When performing engine maintenance or repairs, ensuring the cylinder head bolts are properly tightened is crucial for preventing leaks and maintaining engine performance. While using a torque wrench is the standard method for achieving the correct tension, it is possible to tighten cylinder head bolts effectively without one. This guide will outline practical steps and tips how to tighten cylinder head bolts without torque wrench.

The Importance of Correctly Tightening Cylinder Head Bolts

Properly tightening cylinder head bolts is essential for maintaining the integrity and performance of an engine. These bolts play a crucial role in securing the cylinder head to the engine block, creating a seal that prevents the leakage of gases, coolant, and oil. If the bolts are overtightened, it can lead to thread damage or even warping of the cylinder head, resulting in costly repairs. On the other hand, insufficient tightening may cause gasket failure, allowing harmful leaks and reducing engine efficiency. Achieving the correct tension ensures optimal compression within the cylinders and protects the engine from unnecessary wear and tear, prolonging its lifespan and reliability.

Tools and Materials Needed

To tighten cylinder head bolts without a torque wrench, you will need the following tools and materials:

- Socket Set and Ratchet: A quality socket set is essential to fit the specific size of your cylinder head bolts.

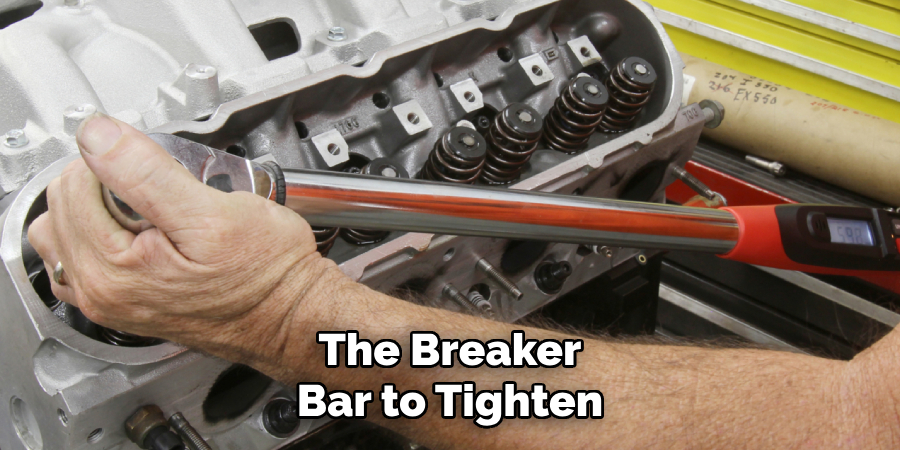

- Breaker Bar (Optional): For better leverage when tightening the bolts.

- Penetrating Oil: Helps loosen any stuck bolts or clean threads before tightening.

- Straightedge and Feeler Gauge: To check for any warping on the cylinder head or engine block.

- Permanent Marker or Chalk: For marking bolts to monitor incremental tightening.

- User Manual or Bolt Tightening Diagram: This will help you follow the correct tightening sequence.

Make sure all tools and materials are in good condition and accessible before you start. Having everything ready will ensure a smoother and more efficient process.

10 Methods How to Tighten Cylinder Head Bolts without Torque Wrench

1. Use a 3-Stage Tightening Process

One of the simplest and most effective methods to tighten cylinder head bolts without a torque wrench is by using a multi-stage tightening process. This approach involves tightening the bolts in three or more stages to ensure even pressure across the cylinder head. Start by hand-tightening each bolt in a crisscross pattern to avoid warping the head. Afterward, progressively tighten each bolt in a series of stages. Tighten them incrementally until you feel resistance or reach a point where it feels firm but not too tight. Finally, give each bolt a final snugging in a crisscross pattern to ensure uniformity across the cylinder head.

2. Tighten by Feel Using Standard Wrenches

If you don’t have a torque wrench but are experienced with engine assembly, you can rely on your sense of feel. This method requires you to use a regular wrench or socket to tighten the bolts gradually. Begin by hand-tightening the bolts to their lowest resistance point. Then, using a wrench, tighten each bolt in a crisscross pattern, moving from the middle bolts outward to ensure even pressure. While this method lacks precision, experienced mechanics can often feel when a bolt is adequately tightened based on the resistance they encounter as they turn it. Be cautious with this method, as it is easy to overtighten or under-tighten the bolts without the proper gauge.

