Are you curious about the mysterious world of metalworking and the ways to make metals look and function their best? Anodizing steel may be the answer! Metals like aluminum, titanium, and steel can all benefit from this electrochemical process that adds desirable colors, protects against rust or corrosion, and increases durability and hardness – making it a great way to customize your next metalworking project.

If you’re ready to dive into anodizing for yourself or you’d just like a crash-course introduction on how it works, read on! We’ll explore everything about how to anodize steel, from chemical reactions behind anodizing steel to common pitfalls when getting started so you can become an expert in no time.

Why is It Important to Anodize Steel?

1 . To Increase Corrosion Resistance

Corrosion is a chemical reaction between a metal and its environment that results in damage to the metal. When steel is exposed to moisture, oxygen, or other corrosive substances, it can start to rust and eventually deteriorate.

Anodizing creates an oxide layer on the surface of the steel, which acts as a barrier against corrosion. This protective layer can significantly increase the lifespan of steel, making it an essential process for various industries that regularly use steel materials.

2 . To Enhance Durability

Anodizing also increases the durability and strength of steel. The oxide layer formed during the anodizing process is much harder than the base metal and provides a higher level of abrasion resistance.

This makes anodized steel ideal for applications that require high durability, such as in the aerospace and automotive industries. Additionally, anodizing can improve the fatigue strength of steel, making it less prone to cracking and other forms of damage.

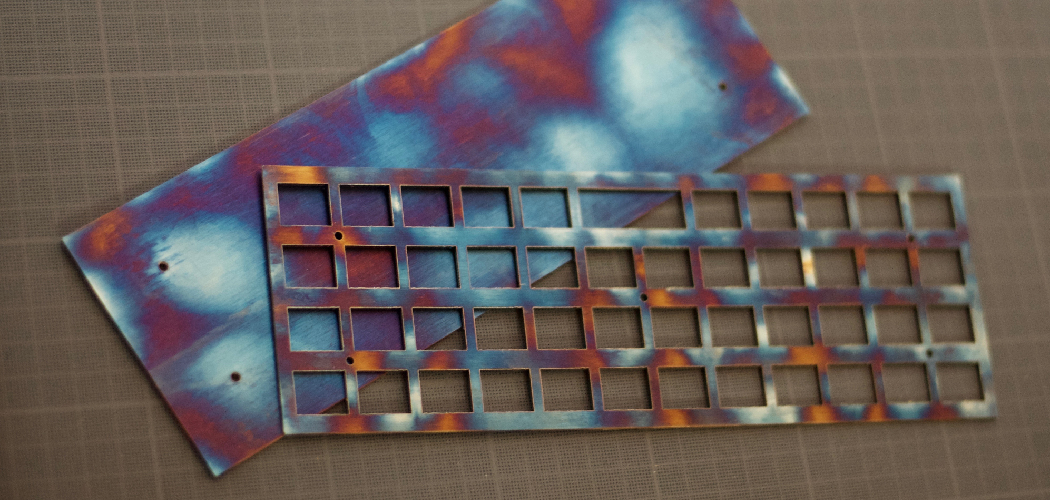

3 . To Improve Aesthetic Appeal

Not only does anodizing provide practical benefits, but it also enhances the appearance of steel. The anodizing process allows for a wide range of color options, giving steel a sleek and modern look. The oxide layer can also be dyed to create vibrant and long-lasting colors, making anodized steel perfect for architectural applications or decorative purposes.

4 . To Increase Electrical Insulation

Anodizing creates a non-conductive barrier on the surface of steel, making it an excellent electrical insulator. This property is crucial for industries that use steel in electronic devices or components. The oxide layer not only protects against corrosion but also prevents unwanted electrical currents from passing through the material, ensuring the safety and functionality of the final product.

5 . To Reduce Friction and Improve Lubrication

Anodized steel has a smoother surface than untreated steel, which reduces friction and improves lubrication. This is especially beneficial in applications that require sliding or moving parts, such as in industrial machinery or automotive engines. The anodized layer also has a lower coefficient of friction, making it more resistant to wear and tear.

How to Anodize Steel in 5 Easy Steps

Step 1: Clean the Steel

Before proceeding with anodizing steel, it is crucial to ensure that the surface of the steel is clean and free from any dirt, oil, or other contaminants. This can be achieved by using a degreaser or soap and water to thoroughly clean the steel.

Step 2: Prepare the Anodizing Solution

The next step is to prepare the anodizing solution. This can be done by mixing 1 part sulfuric acid with 10 parts distilled water. It is important to wear protective gear, such as gloves and goggles while handling the solution.

Step 3: Anodize the Steel

Once the steel has been cleaned and the anodizing solution prepared, it is time to immerse the steel in the solution. This can be done by using a tank or container that is resistant to acid. The steel should be completely submerged in the solution.

Step 4: Apply Electrical Current

To complete the anodizing process, an electrical current needs to be applied to the steel. This can be achieved by connecting the positive terminal of a power supply to the steel and the negative terminal to a conductive material, such as lead or graphite, that is immersed in the anodizing solution.

