface: Gently place or attach the magnet to the steel area you are testing. Ensure contact is made between the magnet and the steel.

Expected Results

- Understanding the Results:

- When the magnet is placed on the steel surface, it should adhere firmly, irrespective of whether the steel is galvanized or not.

- The zinc coating applied during the galvanization process does not alter the steel’s magnetic properties.

- Galvanized Steel: Since the underlying material in galvanized steel is still steel—which is magnetic—the magnet will stick to the surface as it would with non-galvanized steel. The presence of the zinc coating does not interfere with the magnetic test as the magnet responds to the steel beneath the coating.

- Non-Galvanized Steel: The magnet will also adhere strongly to non-galvanized steel due to the same innate magnetic properties.

It is essential to note that while the magnetic test confirms the presence of steel, it does not exclusively distinguish between galvanized and non-galvanized steel.

However, when used in conjunction with other methods such as visual inspection and conductivity tests, it can effectively contribute to identifying galvanized steel.

This non-destructive and straightforward test is especially useful for quick assessments and preliminary inspections when detailed laboratory testing is not feasible.

Scratch Test

Preparing for the Scratch Test

Conducting a scratch test is another effective way to determine if steel is galvanized. The following preparations are essential for an accurate test:

- Necessary Tools: For this test, you will need a file or sandpaper. Both tools can lightly abrade the steel surface for inspection.

- Testing Area: Perform the test on an inconspicuous area of the steel to avoid damaging the visible surface. This practice ensures that any scratches or marks made will not detract from the overall appearance of the steel product.

Performing the Scratch Test

To conduct the scratch test, follow these step-by-step instructions:

- Lightly Scratch the Surface: Take your file or sandpaper and gently scratch the steel surface. Apply light to moderate pressure to remove the surface coating without deeply gouging the steel.

- Observe the Color and Material Removed: After scratching the surface, closely observe the material that has been removed and the color of the underlying layer.

Interpreting the Results

- Galvanized Steel: If the steel is galvanized, the scratch will reveal a shiny, silver-colored layer beneath the dull gray coating. This shiny layer is the zinc coating, which protects the steel underneath and indicates that galvanization has been applied.

- Non-Galvanized Steel: If the steel is non-galvanized, scratching the surface will not reveal a distinct coating layer. Instead, the color and texture of the scratched area will be consistent with the rest of the material, typically showing no differentiation.

By comparing the results of your scratch test with these interpretations, you can discern whether the steel in question has been galvanized.

Safety Considerations

When conducting a scratch test, it is crucial to take the following safety precautions:

- Use Gloves and Safety Goggles: Always wear gloves to protect your hands from sharp edges and safety goggles to shield your eyes from any metal particles that may be dislodged during the scratching process.

- Ensure Good Ventilation: If you are using sandpaper, ensure that the area is well-ventilated to prevent inhaling any fine metal dust that might be produced.

Following these safety measures will help you conduct the scratch test effectively and securely, ensuring that you can make an accurate assessment of whether the steel is galvanized.

Chemical Test

Preparing for the Chemical Test

Conducting a chemical test is another reliable method to determine if steel is galvanized. Here are the necessary items and safety measures for the test:

- Necessary Items:

- White vinegar or diluted muriatic acid solution: Both can effectively react with the zinc coating found on galvanized steel.

- Small brush: Useful for applying the vinegar or acid solution evenly over the steel surface.

- Safety gear: Gloves and goggles are essential to protect your skin and eyes from chemical exposure.

- Safety Measures:

- Caution against strong acids: Using strong acids can be hazardous. It is crucial to handle them with extreme care and only proceed if you have the proper protective equipment.

Performing the Chemical Test

Follow these step-by-step instructions to perform the chemical test:

- Apply the Acid Solution: Using the small brush, apply a small amount of white vinegar or diluted muriatic acid to the steel surface. Make sure to cover a small, unobtrusive area so as not to damage the integrity of the steel product.

- Allow Time for Reaction: Let the solution sit on the steel surface for a few minutes. This waiting period enables the acid to react with any zinc coating present.