3. Utilize a Makeshift Torque Measurement Tool

If you don’t have a torque wrench but are comfortable with making a DIY solution, you can try to create a makeshift torque measurement tool using a breaker bar and a scale. A breaker bar is a long-handled wrench that provides greater leverage, which allows you to apply more force with less effort. To use this method, attach the breaker bar to the bolt and place a known weight or scale to measure the force. For example, you could use a spring scale to measure how much force you’re applying while tightening the bolt. This can help you estimate the required torque, although it may not be as precise as a proper torque wrench.

4. Tighten with a Ratchet Wrench and Socket

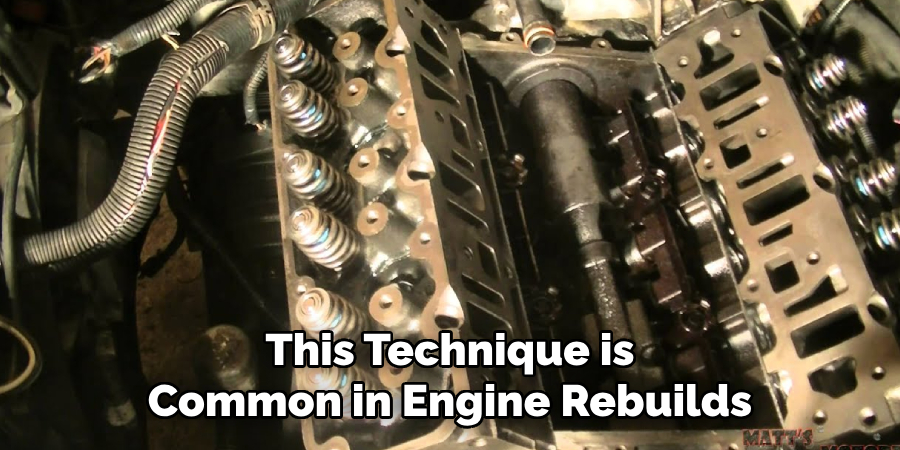

A ratchet wrench and socket set can be another tool for tightening cylinder head bolts without a torque wrench. Although it lacks the precision of a torque wrench, a ratchet wrench can provide sufficient leverage when used in a controlled, methodical manner. Tighten each bolt in a crisscross pattern to evenly distribute pressure across the head. Like the method of tightening by feel, you’ll need to rely on your experience and the resistance you feel when tightening the bolt. This technique is common in engine rebuilds where a torque wrench might not be available, but it requires attention to avoid overtightening.

5. Use the Manufacturer’s Recommended Tightening Sequence

Following the manufacturer’s recommended tightening sequence is vital, regardless of the tools you’re using. Most cylinder heads have a specific pattern that helps distribute the pressure evenly, preventing warping or uneven sealing. Typically, this involves tightening the bolts in a crisscross or spiral pattern starting from the center of the cylinder head and working outward. By adhering to this tightening sequence, you help to ensure that the cylinder head bolts are tightened uniformly, even without a torque wrench. Always consult the engine manual for the precise sequence to follow.

6. Tighten by “Angle Tightening”

Another method for tightening cylinder head bolts without a torque wrench is to use an angle-tightening technique, where you tighten the bolt by a certain angular increment rather than by torque. This is often done by rotating the bolt by a specified number of degrees after reaching a point of hand-tightness. If you have a protractor or an angle gauge, you can measure the angle of rotation as you tighten each bolt. For example, you might tighten each bolt to 90 degrees after it is initially hand-tightened. This method is commonly used in high-performance engines and can be effective as long as you are careful and consistent with the angular increments.

7. Use a Breaker Bar for Leverage

If you lack a torque wrench but have access to a breaker bar, this tool can help you apply more controlled force when tightening cylinder head bolts. A breaker bar is a long-handled wrench that offers increased leverage, allowing you to apply more torque without excessive effort. Start by hand-tightening the bolts to ensure they are properly seated. Then, use the breaker bar to tighten each bolt gradually, starting in the middle and working outward in a crisscross pattern. The additional length of the breaker bar helps apply even, controlled pressure, which can be particularly useful when a torque wrench isn’t available.