Step 5: Rinse and Seal

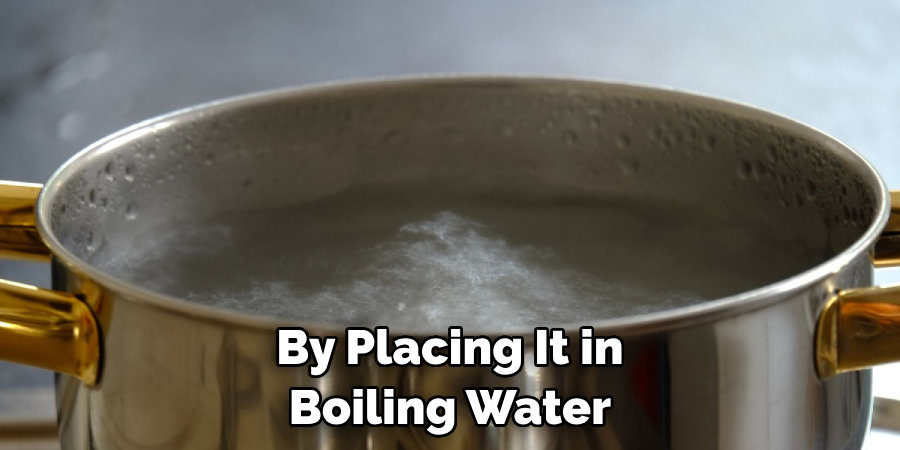

After the desired level of anodization has been achieved, remove the steel from the solution and rinse it thoroughly with water. This will help neutralize any remaining acid on the surface. Finally, seal the anodized steel by placing it in boiling water or using a commercial sealant.

Some Additional Tips to Anodize Steel

1 . Do Not Use Stainless Steel for Anodizing

Stainless steel is not a good metal to anodize. The chromium in stainless steel prevents the surface of the metal from being properly etched, which is essential for creating an even layer of oxide coating. Therefore, it is best to avoid using stainless steel for anodization.

2. Clean and Degrease the Metal

Before anodizing the steel, it is important to make sure that the surface is clean and free of any oils or debris. Use a degreaser specifically designed for metal surfaces to thoroughly clean the steel.

3. Choose the Right Anodizing Solution

There are different types of anodizing solutions available in the market, such as sulfuric acid, chromic acid, and phosphoric acid. Each solution has its advantages and disadvantages, so it is important to choose the right one for your specific needs.

4. Use Proper Safety Measures

Anodizing solutions can be hazardous if not handled properly. Make sure to wear protective gear such as gloves, goggles, and aprons while working with anodizing solutions. Also, make sure to work in a well-ventilated area and follow all safety precautions.

5. Experiment with Different Colors

Anodizing allows you to add color to your steel by using dyes during the anodization process. Don’t be afraid to experiment with different colors and get creative with your designs. Just make sure to use acid-resistant dyes specifically designed for anodizing.

6. Practice and Learn from Mistakes

Anodizing steel takes practice and mistakes are bound to happen. Don’t be discouraged if your first few attempts don’t turn out perfectly. Learn from your mistakes and keep practicing to improve your skills.

Frequently Asked Questions

What Precautions Should I Take When Doing Steel Anodizing?

Steel anodizing involves the use of hazardous chemicals and electricity. Therefore, it is important to take proper precautions before, during, and after the process. Some important safety measures include:

- Wearing protective gear such as gloves, goggles, and aprons

- Working in a well-ventilated area

- Avoiding contact with the anodizing chemicals

- Keeping a fire extinguisher nearby in case of any accidents

- Familiarizing yourself with emergency procedures in case of chemical spills or electrical malfunctions

How Do I Prepare the Steel for Anodizing?

Before starting the anodizing process, it is important to properly prepare the steel. This includes:

- Cleaning the steel surface to remove any dirt, oil, or other contaminants

- Stripping any existing coatings or paint from the steel

- Deoxidizing the steel surface using a strong chemical solution

Can Any Type of Steel be Anodized?

Not all types of steel are suitable for anodizing. Only certain types of stainless steel such as 304 and 316 can be anodized, as well as certain types of aluminum. It is important to check the composition of the steel before attempting anodizing.

What Factors Affect the Anodizing Process?

Several factors can affect the outcome of the anodizing process on steel. These include:

- The composition and quality of the steel

- The type and concentration of chemicals used in the anodizing process

- The voltage and current used during the anodizing process

- The duration of the anodizing process

How Do I Achieve Different Colors on Anodized Steel?

The color of anodized steel can be altered by changing the thickness of the oxide layer formed on the surface. This can be achieved by adjusting the duration and voltage used during the anodizing process. Different colors can also be achieved by dyeing the anodized steel.

What are Some Common Applications for Anodized Steel?

Anodized steel has a variety of applications in industries such as aerospace, automotive, and construction. It is often used for decorative purposes due to its ability to achieve vibrant and long-lasting colors. It is also used for its corrosion resistance and durability in harsh environments.

Where Can I Learn More About Anodizing Steel?

There are many resources available online for learning more about anodizing steel. Some helpful sources include industry websites, instructional videos, and professional workshops or courses. It is important to thoroughly research and understand the process before attempting it on your own.

Conclusion

Anodizing steel is a complex process, but with the right instructions and techniques, it can be done correctly. By following these simple steps, you will have a better understanding of how to anodize steel and have it turn out exactly as you envisioned. As with any do-it-yourself project, safety should always come first – make sure that precautions are taken so you don’t put yourself at risk.

Now you know how to anodize steel! Best of luck if you decide to try to anodize steel on your own – if those mirror finishes don’t happen for you on your first try, keep practicing! And remember, no matter what happens: keep creating beautiful pieces with metal!