- Observe the Reaction: Carefully observe the area for bubbling or fizzing, which indicates a chemical reaction.

Interpreting the Results

- Galvanized Steel: If the steel is galvanized, you will see bubbling or fizzing as the acid reacts with the zinc coating. This reaction occurs because the acid breaks down the zinc, producing hydrogen gas.

- Non-Galvanized Steel: In contrast, non-galvanized steel will exhibit little to no reaction with the acid. Since there is no zinc coating to react with, the acid will not cause significant bubbling or fizzing.

By comparing these observations, you can determine whether the tested steel piece is galvanized.

Safety Considerations

When conducting the chemical test, it is critical to prioritize safety. Follow these guidelines to ensure a secure testing environment:

- Use Protective Gear: Always wear gloves and safety goggles to prevent chemical burns and eye injury. Acid splashes can cause severe damage to unprotected skin and eyes.

- Ensure Good Ventilation: Perform the test in a well-ventilated area or outdoors to avoid inhaling any fumes produced during the chemical reaction.

- Neutralize and Dispose of Chemicals Properly: After the test, neutralize the acid with a mixture of baking soda and water. This neutralization process renders the remaining acid harmless. Dispose of the neutralized solution and any contaminated materials according to local hazardous waste disposal guidelines.

By adhering to these safety precautions and procedural steps, you can effectively and safely use the chemical test to identify galvanized steel.

Conductivity Test

Understanding Conductivity Differences

Electrical conductivity is a critical factor in distinguishing between galvanized and non-galvanized steel. Zinc, which is used in the galvanization process, affects the electrical conductivity of steel.

The presence of a zinc coating generally lowers the overall conductivity of the steel because zinc is less conductive than the steel substrate. By measuring the electrical conductivity, you can determine the presence of a zinc layer, thus identifying whether the steel is galvanized.

Conducting the Conductivity Test

To perform the conductivity test, gather the following tools and follow these instructions:

- Necessary Tools:

- A multimeter is set to measure conductivity.

Step-by-Step Instructions:

- Prepare the Multimeter: Set your multimeter to the conductivity measurement mode.

- Place the Probes on the Steel Surface: Position the multimeter probes on the steel surface, ensuring that they are firmly in contact.

- Measure the Conductivity: Record the conductivity readings displayed on the multimeter.

- Compare to Standard Values: Compare the obtained readings to standard conductivity values for both galvanized and non-galvanized steel.

Interpreting the Results

- Galvanized Steel: Galvanized steel will typically display slightly lower conductivity readings due to the insulating effect of the zinc coating. Zinc’s lower electrical conductivity compared to bare steel results in a diminished overall conductivity measurement.

- Non-Galvanized Steel: In contrast, bare steel will exhibit higher conductivity readings. The absence of a zinc coating means that the multimeter measures the conductivity of the steel itself, which is higher than that of zinc-coated steel.

By following these guidelines and understanding the differences in conductivity, you can effectively use the conductivity test to determine whether a steel piece is galvanized.