8. Monitor the Bolt Resistance

As you tighten the cylinder head bolts, you can monitor the resistance of the bolt. When you reach a certain level of resistance and it begins to feel “snug,” stop tightening. While this method does not provide the precision of a torque wrench, it can help you gauge when the bolt has reached an appropriate level of tightness. You should feel significant resistance before the bolt begins to turn more easily. Be cautious to avoid overtightening, which could cause the threads to strip or the cylinder head to warp.

9. Use a Hydraulic Jack to Apply Even Pressure

In some cases, using a hydraulic jack to apply controlled pressure can help in tightening cylinder head bolts. Place the jack underneath the vehicle’s frame or another stable area to apply steady force. This method is often used in automotive repair and engine building when tools like a torque wrench aren’t available. By applying controlled pressure gradually, the bolts will tighten evenly across the cylinder head. This method requires careful attention to the pressure applied, and it’s important to avoid exceeding the necessary force that could damage the bolts or the cylinder head.

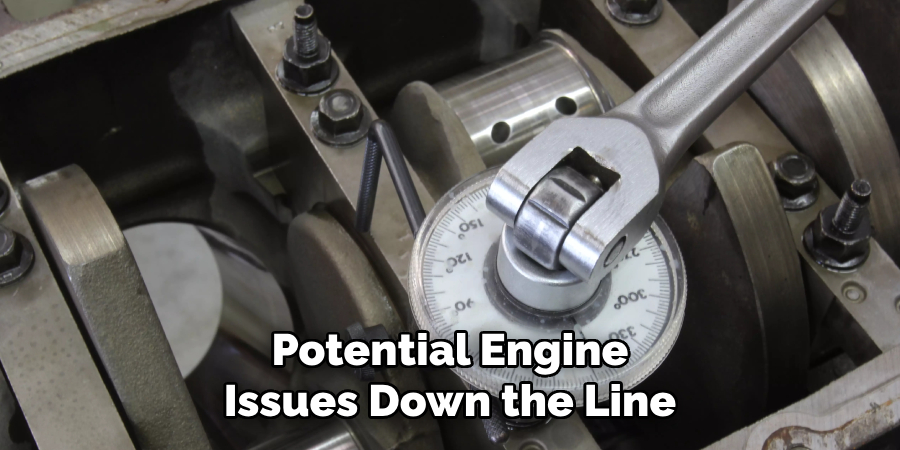

10. Perform Final Checks with a Torque Wrench (If Available Later)

While this method assumes you may not have access to a torque wrench initially, it’s always a good idea to double-check the tightness of the cylinder head bolts once you have access to the proper tool. If you’re working on a rebuild or an engine assembly, and a torque wrench is unavailable at first, finish tightening the bolts using other methods and then return to the job once you have a torque wrench. This will allow you to ensure the cylinder head bolts are precisely torqued to the manufacturer’s specifications, preventing potential engine issues down the line.

Conclusion

Tightening cylinder head bolts without a torque wrench can be challenging, but with the proper techniques and attention to detail, it is possible to achieve satisfactory results. Methods such as using a breaker bar, angle-tightening, and following the manufacturer’s recommended tightening sequence can help ensure even pressure and prevent damage to the engine. However, it is always ideal to use a torque wrench when possible for precise measurements and optimal performance. Follow these simple instructions outlined in this blog post about how to tighten cylinder head bolts without torque wrench, and you’ll be able to get the job done with ease.

Edmund Sumlin is a skilled author for Metal Fixes, bringing 6 years of expertise in crafting a wide range of metal fixtures. With a strong background in metalwork, Edmund’s knowledge spans various types of fixtures, from decorative pieces to functional hardware, blending precision with creativity. His passion for metalworking and design has made him a trusted resource in the industry.

Professional Focus:

- Expert in Metal Fixtures : Edmund aesthetic specializes in creating durable and innovative metal fixtures, offering both appeal and functionality. His work reflects a deep understanding of metalworking techniques and materials.

- Sustainability Advocate : He is dedicated to using sustainable practices, ensuring that every fixture is crafted with eco-friendly methods while maintaining high-quality standards.

In his writing for Metal Fixes, Edmund provides valuable insights into the latest trends, techniques, and practical advice for those passionate about metal fixtures, whether they are professionals or DIY enthusiasts. His focus on combining artistry with engineering helps others discover the true potential of metal in design.