Professional Testing Methods

Advanced Testing Techniques

X-ray fluorescence (XRF) Analysis

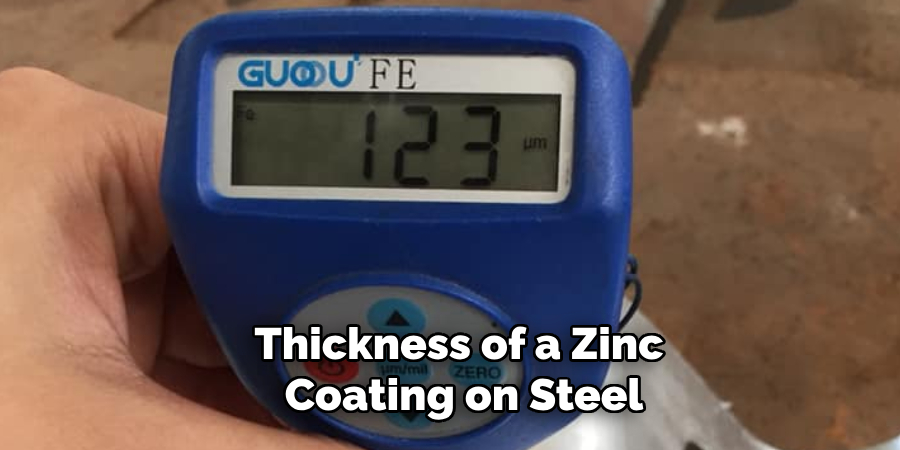

X-ray fluorescence (XRF) analysis is a professional method used to accurately identify the presence and thickness of a zinc coating on steel. This technique involves exposing the steel to X-rays, which causes the elements within the material to emit secondary (or fluorescent) X-rays.

The zinc coating can be precisely detected and quantified by examining the energy spectrum of these fluorescent X-rays.

Spectrometry

Spectrometry, including methods like Optical Emission Spectroscopy (OES), is another advanced testing technique ideal for identifying galvanization. This method uses a high-energy source to excite atoms in the steel, causing them to emit light at characteristic wavelengths.

By analyzing these wavelengths, professionals can determine the exact composition of the steel surface, confirming the presence of zinc.

When to Seek Professional Help

Precise identification of galvanized steel is crucial in situations involving structural applications or safety-critical components where material integrity is paramount. In such cases, it’s advisable to contact metallurgical labs or utilize specialized testing equipment to ensure accurate results and maintain safety standards.

Frequently Asked Questions About Identifying Galvanized Steel

What Is Galvanized Steel?

Galvanized steel is steel coated in a layer of zinc to protect it from rust and corrosion. This zinc layer acts as a protective barrier, giving the steel added durability and longevity, especially in environments prone to moisture.

How Can I Tell if Steel Is Galvanized?

You can identify galvanized steel through several methods, such as visual inspection for a distinctive spangled appearance, chemical testing for reactions with acid, and conductivity testing for lower electrical conductivity due to the zinc layer. Professional techniques like X-ray fluorescence (XRF) analysis and spectrometry can provide precise identification.

What Do the Visual Signs of Galvanized Steel Look Like?

Galvanized steel often features a spangled pattern on its surface due to the crystallization of the zinc coating. It may also appear slightly dull or greyish compared to non-galvanized steel’s more reflective and polished finish.

Is It Safe to Perform an Acid Test on Steel at Home?

Yes, it is safe to conduct an acid test on steel at home, provided that you follow proper safety precautions. Always use protective gear such as gloves and safety goggles, ensure good ventilation, and neutralize and dispose of the acid properly after the test.

How Does the Conductivity Test Work for Identifying Galvanized Steel?

In a conductivity test, a multimeter measures electrical conductivity. Because zinc has lower conductivity than steel, galvanized steel will show lower conductivity readings compared to non-galvanized steel. This difference in readings helps identify the presence of a zinc coating.

Why Might I Need Professional Testing Methods?

Professional testing methods like XRF analysis and spectrometry offer precise identification of galvanized steel. These advanced techniques are crucial in structural applications or safety-critical components where ensuring material integrity and compliance with standards is necessary. Seeking professional help guarantees accurate results and safety.

Conclusion

In conclusion, determining if steel is galvanized can be effectively achieved using several methods. Visual inspection allows for the identification of the characteristic spangled appearance of galvanized steel.

The magnetic test provides insight into the difference in magnetic attraction due to the zinc coating. The scratch test involves scratching the steel surface to check for the underlying zinc layer, while the chemical test reveals a reaction with the zinc coating. Lastly, the conductivity test measures electrical conductivity to differentiate between galvanized and non-galvanized steel.

Proper identification is essential for ensuring the longevity and suitability of steel for various applications. Selecting the appropriate method for “how to tell if steel is galvanized” depends on the tools available and adhering to safety considerations.

Whether using simple visual and magnetic tests or advanced methods like XRF analysis, accurate identification helps maintain structural integrity and optimize material use in projects.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.